Progressive power eyeglass lens and design method thereof

A technology of spectacle lenses and design methods, applied in the directions of glasses/goggles, optics, optical components, etc., can solve problems such as narrowing of the progressive part and near vision area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

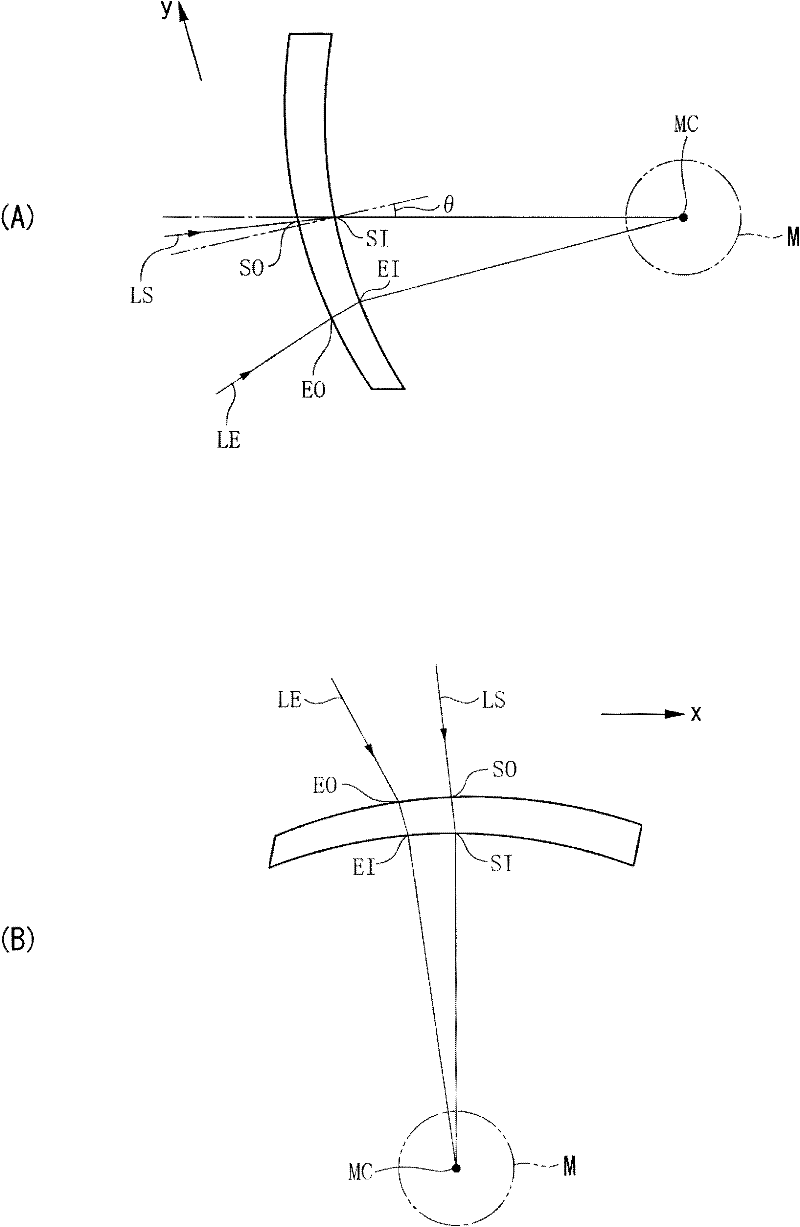

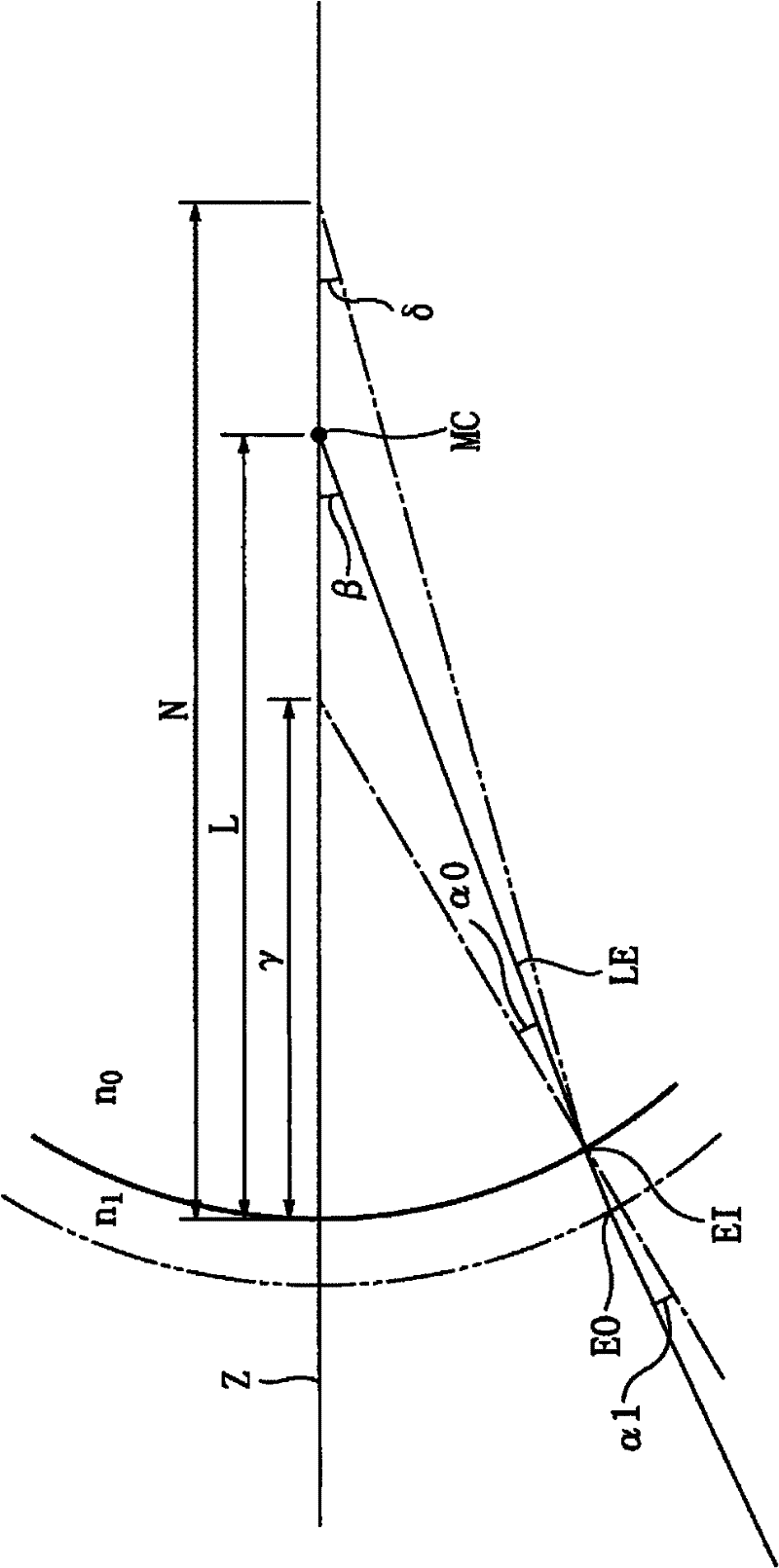

[0105] Assume normal wearing condition (10° forward tilt and 0° bend)

[0106] positive lens

[0107] prescription:

[0108] S=+3.00 ADD=1.75 prism=3.00 prism diopter

[0109] Prism base direction = 0°

[0110] Center thickness: 6.6mm

[0111] Object side faces:

[0112] Far curve = 6 Near curve = 5 Surface addition = -1.00 diopters

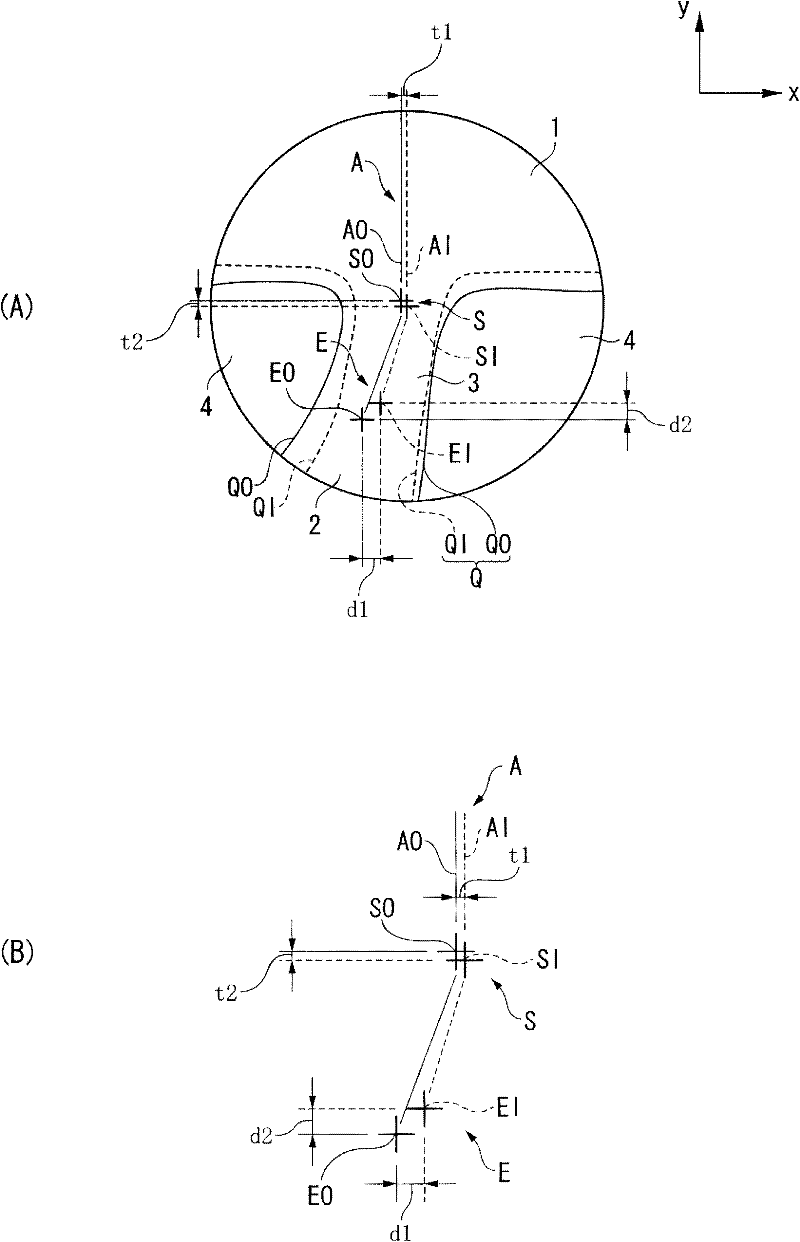

[0113] Progressive start point SO(x, y)=(0.00mm, 0.00mm)

[0114] Progressive end point EO (x, y) = (-2.50mm, -14.00mm)

[0115] The side of the eyeball:

[0116] Far curve = 3 Near curve = 0 Surface addition = +3.00 diopters

[0117] Progressive starting point SI (x, y) = (0.11mm, -0.61mm)

[0118] Progressive end point EI (x, y) = (-2.06mm, -12.67mm)

[0119] In addition, the coordinates of the matching point are set to the origin (0, 0).

[0120] Tables 1 to 3 describe the above setting conditions.

[0121] Design the gradual start point SO and the gradual end point EO of the surface arranged on the object side according to the con...

Embodiment 2

[0125] Assume a wearing state with a forward inclination angle of 20° and a bending angle of 0°

[0126] Positive lens prescription is identical with embodiment 1.

[0127] The setting of the surface on the object side is the same as in Example 1.

[0128] The setting of the surface on the eyeball side is the same as that of the first embodiment except for the coordinates of the gradual start point SI and the gradual end point EI.

[0129] Progressive starting point SI (x, y) = (0.11mm, -1.25mm)

[0130] Progressive end point EI (x, y) = (-2.05mm, -13.27mm)

[0131] Tables 1 to 3 describe the above setting conditions.

[0132] Embodiment 2 is the same as Embodiment 1. Design the gradual start point SO and gradual end point EO of the surface on the object side according to the existing method, and set the gradual start point SI and the gradual end point of the surface on the eyeball side The point EI is offset in xy coordinates with respect to these progressive start point ...

Embodiment 3

[0135] Assume normal wearing condition (10° forward tilt and 0° bend)

[0136] negative lens

[0137] prescription:

[0138] S=-8.50 ADD=2.75

[0139] Center thickness: 1.3mm

[0140] Object side faces:

[0141] Far curve = 1 Near curve = 2.5 Surface addition = +1.50 diopters

[0142] Progressive start point SO(x, y)=(0.00mm, 0.00mm)

[0143] Progressive end point EO (x, y) = (-2.50mm, -14.00mm)

[0144] The side of the eyeball:

[0145] Far curve = 9.5 Near curve = 8 Surface addition = +1.50 diopters

[0146] Progressive starting point SI (x, y) = (0.00mm, -0.15mm)

[0147] Progressive end point EI (x, y) = (-2.35mm, -13.41mm)

[0148] Table 1 and Table 2 describe the above setting conditions.

[0149] Design the gradual start point SO and the gradual end point EO of the surface arranged on the object side according to the conventional method, and set the gradual start point SI and the gradual end point EI of the surface arranged on the eyeball side relative to these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com