Damage development mdel experimental device for process of embankment project piping-typed soils

A model test device and development process technology, applied in hydraulic models, measurement devices, fluid dynamics tests, etc., can solve the problems that cannot simulate the development process of piping, cannot test the dynamic change of seepage field, and cannot meet the research of piping damage in embankment engineering. needs and other issues, to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

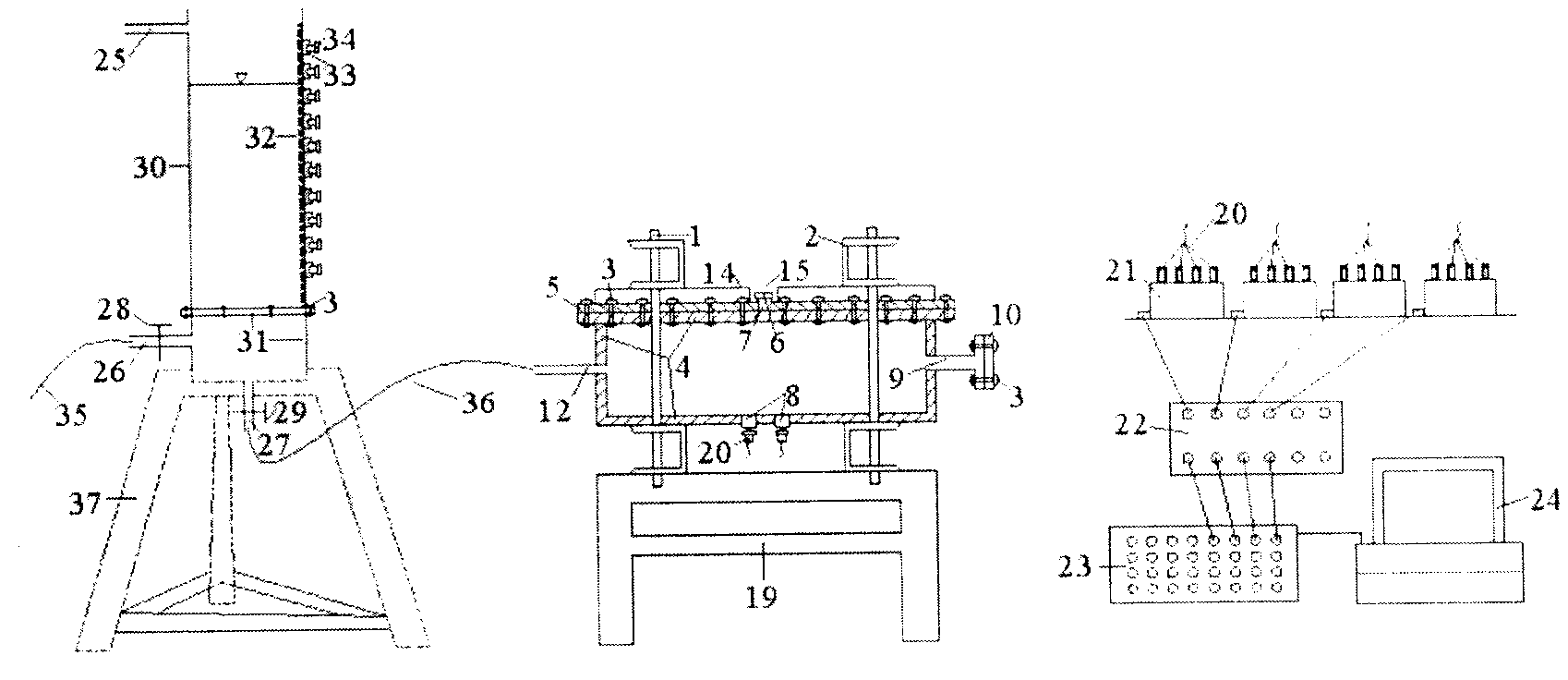

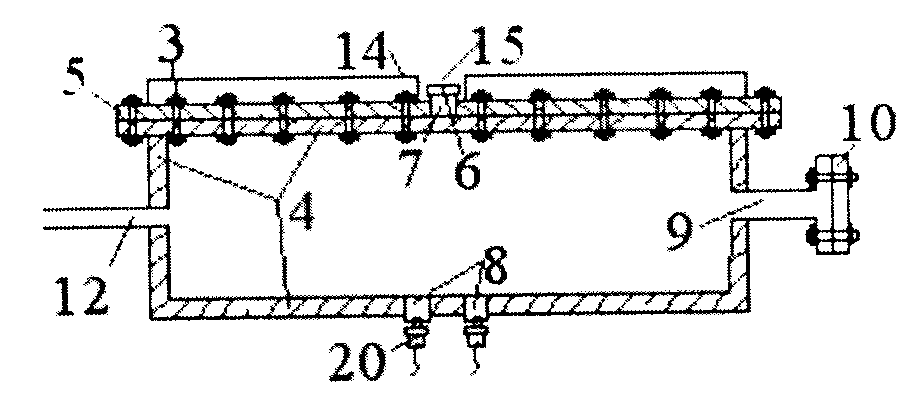

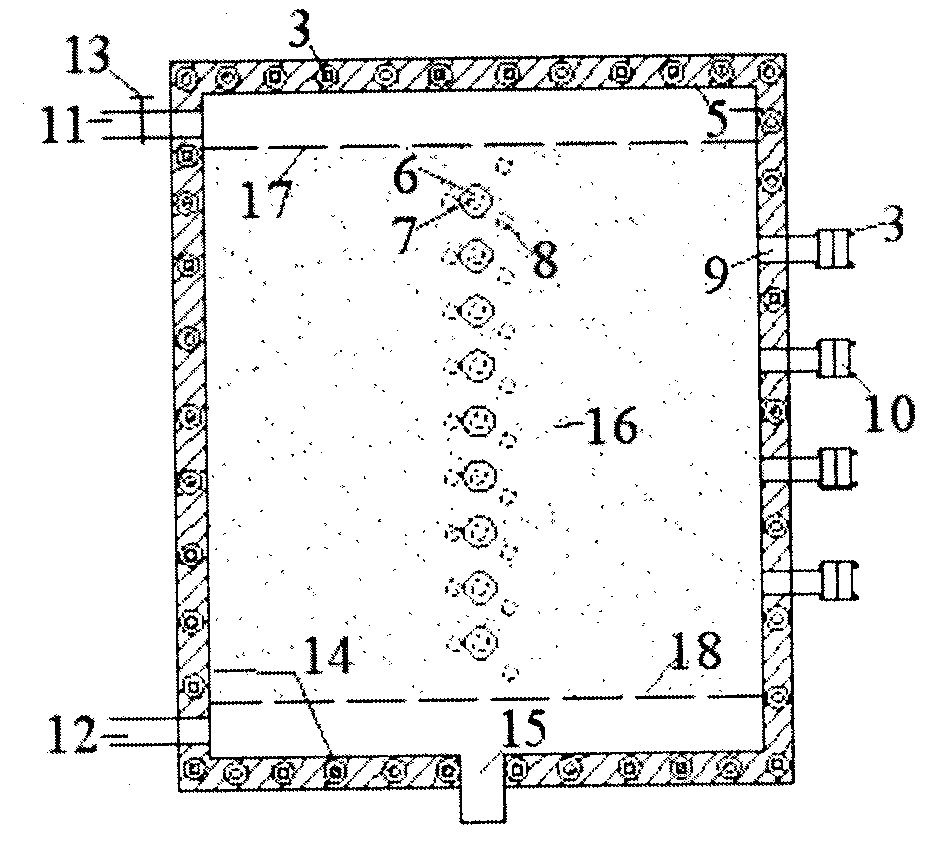

[0033] A model test device for simulating the development process of piping damage in embankment engineering, including a box-shaped tester, a variable water head water supply device, and a data acquisition device. There is a water inlet pipe 11 on the left side of the upstream of the box-shaped groove 4, which passes through a water inlet valve 13 and plastic water pipes 36 is connected with the iron cylinder water outlet pipe (27) of the variable water head water supply device, and there is a water outlet pipe 12 on the downstream left side; four sand-loading holes 9 are installed on the right side, and the sand-loading holes 9 are sealed with the hole cover plate 10, and the hole cover plate 10 is used Four bolts 3 are fixed; the middle part of the bottom plate of the box-shaped groove 4 is provided with a plurality of pressure measuring holes 8 along the upstream to the downstream, the upper part of the box-shaped groove 4 is sealed with the groove cover plate 5, and the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com