An EMU traction system with catenary and power pack hybrid power supply

A hybrid power supply and traction system technology, which is applied in the directions of engine-driven traction, AC induction motor traction, electric traction, etc., can solve the problems of inability to implement self-rescue in time, and the inability of EMUs to meet the operation requirements, and reduce power and volume. , the effect of reducing the design cost and the best power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

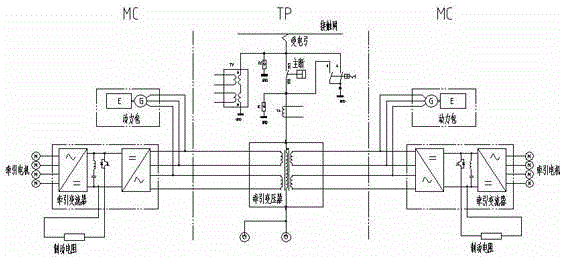

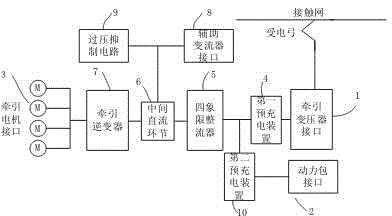

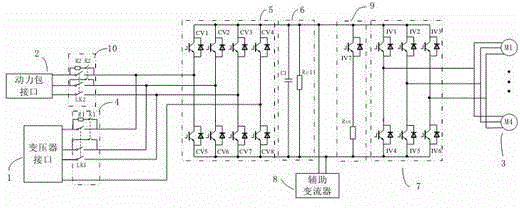

[0018] refer to figure 1 , the embodiment of the present invention mainly includes a traction transformer, a power pack, a traction converter, and a traction motor. The converter is connected to the traction motor. The function of the traction transformer is to step down the single-phase network voltage of the AC catenary as the input voltage of the traction converter. The traction converter then drives the traction motor to realize the traction of the EMU. The unit is composed of an internal combustion power pack, and the three-phase output of the generator is directly connected with the traction converter.

[0019] refer to figure 2 , image 3 , 1. Traction transformer interface 2. Power pack interface 3. Traction motor interface 4. First pre-charging device 5. Four-quadrant rectifier 6. Intermediate DC link 7. Traction inverter 8. Auxiliary converter interface 9. Overvoltage Suppression circuit 10. Second pre-charge means

[0020] The traction transformer interface 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com