A1A shaft type elastic suspension turning frame for high speed locomotive

A technology for high-speed locomotives and bogies, used in bogies, railway car body parts, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

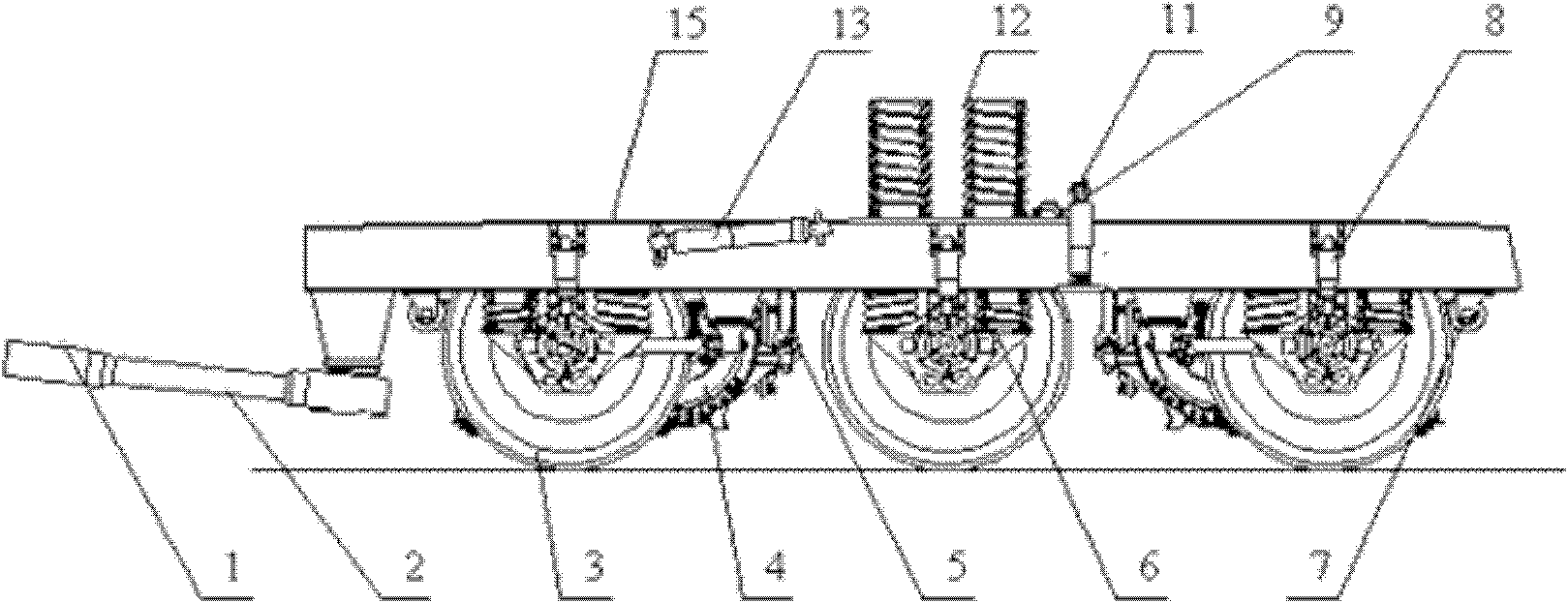

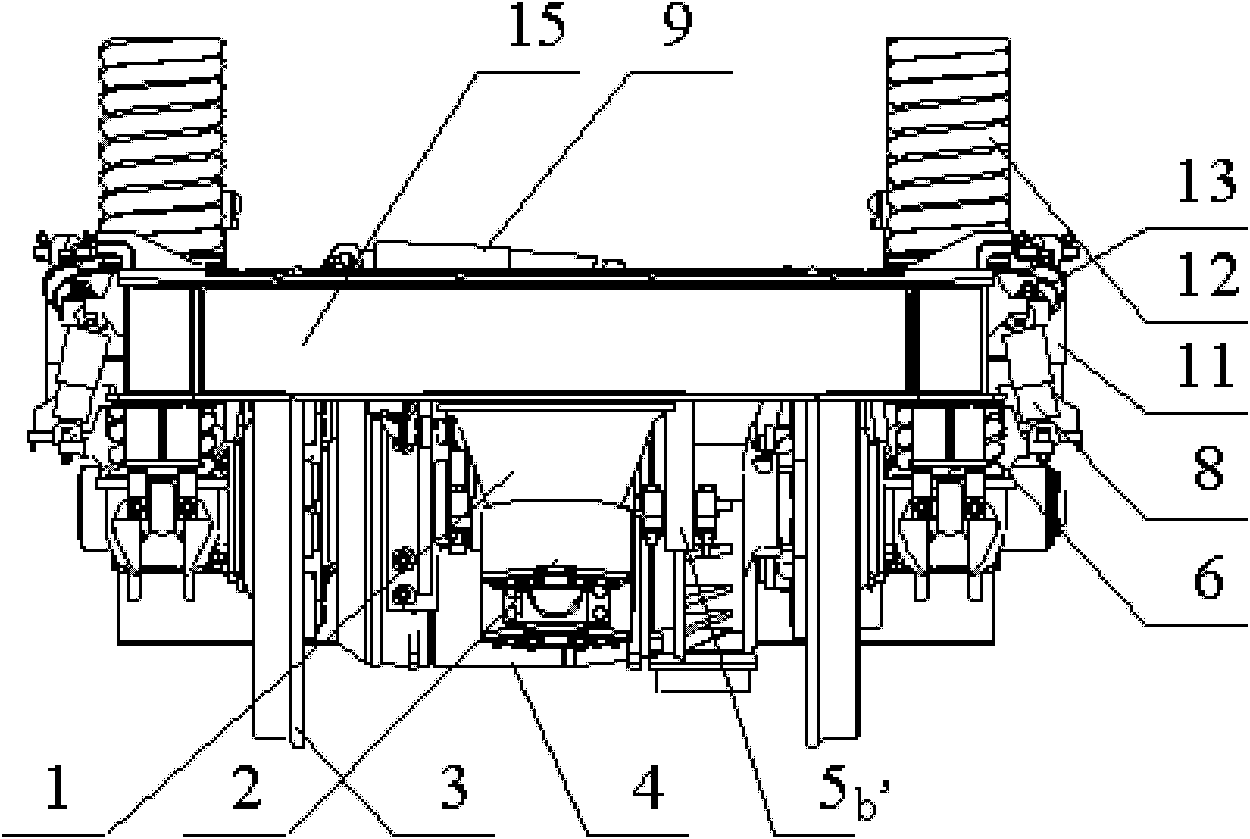

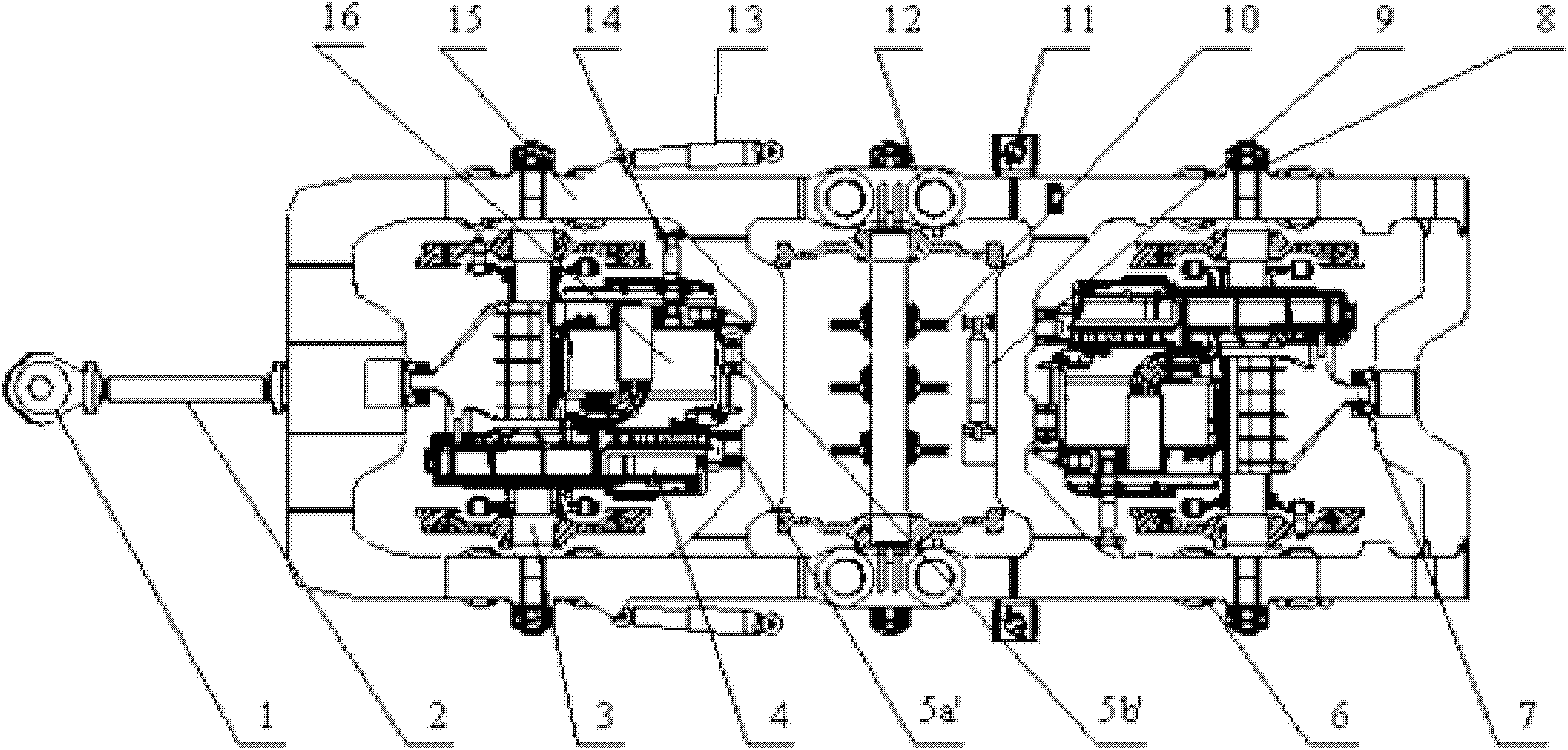

[0013] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] Such as figure 1 As shown, in the figure: 1- traction seat at the bottom of the vehicle; 2- draw bar; 3- wheel pair; 4- driving device; 1st-series vertical shock absorber; 9-secondary transverse shock absorber; 11-secondary vertical shock absorber; 12-secondary spring; 13-anti-snake shock absorber; 15-frame, 16-drive motor. The bogie adopts the matching of primary springs 6 hard and secondary springs 12 soft and long single drawbar 2; the front and rear wheel pairs of the bogie are power-driven wheel pairs, and the driving units of the front and rear wheel pairs have the same structure and are obliquely symmetrical to the center of the bogie Arrangement, the driving unit is mainly made up of the driving device 4 and the driving motor 16 that drives the driving device. The middle wheel pair does not have a driving device, but a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com