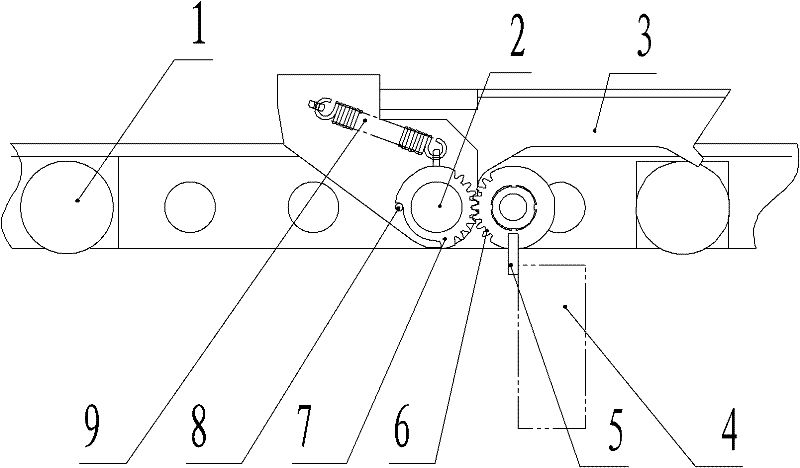

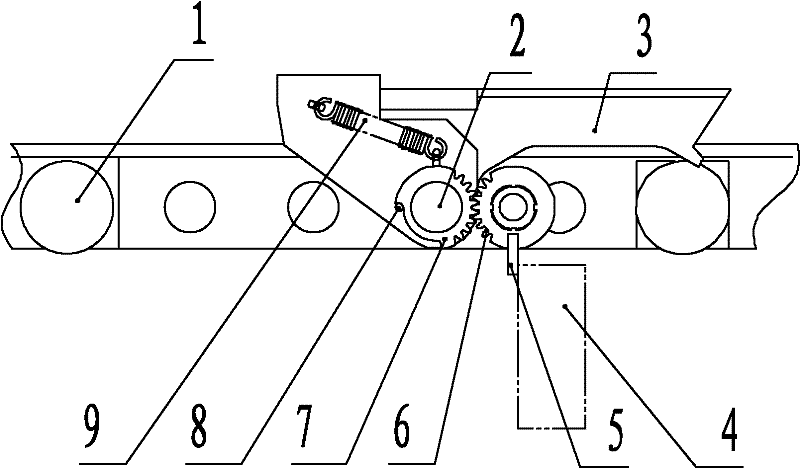

Cart pushing claw device

A pusher and push claw technology, which is applied to railway vehicle traction devices, transportation and packaging, railway car body components, etc., can solve problems such as potential safety hazards, damage to the transmission structure of pusher claw devices, and improve reliability. , Simple structure, flexible transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

[0014] As shown in the figure, a push claw device for a cart machine includes a chain plate 1 of a push cart, a push claw 3, a driving gear 6 and a driven gear 7 provided with a bumper 5, and the push claw 3 and the driven gear 7 pass through The hinged shaft 2 is hinged with the chain plate 1 of the pushcart machine, the push claw 3 is provided with a limit pin 8 which limits the one-way rotation of the driven gear 7, the driven gear 7 is provided with a chute for the reverse sliding of the limit pin 8, and the driving gear 6 meshes with the driven gear 7, and the push claw 3 is provided with a tension spring 9 for the reset of the driven gear 7.

[0015] Working principle: The push claw device of the cart machine is moving forward....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com