Quick-wire power socket

A power socket and fast technology, applied in the directions of circuits, connections, contact parts, etc., can solve the problems of inability to achieve embedded installation, affect the appearance, inconvenient disassembly and assembly, and achieve the effect of simple structure, low cost, and convenient disconnection operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

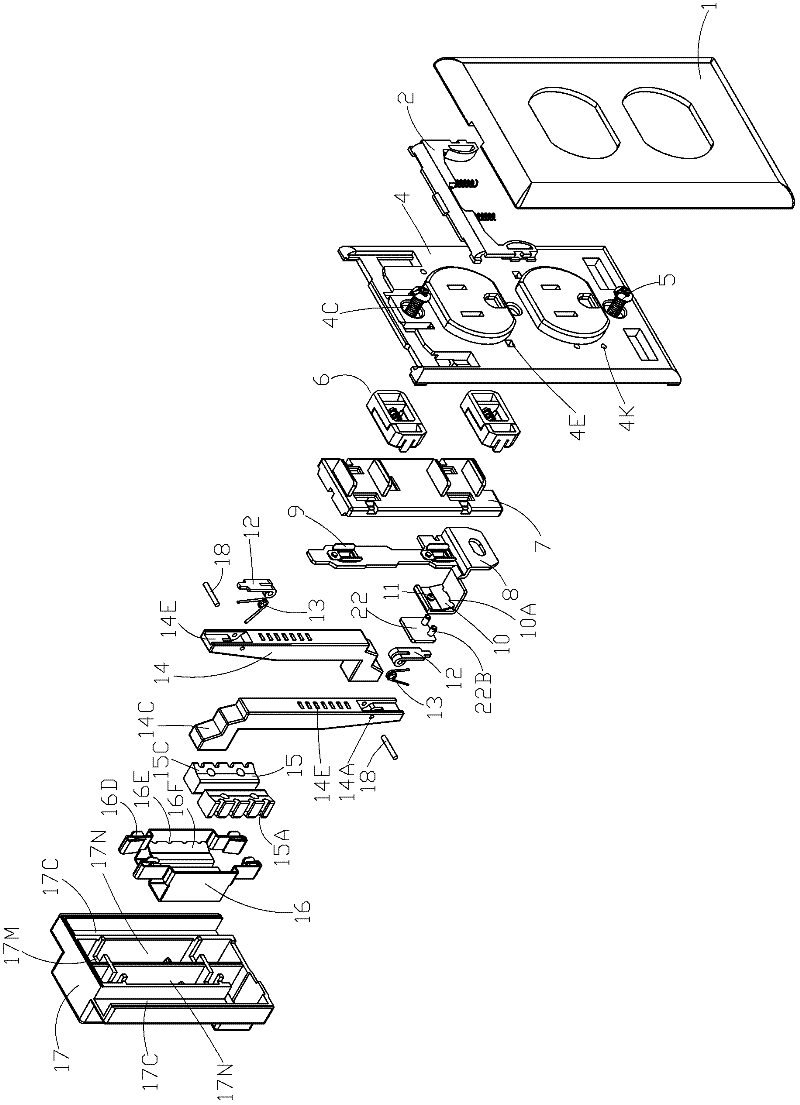

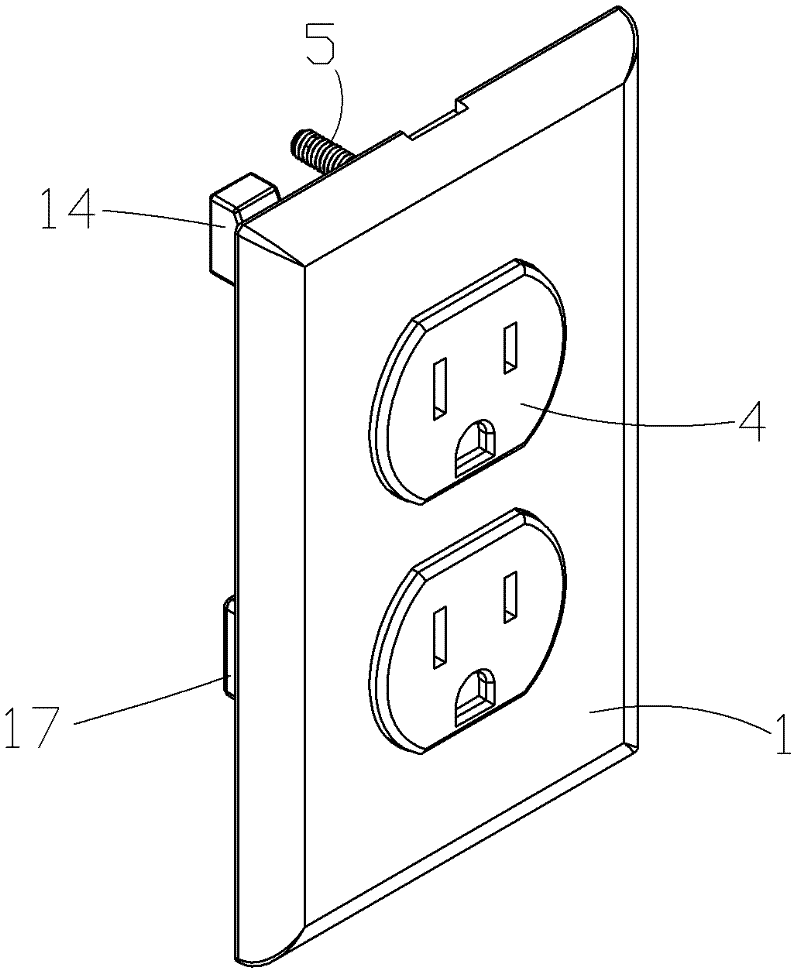

[0049] refer to Figure 1 to Figure 11 , a quick wiring power socket, including a base 17, an upper cover 4 and conductors 16 (including a live conductor and a neutral conductor) with conductive sockets 16D (including live wire sockets and neutral wire sockets), the two conductors are insulated and separated It is arranged in the base 17. In this embodiment, the two conductors are placed in the accommodating groove 17N. The upper cover 4 is provided with jacks corresponding to the positions of the sockets. The live wire conductor and the neutral wire conductor have a side wall and a bottom wall respectively. Both the bottom walls of the two conductors have wiring holes 16B (including wire inlet holes and wire outlet holes), and the bottom wall of the base has corresponding wiring holes 17A (including wire inlet holes and wire outlet holes). The clamping elastic piece 16F with the walls close together, the edge of the clamping elastic piece facing the side wall of the conductor...

Embodiment 2

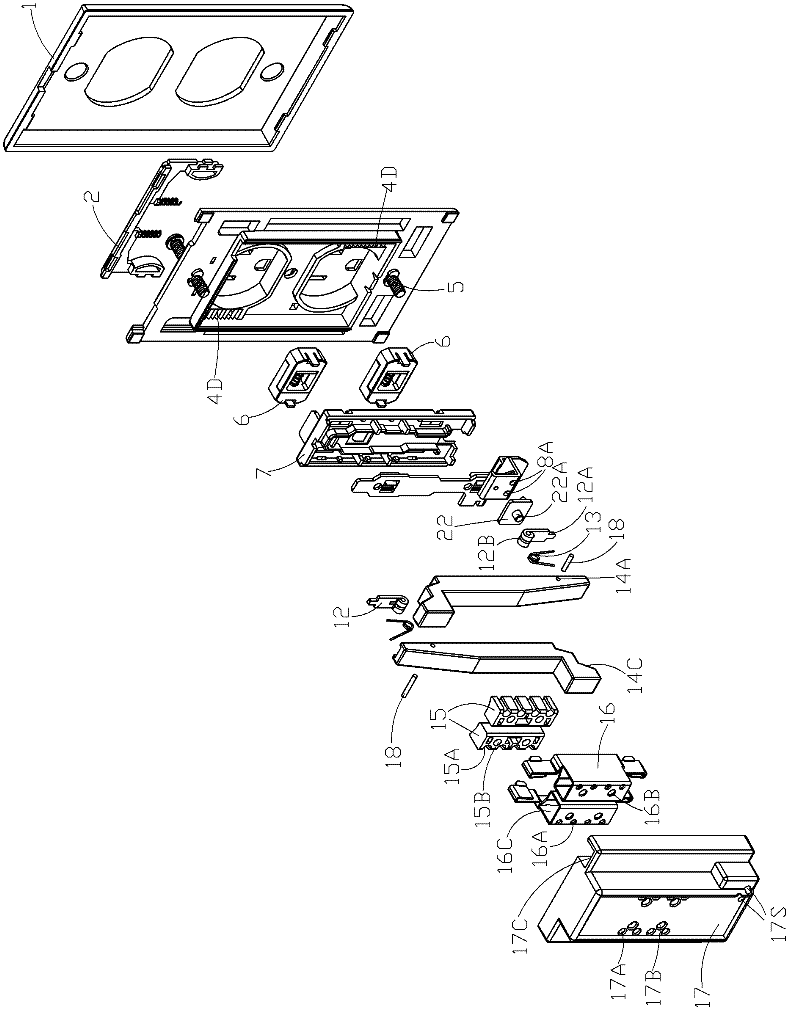

[0062] refer to Figure 12 to Figure 20 , the difference between this embodiment and Embodiment 1 is that the downline insulator 15 is an insulating sheet whose shape is adapted to the bottom wall of the conductor, the insulating sheet is located between the lower surface of the bottom wall of the conductor and the upper surface of the bottom wall of the base, and the bottom wall of the base The bottom wall of the conductor is respectively provided with an off-line through hole corresponding to the position. One side of the insulating sheet has a convex nail 15D corresponding to the off-line through hole on the bottom wall of the base, and the other side has a convex nail corresponding to the off-line through hole on the bottom wall of the conductor. 15C, the clamping elastic piece 16F is in contact with the stud 15C passing through the bottom wall of the conductor so that the stud 15D on the other side of the insulating sheet passes through the bottom wall of the base. Since ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com