Manufacturing method of cotton belt as well as cotton belt and slippers

A production method and cotton technology, applied to shoe uppers, footwear, boot legs, etc., can solve the problems of uneven thickness of cotton belts, long production time, inconvenient production, etc., and achieve simple production methods, high production efficiency, and good appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] as attached figure 1 - attached image 3 Shown, a kind of manufacture method of cotton tape, comprises the following steps:

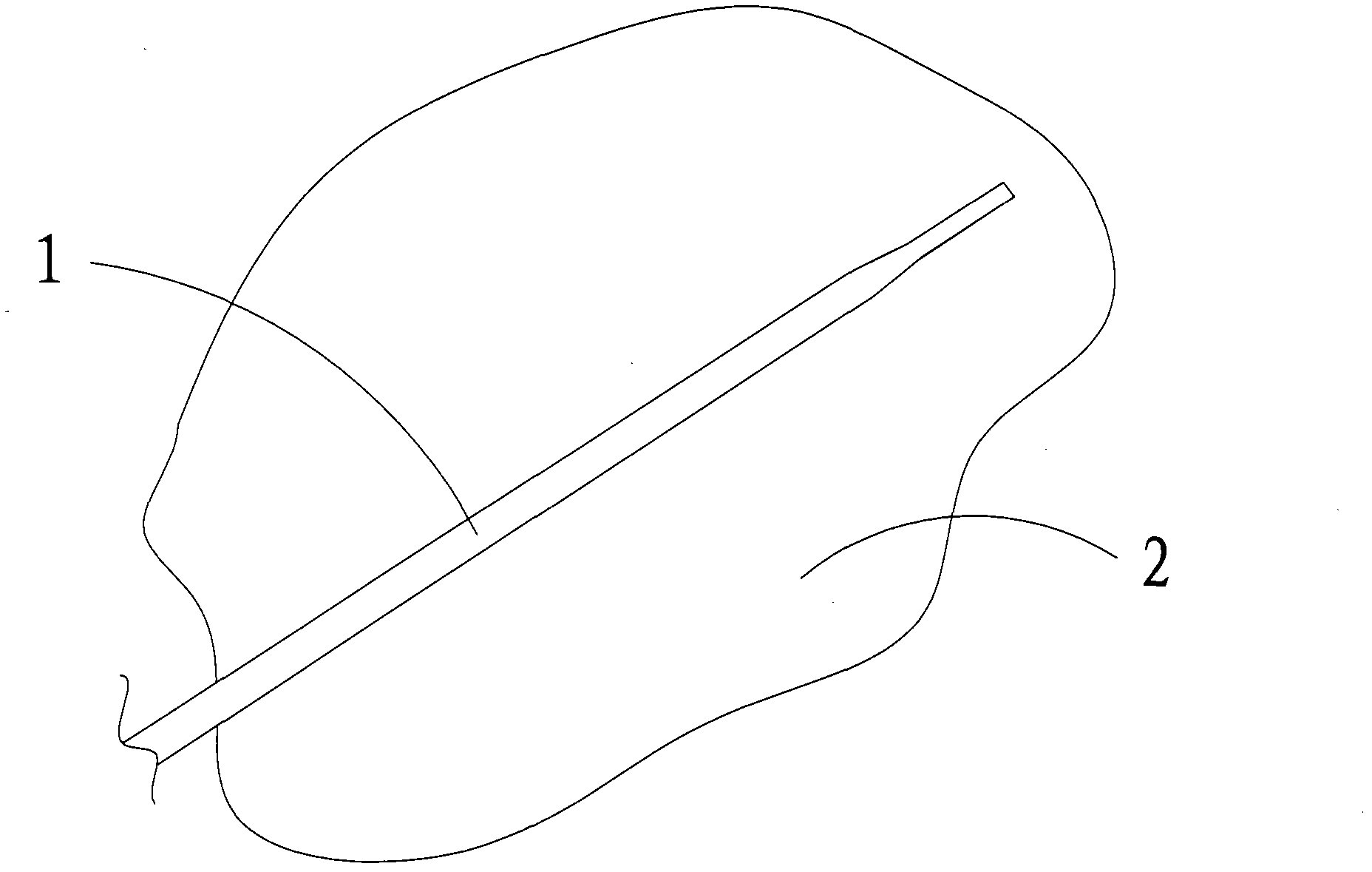

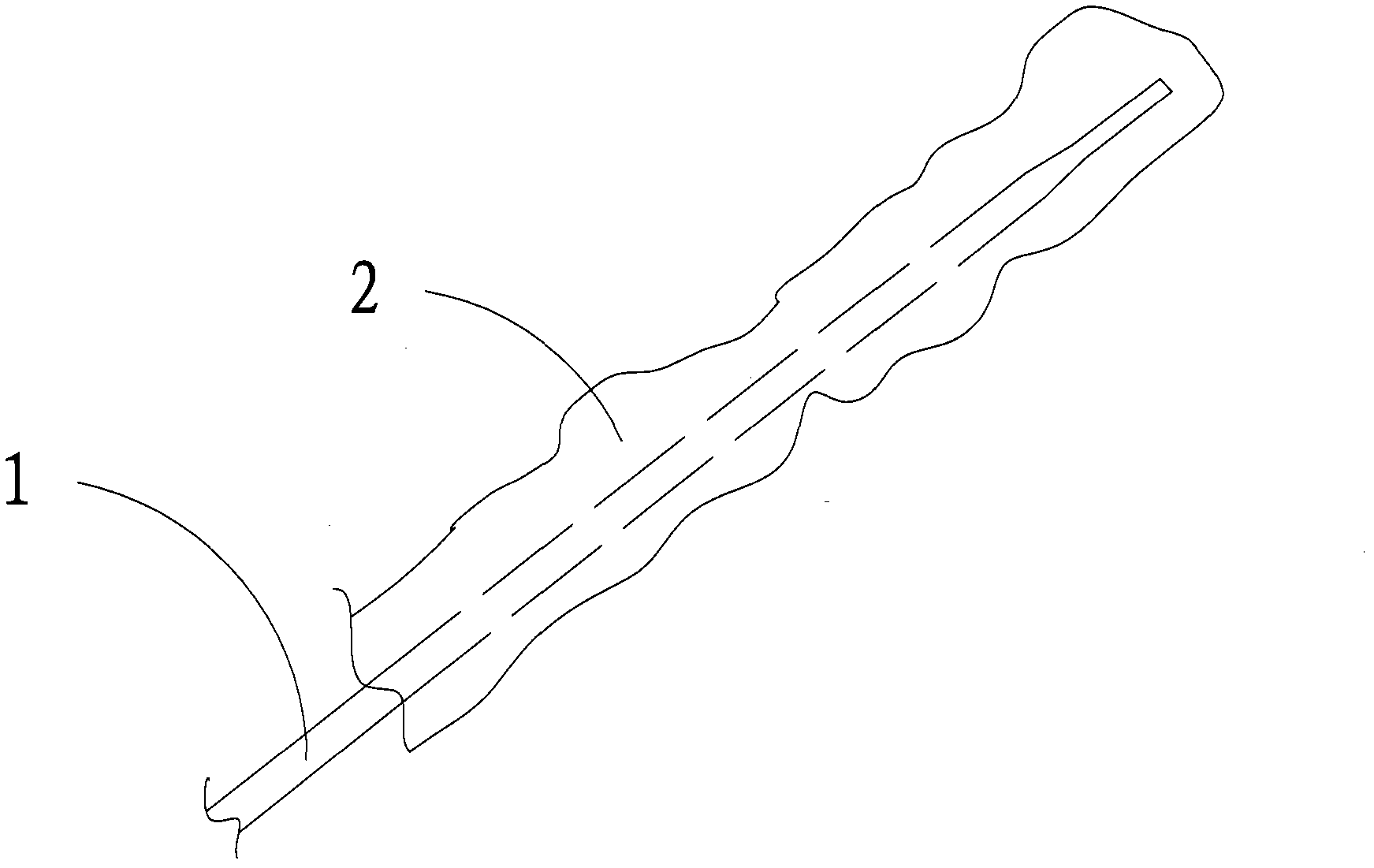

[0023] 1. Prepare a slender rod 1 and cotton 2, and wrap the cotton 2 evenly on the slender rod 1;

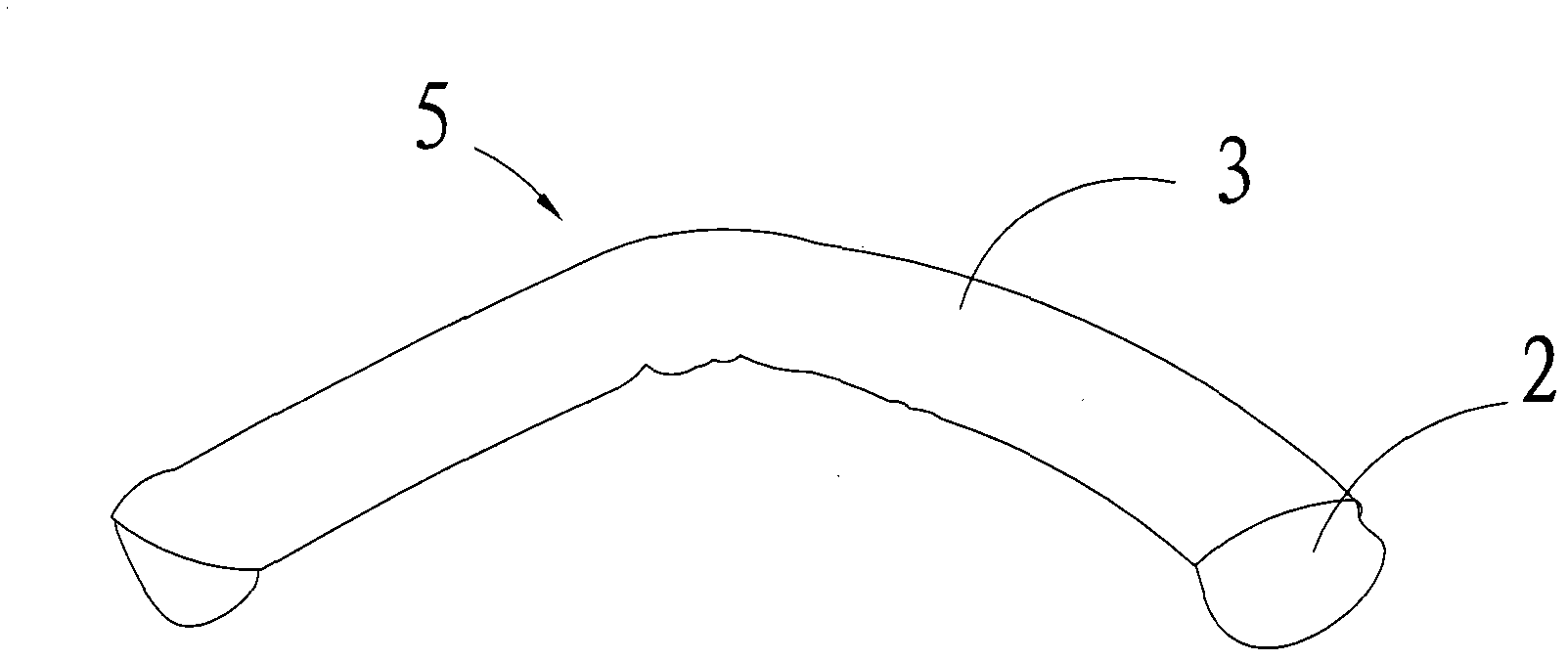

[0024] 2. Prepare a strip-shaped cloth cover 3 with an inner cavity, and insert the slender rod 1 wrapped with cotton 2 into the cloth cover 3;

[0025] 3. Hold the cloth cover 3 inserted with the slender rod 1 wrapped around the cotton 2, pull out the slender rod 1, and leave the cotton 2 in the cloth cover 3 to form the cotton belt 5. The cloth cover 3 is formed by sewing two opposite side portions of the strip of cloth together.

[0026] One end of the elongated rod 1 is pointed. It is convenient to insert into the inner cavity of the cloth cover 3.

[0027] The diameter of the elongated rod 1 is 5 millimeters. The length of the elongated rod 1 is 35 centimeters.

[0028] The diameter of described cloth cover 3 is 3.5 centimetres. The l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap