Method for improving adsorption performance of clay through loess additive

A technology of adsorption properties and additives, which is applied in the field of improving the adsorption properties of clay with loess additives, to achieve the effect of improving adsorption properties and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

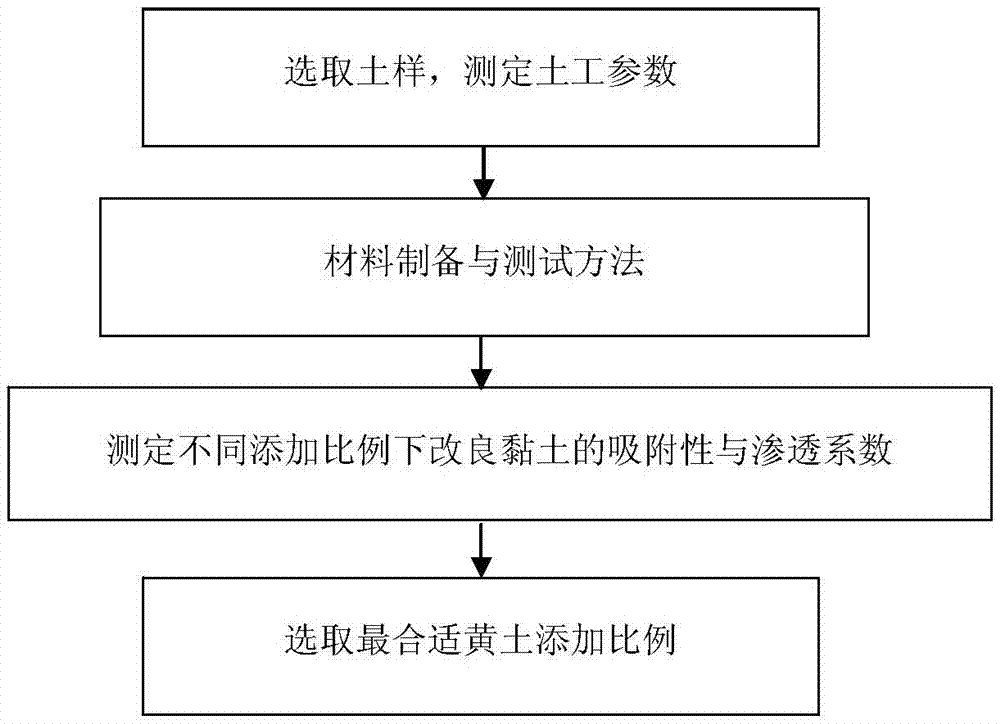

[0026] A method for improving the adsorption performance of clay by using loess additives, comprising the following steps:

[0027] Step 1, selecting soil material and measuring its geotechnical parameters;

[0028] Step 2, material preparation and testing;

[0029] Step 3, measuring the adsorption and permeability coefficient of the modified clay under different addition ratios;

[0030] Step 4: Select the most appropriate proportion of loess to improve the clay.

[0031] The soil materials selected in the step 1 are clay and loess obtained locally; the geotechnical parameters measured include particle gradation curve, permeability coefficient, liquid limit, plastic limit, maximum dry density, optimum water content, porosity and specific gravity.

[0032] Said step 2 material preparation comprises the following steps:

[0033] First, the soil sample is air-dried, sieved, dried, cooled to room temperature, and then stored in a plastic bag for later use;

[0034] Then, pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com