Inclined bolster and secondary suspension including the bolster

A technology of support and rigidity, applied in the field of secondary suspension, can solve the problem of inability to improve characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

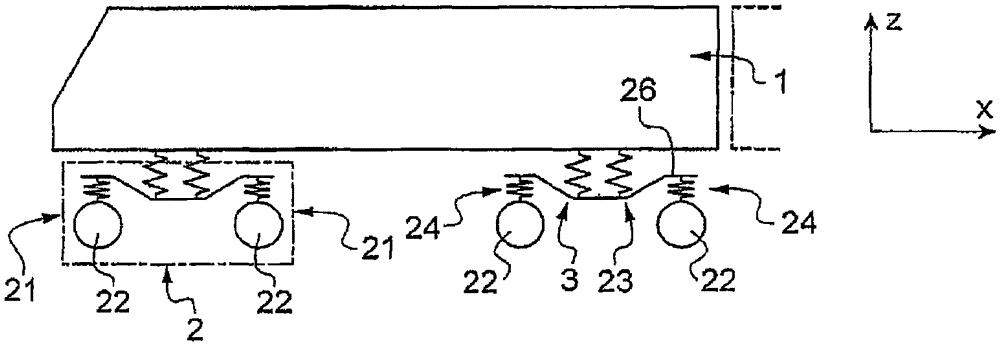

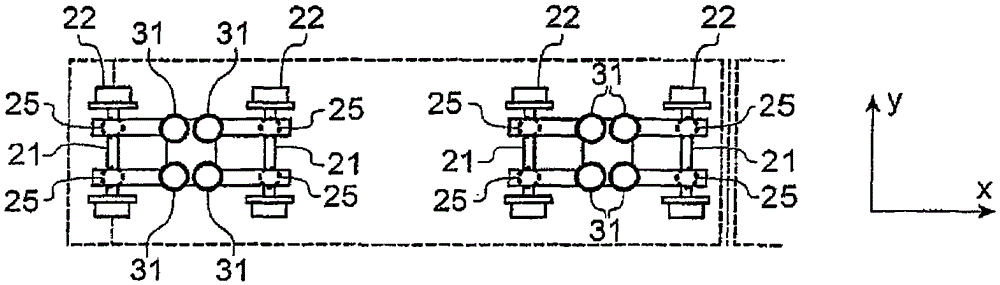

[0037] Figure 1a with 1b Representing a vehicle, the vehicle has a main body 1 and two bogies 2, each bogie includes two axles 21 and four wheels 22, the axles 21 and wheels 22 are suspended on the chassis 23 of the bogie 2 through a primary suspension 24, The primary suspension 24 includes four subassemblies 25 .

[0038] Each bogie 2 is provided with a secondary suspension 3 comprising four subassemblies 31 distributed according to a quadrilateral.

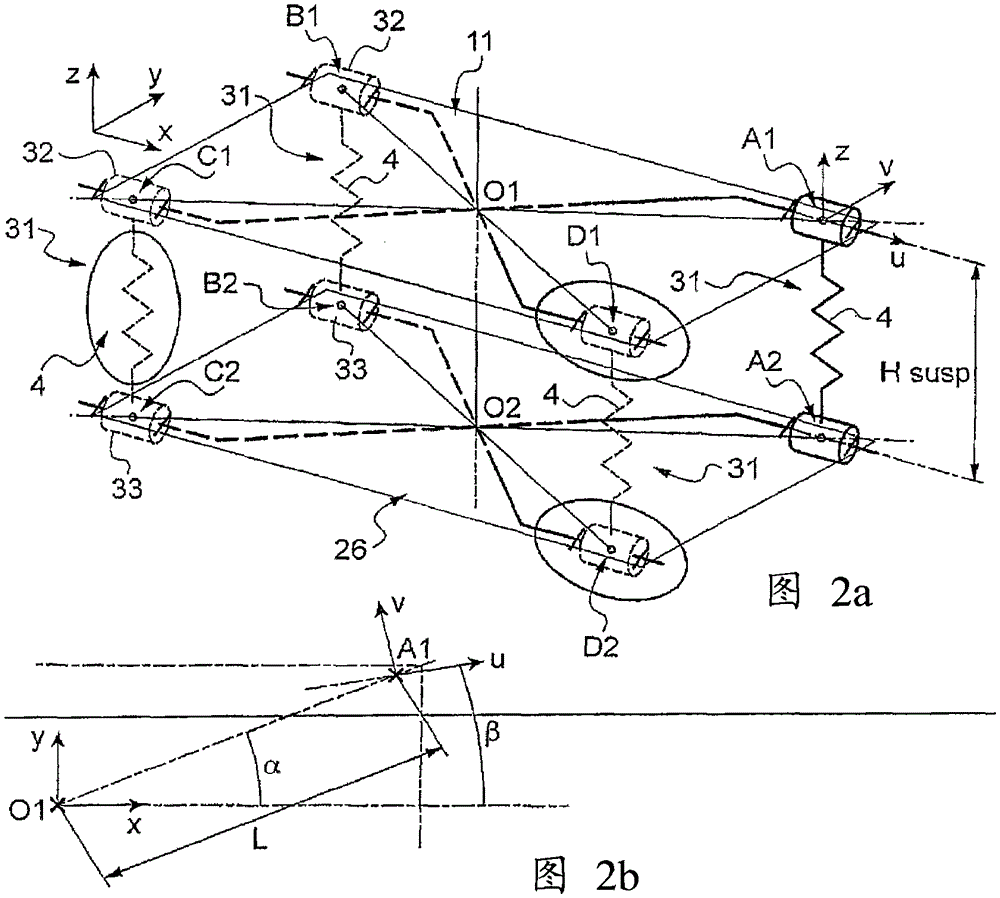

[0039] Figure 2a Four subassemblies 31 are shown, each subassembly 31 comprising two inclined bolsters 32 and 33 between which one or more metal suspension springs 4 are arranged. The upper inclined bolster 32 is integrated with the part 11 for interfacing with the main body 1, the lower inclined bolster 33 is integrated with the part 26 for interacting with the bogie 2, and a series of suspensions are also installed on the bogie 2. Component 25. h susp Specifies the height of the secondary suspension, which includes the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap