Printing ink scraper device of screen printing machine

A screen printing machine and scraper device technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of poor adjustment effect, low efficiency, and long adjustment process cycle, and achieve high adjustment efficiency and adjustment high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

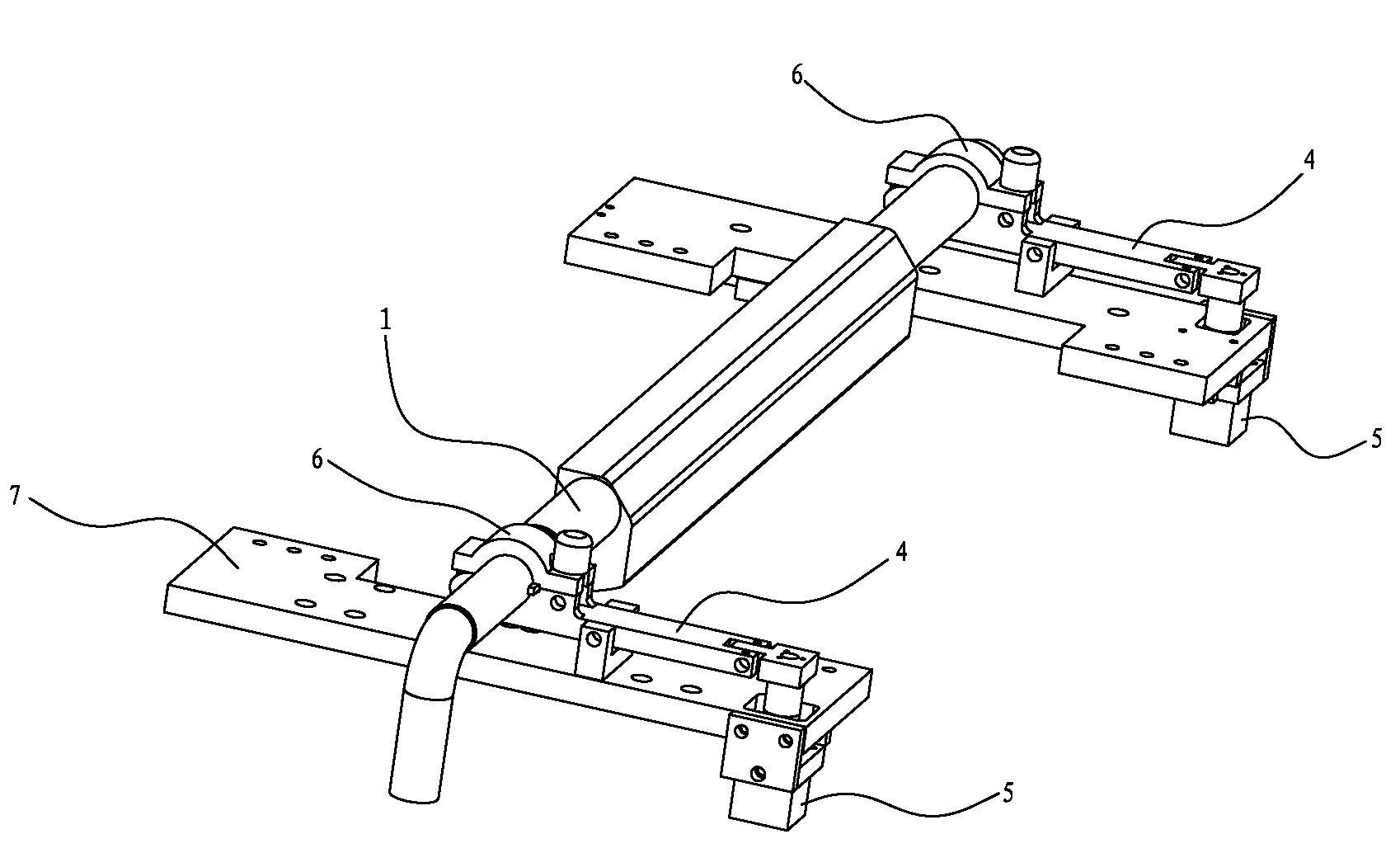

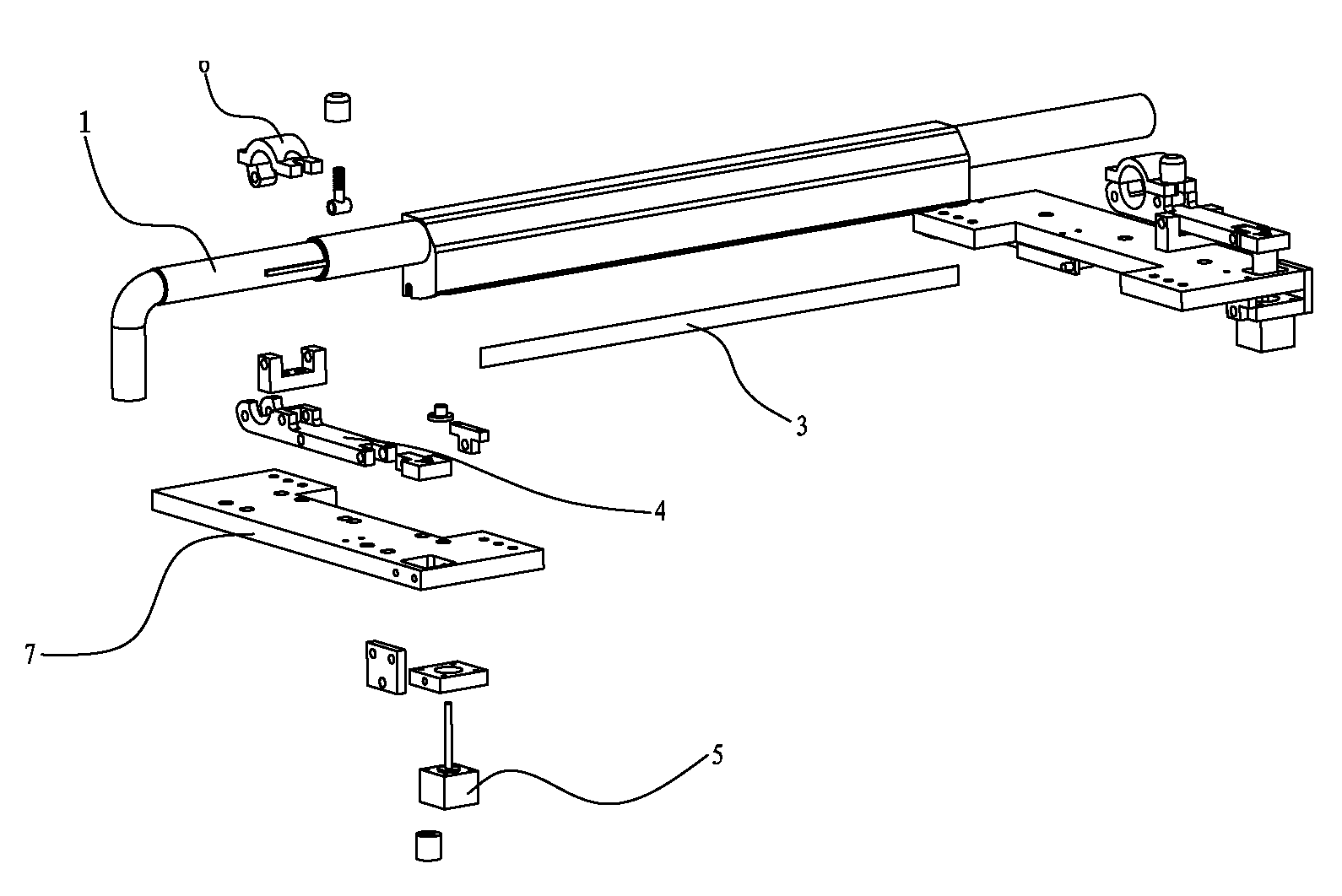

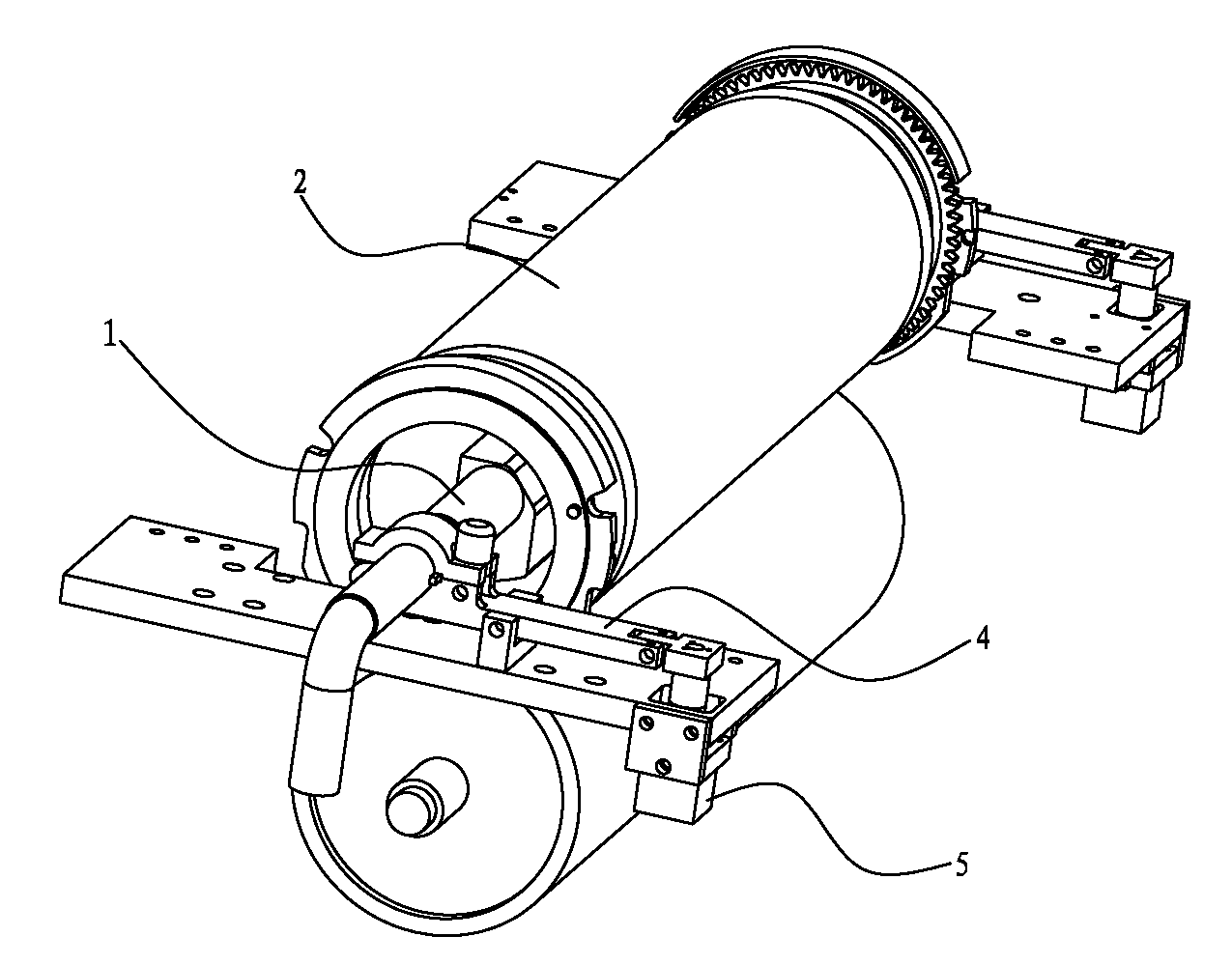

[0023] See figure 1 , figure 2 , image 3 and Figure 4 As shown, an ink scraper device of a screen printing machine includes a scraper shaft 1 extending into the screen printing cylinder 2 of the screen printing machine, and the scraper shaft 1 is pivotally eccentrically arranged on the printing cylinder 2 , the shaft body of the scraper shaft 1 is hollow, the scraper shaft 1 is connected with the ink supply device, the surface of the scraper shaft 1 is provided with an ink outlet, the scraper shaft 1 is equipped with a scraper 3, and the scraper shaft 1 is connected with an adjustment mechanism, the The adjustment mechanism includes a connecting rod 4, one end of the connecting rod 4 is socketed with the scraper shaft 1, the middle part of the connecting rod 4 is hinged to the frame 7 on which the printing cylinder 2 is installed, and the connecting rod 4 is far ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap