Defrosting method for air conditioner

A technology of air conditioning and defrosting time, applied in the direction of damage protection, refrigeration safety arrangements, refrigeration components, etc., can solve the problems of poor heating effect, insufficient heat exchanger capacity, and non-energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

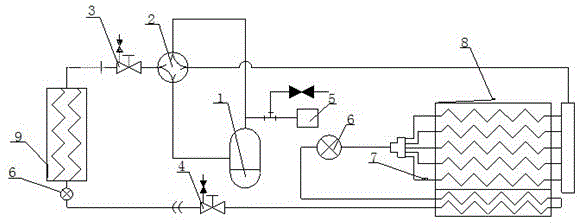

Method used

Image

Examples

Embodiment 1

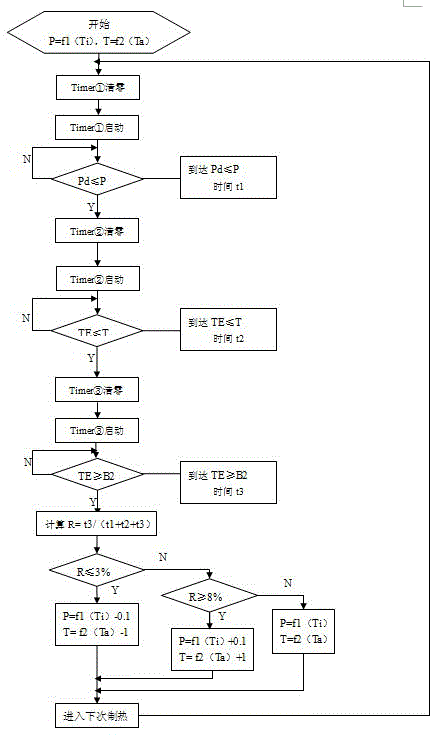

[0026] Control method of the present invention is as follows:

[0027] When the air conditioner unit is turned into the heating state, the four-way valve reversing starts timing, and the high pressure of the system is recorded by the high pressure sensor; when the high pressure Pd≤f1(Ti)MPa, the system has been running for t1 before turning The defrosting temperature sensor is used to record the coil temperature TE of the outdoor heat exchanger. When TE≤f2(Ta)℃, defrosting will start after running time t2. During defrosting, the four-way valve changes direction and starts counting, and turns to the defrosting temperature sensor to record the coil temperature TE of the outdoor heat exchanger. When TE≥12°C, exit defrosting. The running time in defrosting is t3, and turn to the next step. A heating cycle. The ratio of defrosting time to a complete heating cycle time R=t3 / (t1+t2+t3). R≤3%, it can be judged that there is little frost on the outdoor heat exchanger this time, and t...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the A value of this embodiment is set to 2.5%, the B value is set to 7.5%, the set value 1 is set to 0.2 MPa, the set value 2 is set to 2 degrees Celsius, and the B2 setting is 10 degrees Celsius.

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is that the A value of this embodiment is set to 2%, the B value is set to 7%, the set value 1 is set to 0.3 MPa, the set value 2 is set to 3 degrees Celsius, and B2 is set to is 8 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com