Automobile rearview mirror face actuator

An automotive rear-view mirror and driver technology, which is applied to vehicle components, optical observation devices, transportation and packaging, etc., can solve the problems of unsmooth manual adjustment, small adjustment angle of the floating plate, and small movement space, and achieve smooth manual adjustment. , The effect of small vibration space and increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

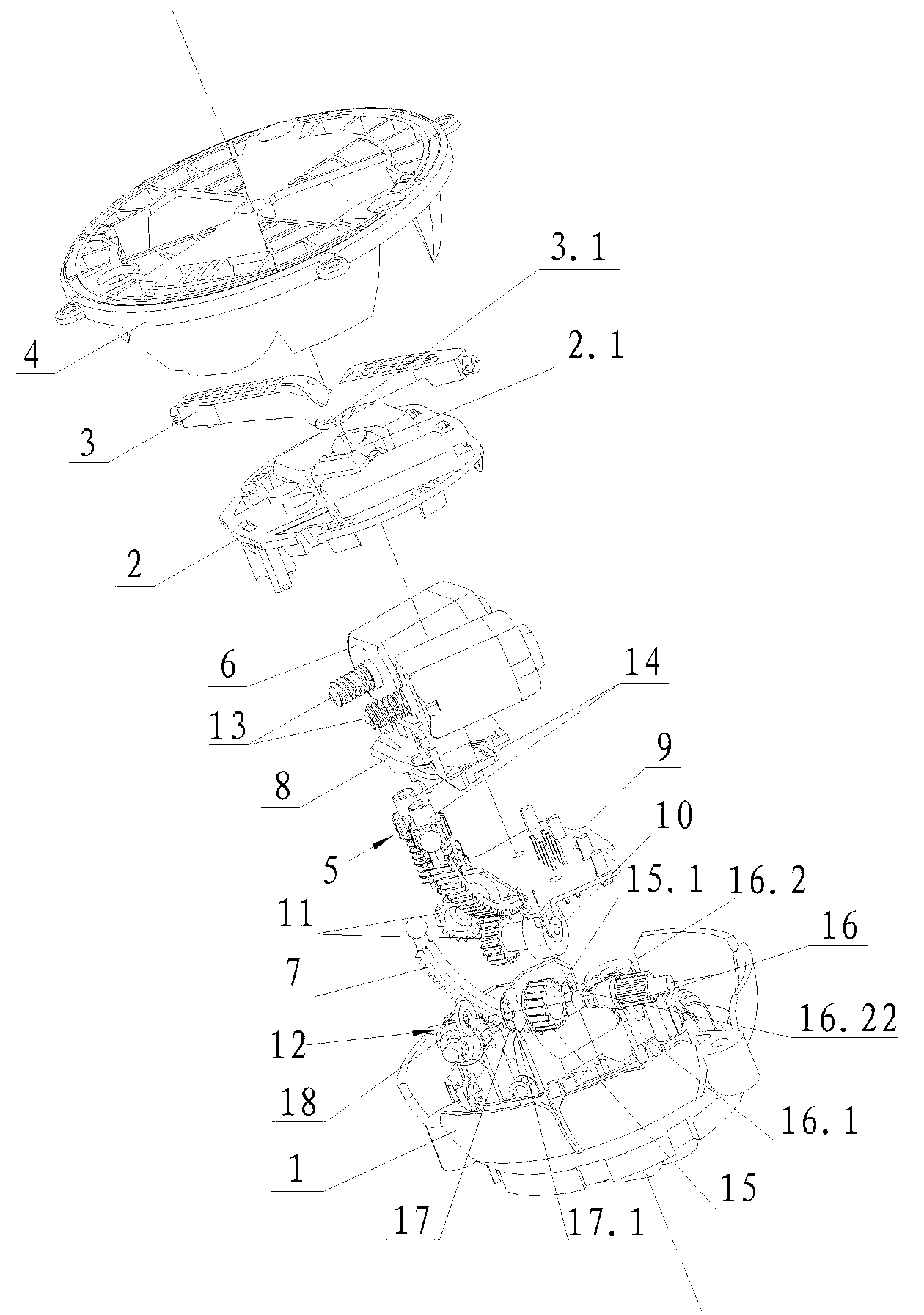

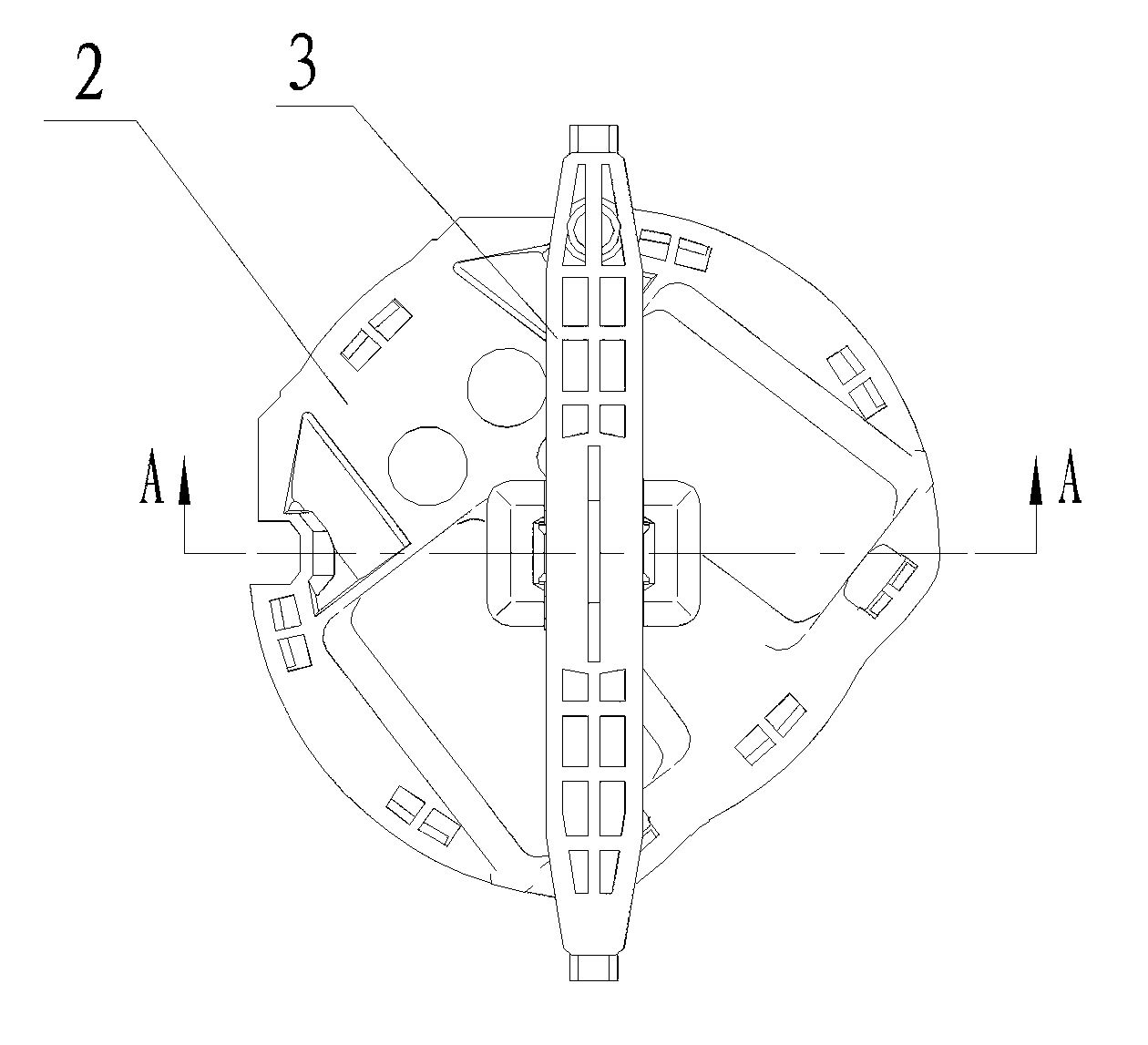

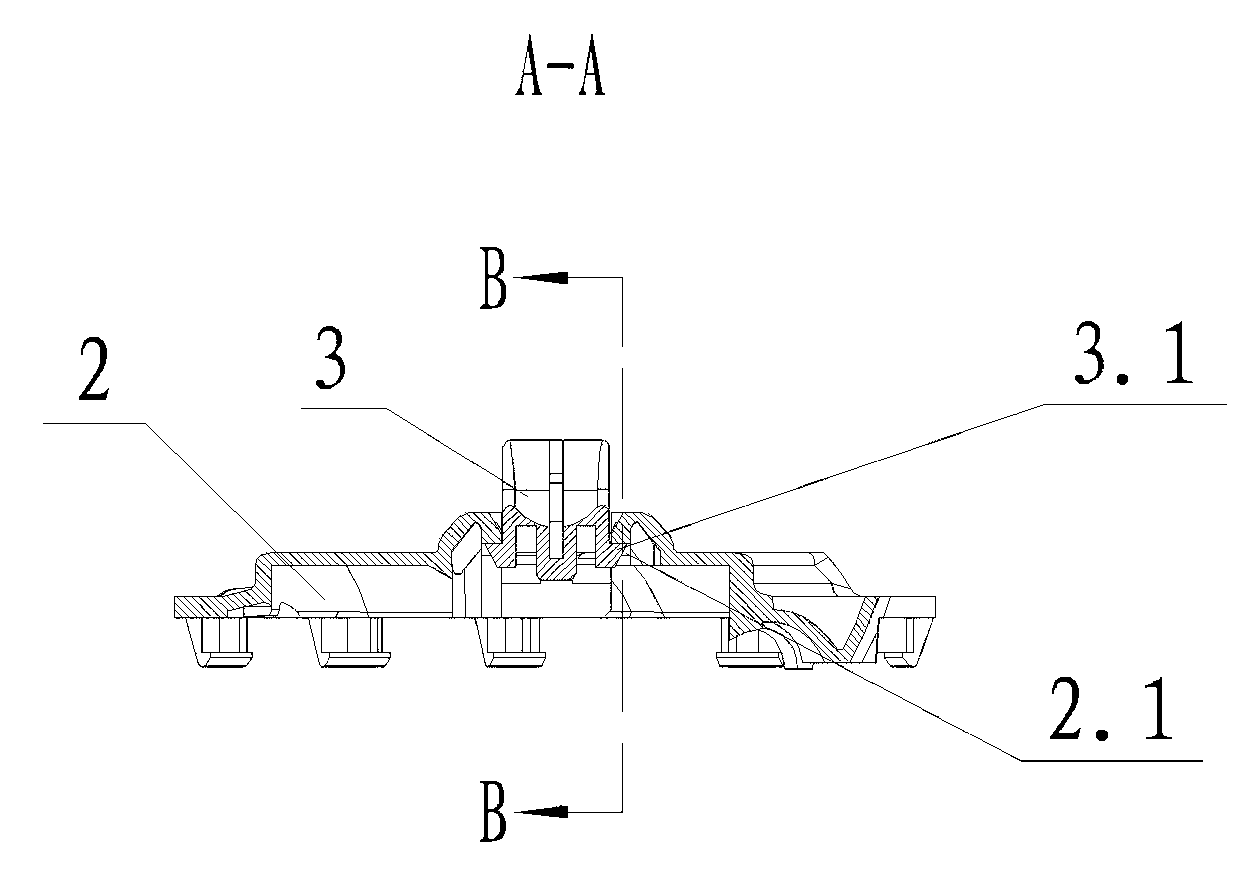

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 Shown a kind of automobile rearview mirror mirror driver, it comprises base 1, loam cake 2, floating bar 3, floating plate 4, transmission device 5 and two motors 6 that are connected with transmission device 5 and arc rack 7, so The base 1 is slidingly connected with the floating plate 4, the upper cover 2 is located between the base 1 and the floating plate 2 and is fixedly connected with the base 1, the transmission device 5, the motor 6 and the arc rack 7 are all located Between the upper cover 2 and the base 1, the floating rod 3 is located between the floating plate 4 and the upper cover 2, and the two ends of the floating rod 3 are rotatably connected with the floating plate 4, specifically the two ends of the floating rod 3 Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com