Laying process for submarine pipeline traversing floating type production oil-storing device system

A technology for floating production and storage of oil and submarine pipelines, which is applied in the directions of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., to achieve the effect of simple process operation, low operation difficulty and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

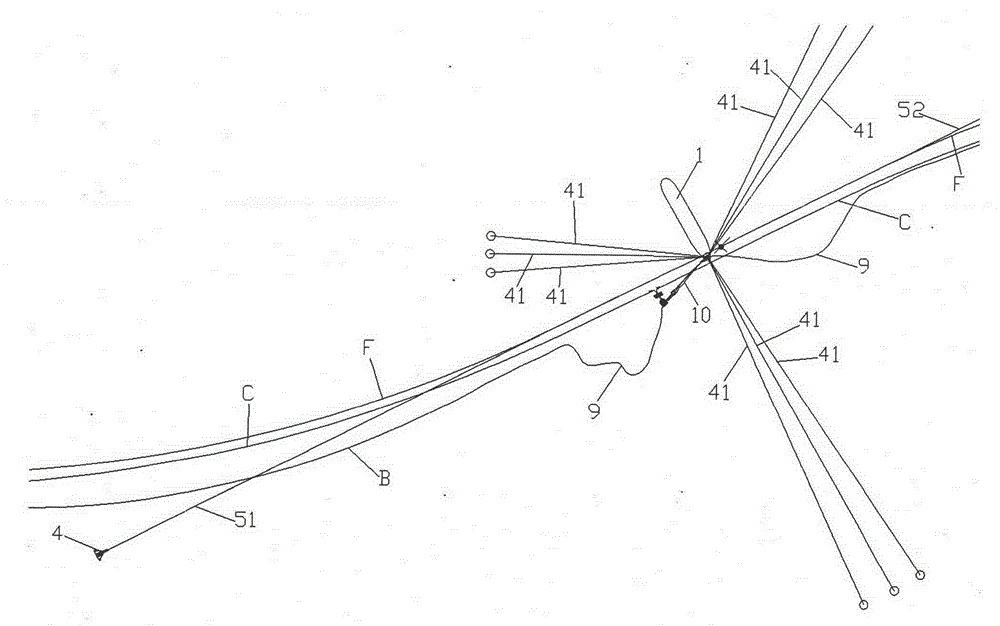

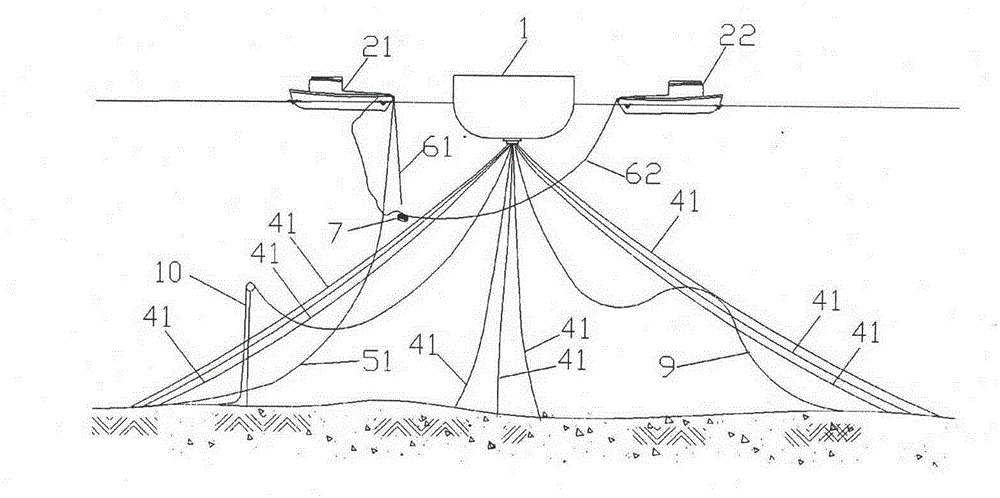

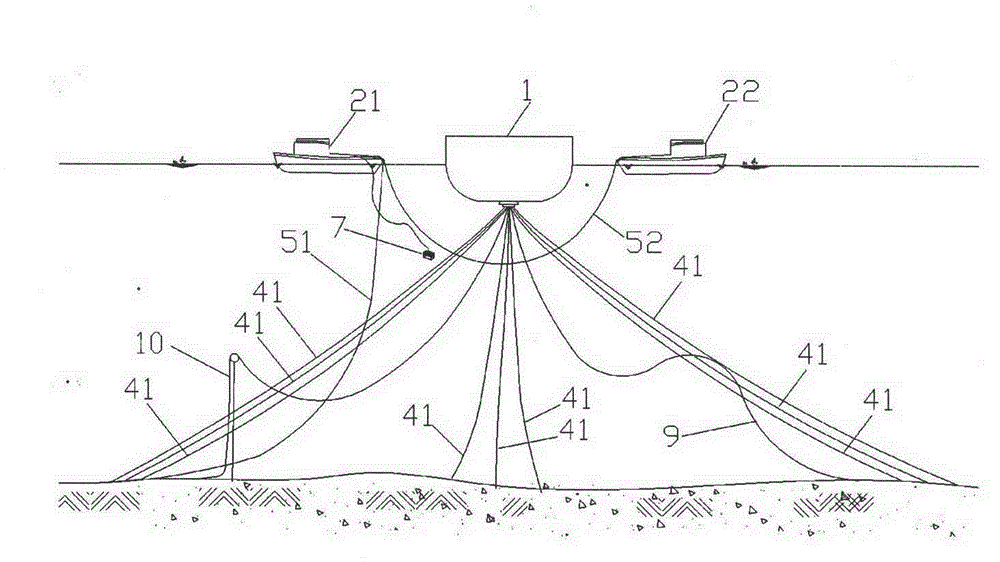

[0033] Such as Figure 1 to Figure 9 As shown, the laying process of the submarine pipeline passing through the floating production and storage device system of the present invention is characterized in that it includes installing the starting anchor, laying the starting cable, laying the crossing section pipeline, and dragging the crossing section pipeline through the floating production and storage device system (FPSO), the pipeline tension test of the crossing section and the steps of laying the submarine pipeline; among them:

[0034] The step of installing the initial anchor is to install the initial laying fixed point on the seabed. The fixed point is located on the extension line of the pipeline route in the crossing section. The initial anchor 4 is used as the initial laying fixed point. The machine places the starting anchor on the seabed, such as figure 1 shown;

[0035] The step of laying the starting cable is to lay the starting cable connected with the starting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com