Plant greenhouse

A technology for greenhouses and plants, applied in the field of greenhouses for plants, can solve the problems of complex structure, no adjustment effect, uneven humidity of wet curtains, etc., and achieve a good effect of dimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

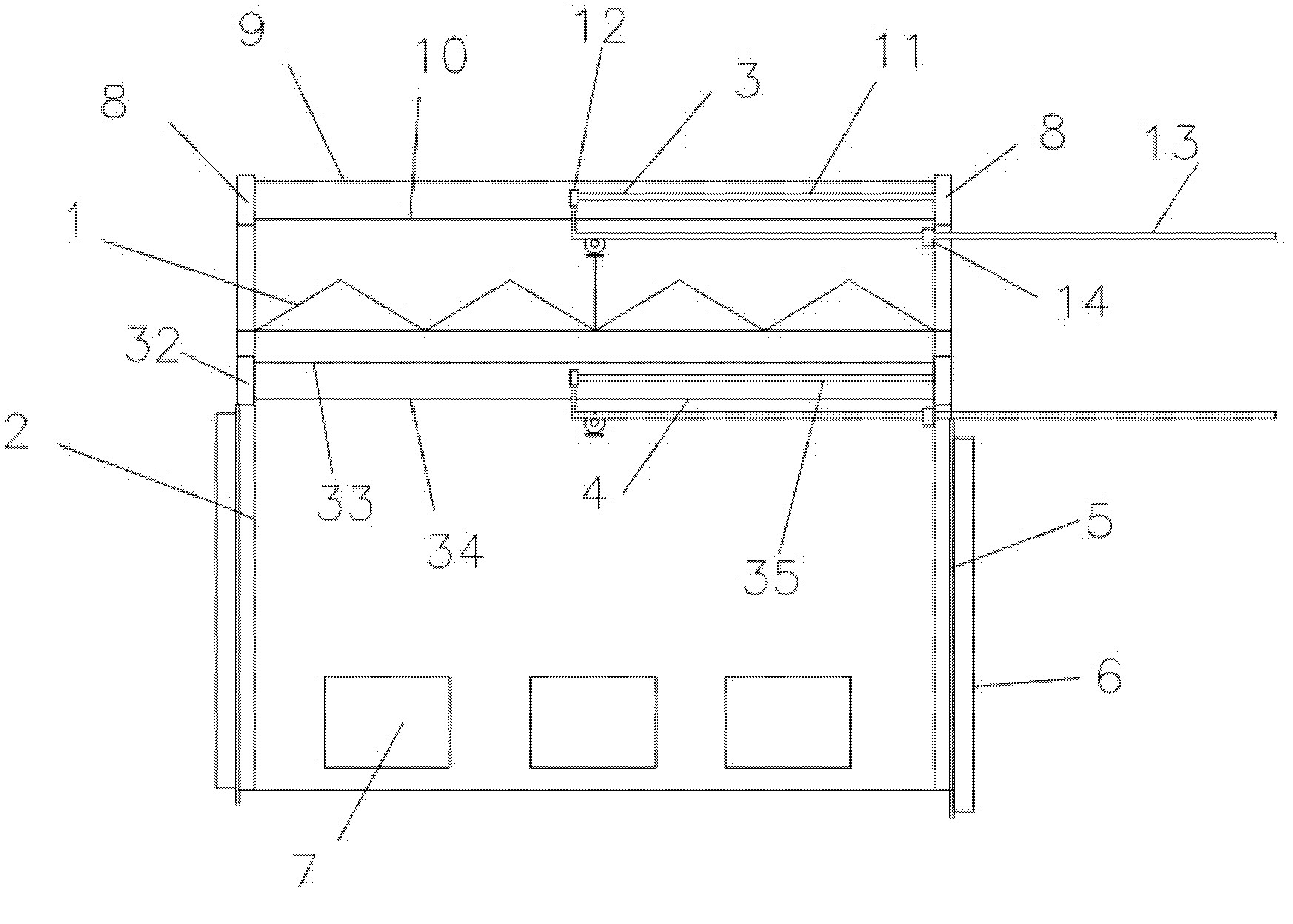

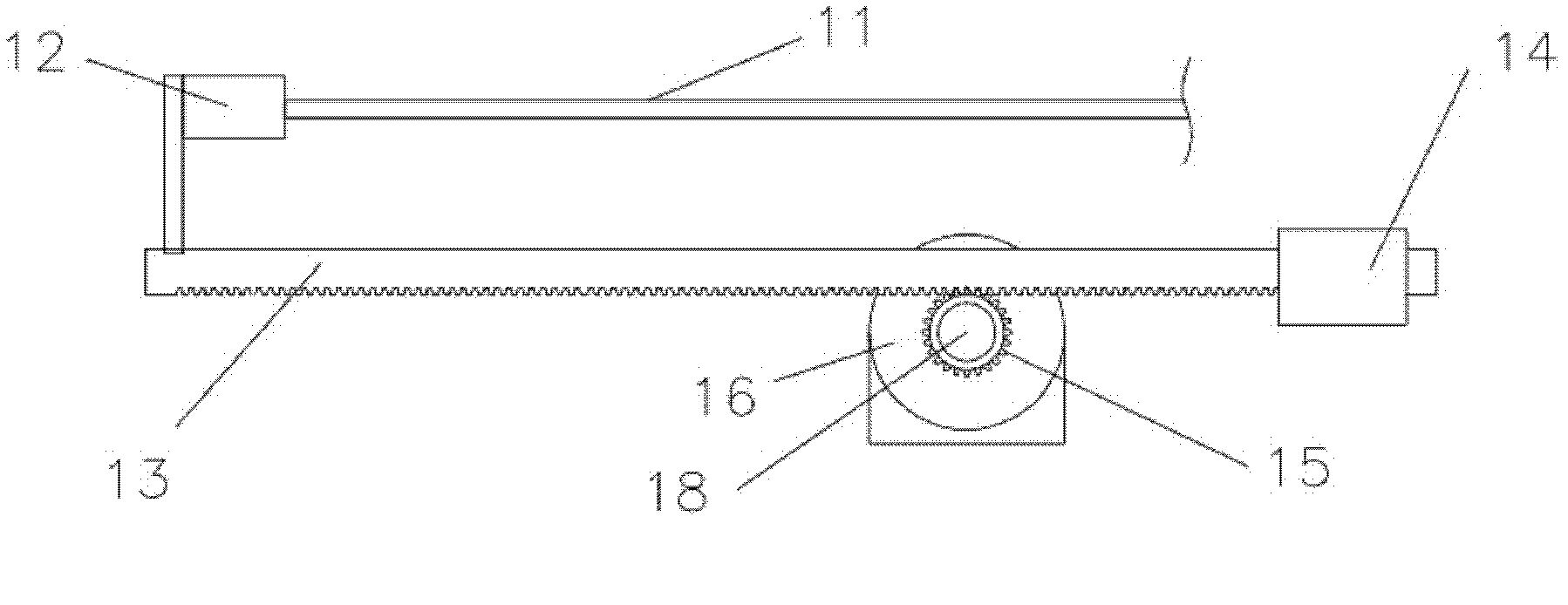

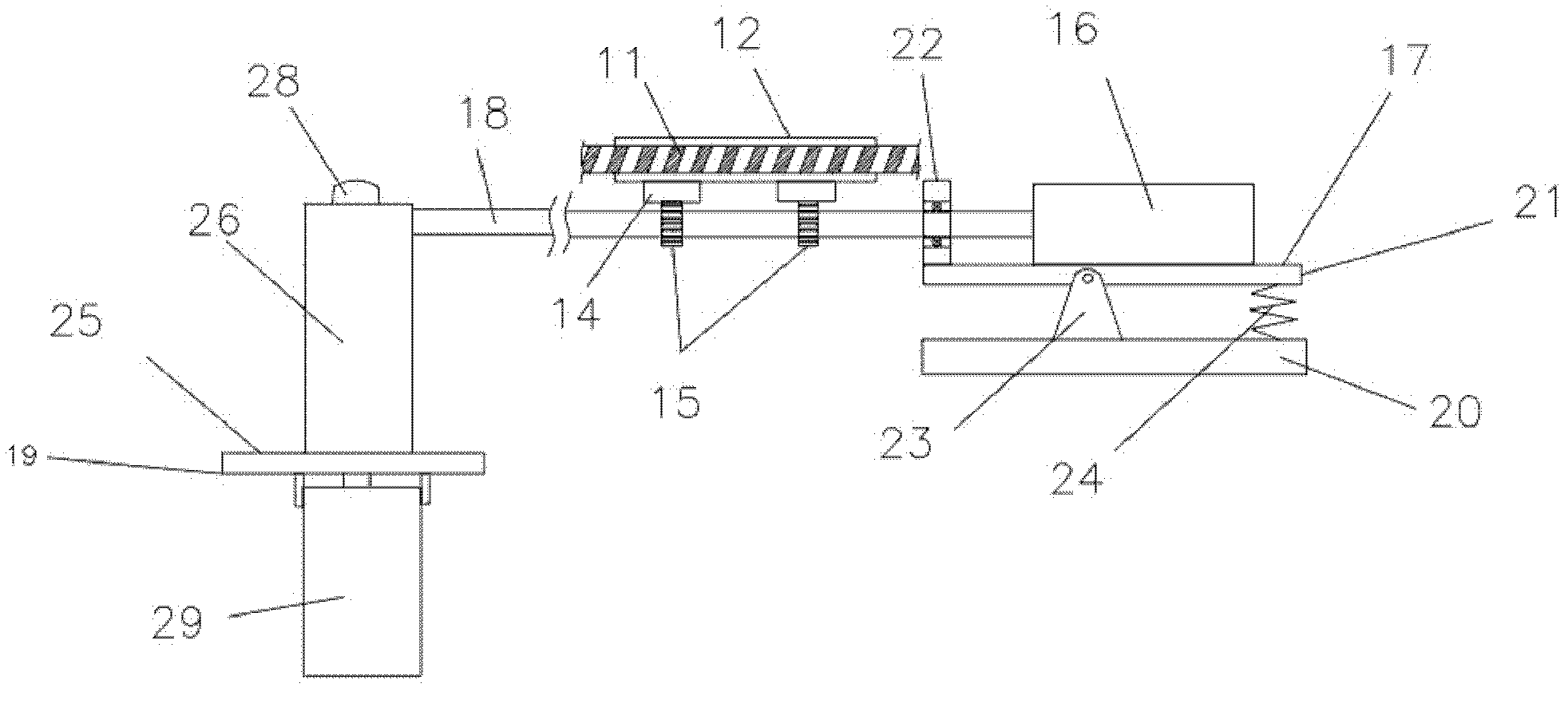

[0067] Such as figure 1 As shown, the plant greenhouse described in this embodiment mainly includes a greenhouse roof, a greenhouse side wall, an external net device, an internal net device, a wet curtain, side windows and a seedbed, and the greenhouse roof is arranged on the greenhouse side wall Above, the external net device is set above the roof of the greenhouse, the internal network device is set under the roof of the greenhouse, the top of the cooling curtain is fixed on the side wall of the greenhouse, the side window is set on the outside of the cooling curtain, and the seedbed is set under the roof of the greenhouse ,Such as figure 2 , 3 , it is characterized in that: described outer net device is mainly composed of upper stretching beam, upper lamination line, upper supporting film line, outer net, upper driving net block, upper rack bar with rack on the bottom surface, upper rack Composed of rod base, upper gear, external grid motor, upper motor base, upper rotat...

Embodiment 2

[0085] Such as Figure 7 ,8 As shown, the plant greenhouse described in this embodiment is different from Embodiment 1 in that the internal network device is mainly composed of a pull-down mesh beam, a lower pressure film line, a lower support film line, an internal network, a lower driving network block, Rolling net rod, net rolling bearing, servo net rolling motor, lower rack bar with rack on the bottom surface, lower rack bar seat, lower gear, inner net motor, lower rotating shaft and lower rotating shaft seat;

[0086] Wherein, the described lower drive mesh block, lower rack bar, and lower rack bar seat are made of aluminum alloy; the aluminum alloy has the advantages of firmness, light weight and anticorrosion; Rod, lower rack rod seat can also be replaced by stainless steel or copper or hard plastic ;)

[0087] There are two pull-down net beams and they are respectively located on both sides below the roof of the greenhouse;

[0088] The lower pressing film line and t...

Embodiment 3

[0097] Such as Figure 9 As shown, the plant greenhouse described in this embodiment is different from Embodiment 2 in that: the structure of the upper driving net block and the lower driving net block are the same and both include the net driving block body. In the longitudinal section, the net driving block The upper part of the body is provided with a first narrow slot opening upwards, the lower part is provided with a second narrow slot opening downwards, the side is provided with a third narrow slot opening to the side, and the other side is provided with a connecting net. A trumpet-mouth groove with a large inside and a small outside, wherein the narrow-mouth groove is a groove structure with a large internal space and a small notch;

[0098] Bolts and gaskets are arranged in the first narrow groove, the threaded section of the bolt stretches out of the notch of the first narrow groove, and the gasket restricts the bolt head in the first narrow groove; the gasket There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com