Metering devices for powder dispensers

A technology of metering device and dispenser, applied in powder material distribution, beverage preparation device, movable measuring chamber, etc., can solve problems such as unergonomic, inability to obtain final powder dose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

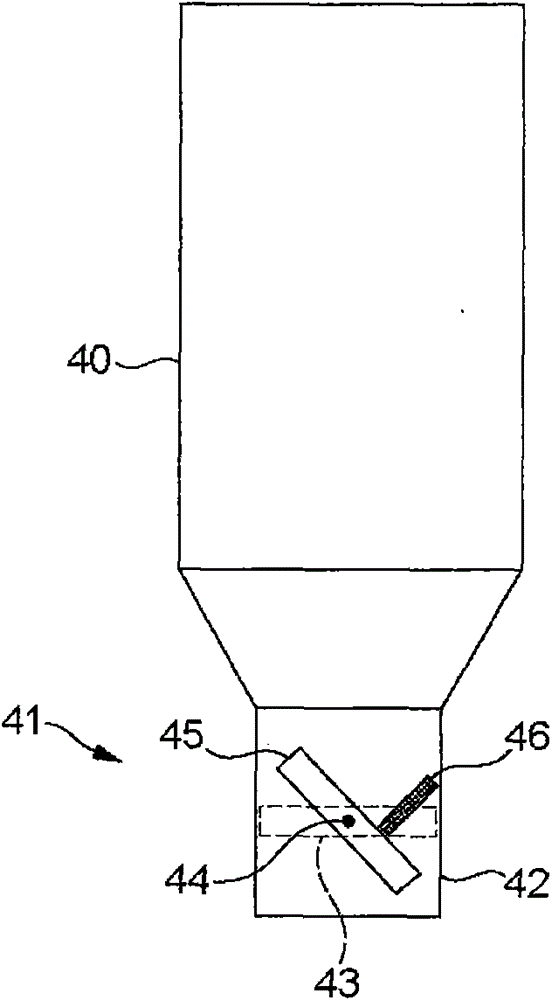

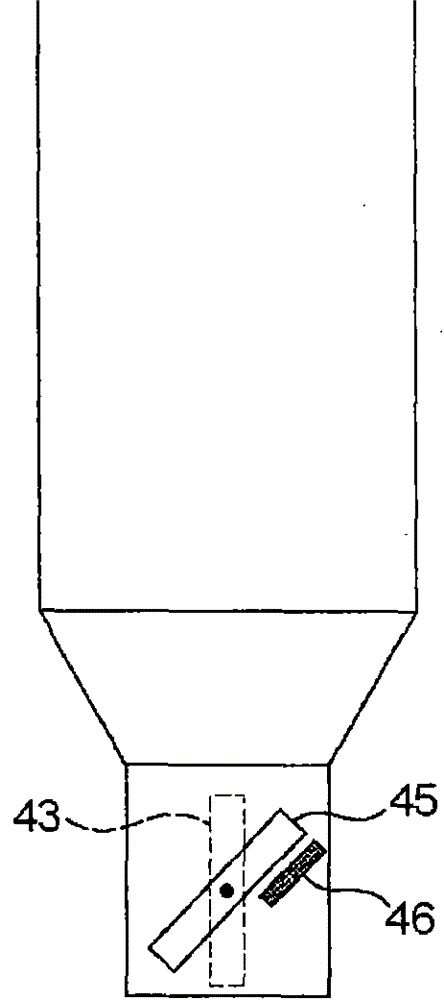

[0033] Figure 1a and 1b The figure shows the way in which a dose of powder is dispensed with a prior art dispenser. The dispenser comprises a tank 40 for storing powder and a metering device 41 . The metering means are present in the tube 42 in which a plate 43 (shown in dashed lines) is arranged in order to close or open the tube section. This plate 43 is fixed on a shaft 44 coupled to a manual actuator 45 . When the metering device is not working, the actuator is in Figure 1a The stationary state shown does have the plate 43 oriented horizontally. Thus no powder is dosed. When it is desired to deliver a dose of powder, the actuator is turned clockwise through a 90° angle so that the plate is vertical and the powder can flow through the tube 42 . A stop member 46 is provided so that the actuator does not rotate more than 90°.

[0034] This allocator has some flaws:

[0035] - To dispense large quantities of powder, the operator using the dispenser must turn the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com