Connector assembly with a hook-in-place feel

A technology of connector components and hand feeling, which is applied in the direction of preventing wrong connection devices, devices for connecting, engaging/disconnecting connected parts, etc., which can solve the problem that the connector cannot judge whether the plug and socket are connected in place, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

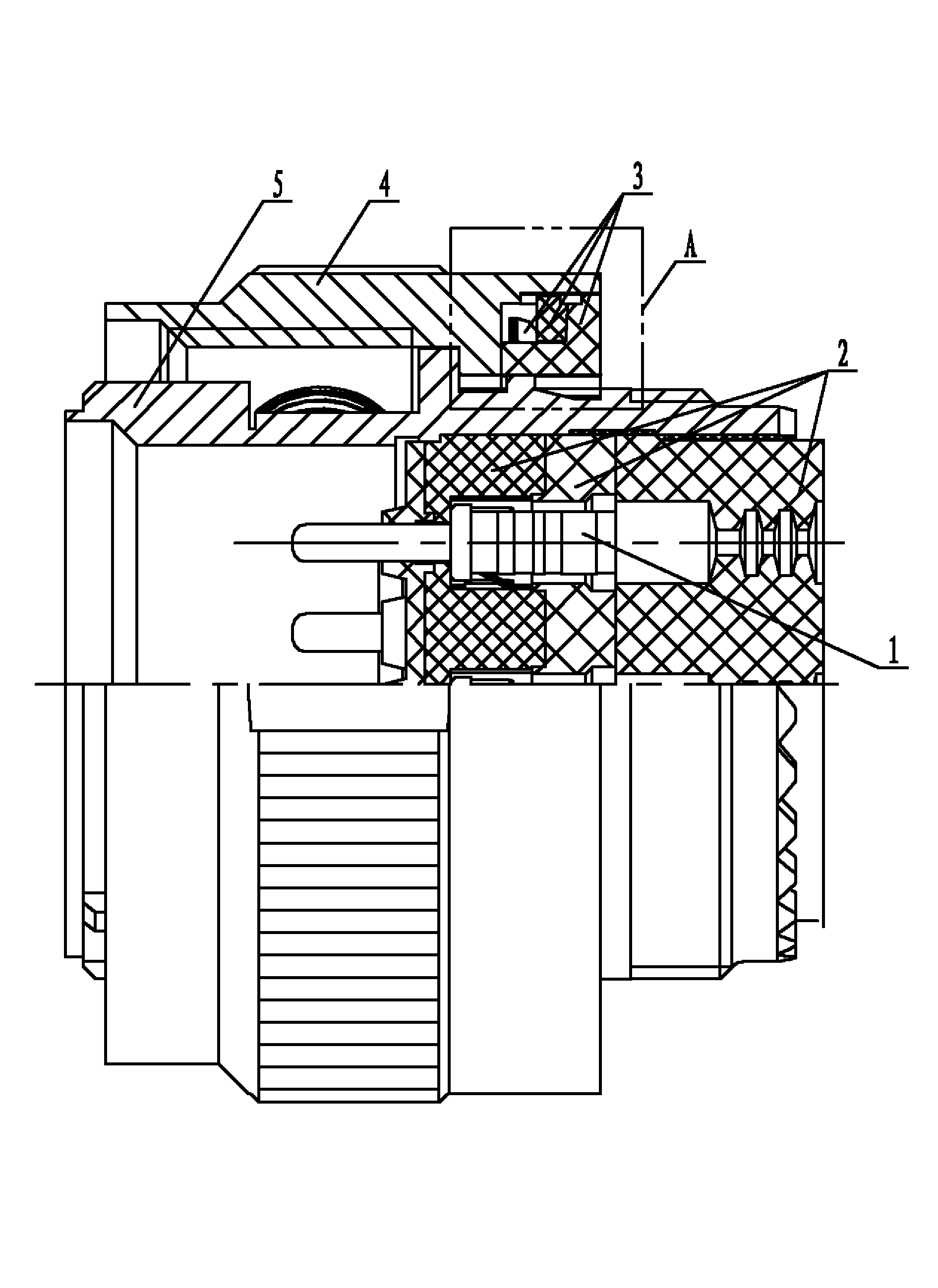

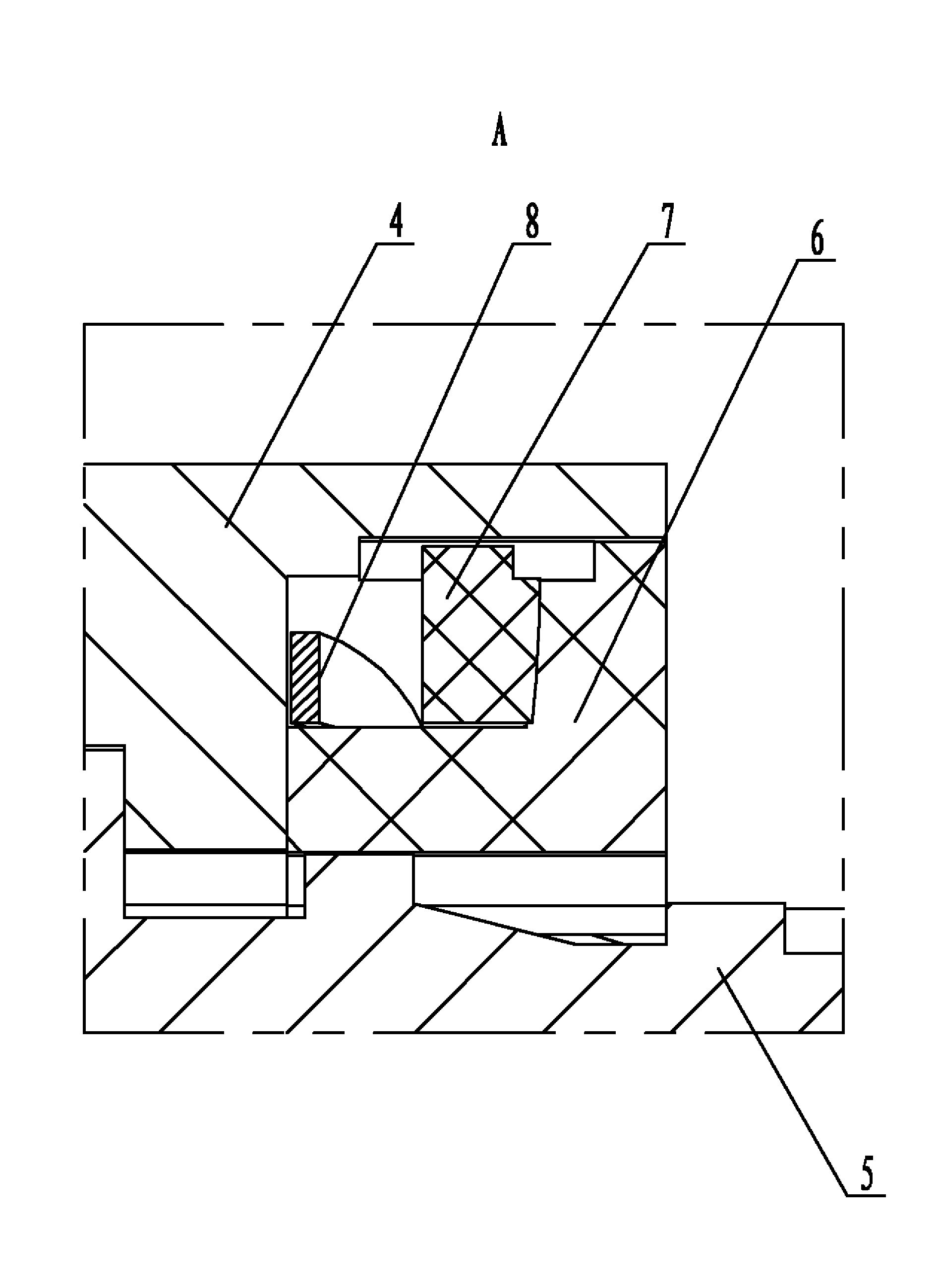

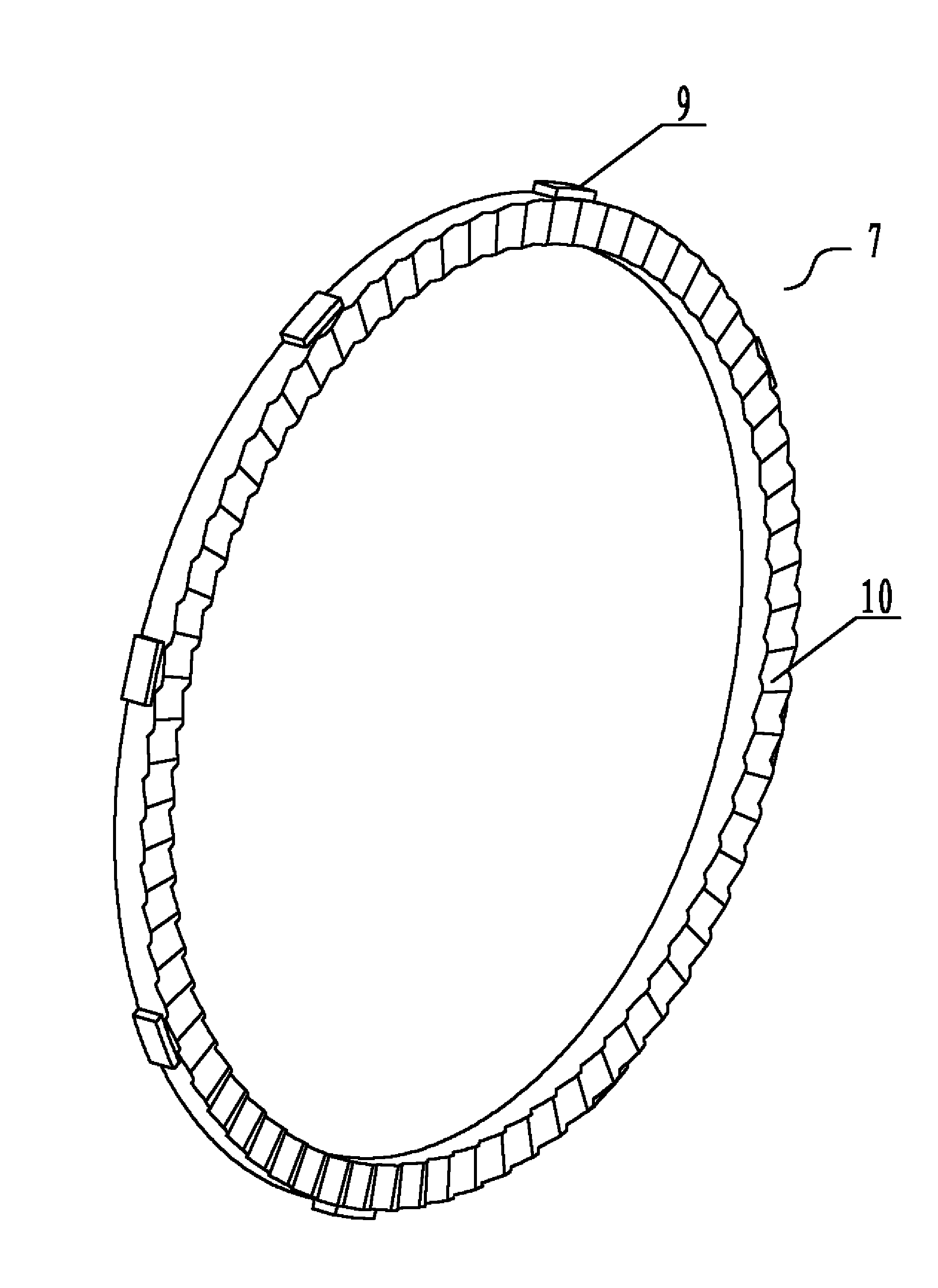

[0030] An embodiment of a connector assembly with a connected feel in place, in Figure 5~14 Among them, it includes a plug and a socket that can be mated with each other, and the mating end of the plug and the socket is the front end. The socket includes a socket housing 40 , and socket contacts are fixedly arranged in the inner hole passing through the front and back of the socket housing 40 through an insulating member. The front section of the outer peripheral surface of the socket housing 40 has external threads. The plug includes a plug housing 15 , the front portion of the plug housing 15 is rotatably fitted with an inner connection nut 21 , and the front section of the inner hole of the inner connection nut 21 has an inner thread that is screwed tightly with the outer thread of the front end of the socket housing 40 . A threaded anti-loosening structure is provided between the inner connection nut 21 and the plug housing 15. The threaded anti-loosening structure includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com