An EMU traction system powered by hybrid power pack and energy storage device

A technology of energy storage device and hybrid power supply, which is applied in the direction of using engine-driven traction, AC induction motor traction, electric traction, etc. The best acceleration performance, reduce power and size, and achieve the effect of acceleration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

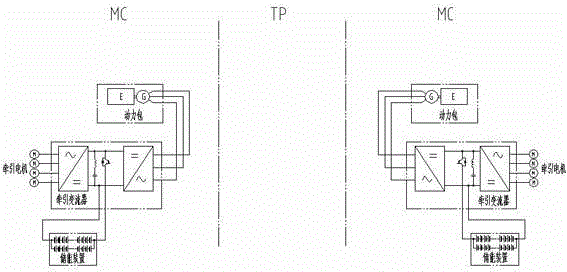

[0021] refer to figure 1 , the embodiment of the present invention includes a power pack, an energy storage device, a traction converter, and a traction motor, and the traction converter is connected to the traction motor; a diesel engine and a generator form an internal combustion power pack, and the three-phase output of the generator is directly connected to the traction converter The energy storage device is connected to the intermediate DC bus of the traction converter.

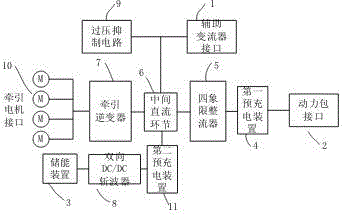

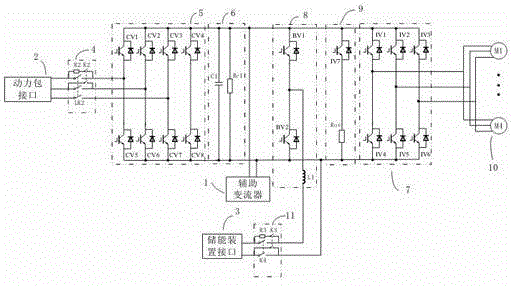

[0022] refer to figure 2 , image 3 , 1. Auxiliary converter interface 2. Power pack interface 3. Energy storage device interface 4. First pre-charging device 5. Four-quadrant rectifier 6. Intermediate DC link 7. Traction inverter 8. Bidirectional DC / DC chopper 9. Overvoltage suppression circuit 10. Traction motor interface 11. Second pre-charging device

[0023] The power pack interface 2 is connected to the input end of the four-quadrant rectifier 5, the energy storage device interface 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com