EMU traction system with hybrid power supply of catenary, power pack and energy storage device

An energy storage device and hybrid power supply technology, applied in battery/battery traction, AC induction motor traction, and engine-driven traction, etc., can solve problems such as braking energy consumption, energy waste, and inability to adapt to non-electrified railways. , to achieve the effect of accelerating performance, reducing power and volume, and achieving the best acceleration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

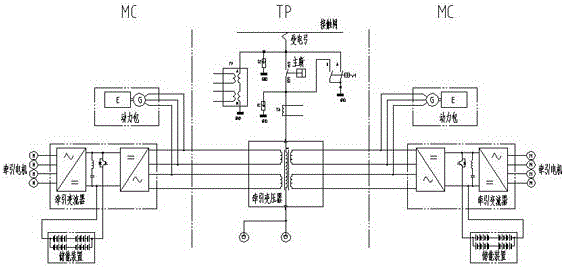

[0019] refer to figure 1 , the embodiment of the present invention mainly includes a traction transformer, a power pack, an energy storage device, a traction converter, and a traction motor. The traction converter is connected with the traction motor. The function of the traction transformer is to step down the single-phase network voltage of the AC catenary as the input voltage of the traction converter. The traction converter then drives the traction motor to realize the traction of the EMU. , the diesel engine and the generator form an internal combustion power pack, the three-phase output of the generator is directly connected to the traction converter, and the energy storage device is connected to the intermediate DC bus of the traction converter.

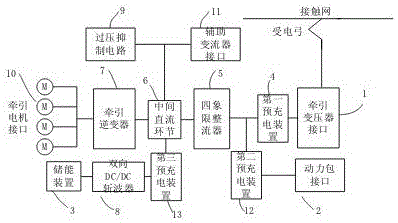

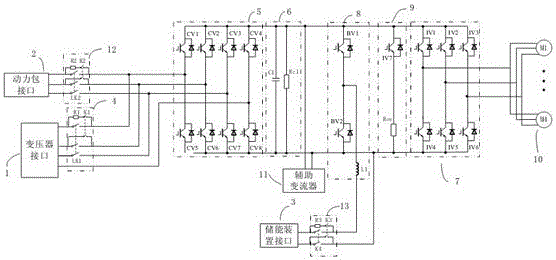

[0020] refer to figure 2 , image 3 , 1-traction transformer interface; 2-power pack interface; 3-energy storage device interface; 4-first pre-charging device; 5-four-quadrant rectifier; 6-intermediate DC link; 7-traction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com