Ceramic embedded type cylindrical traveling wave ultrasonic motor vibrator pretightened by using wedge blocks

An ultrasonic motor, embedded technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of low electromechanical coupling efficiency and difficulty in improving mechanical output capability. , to achieve the effects of high electromechanical coupling efficiency, improved mechanical output characteristics, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

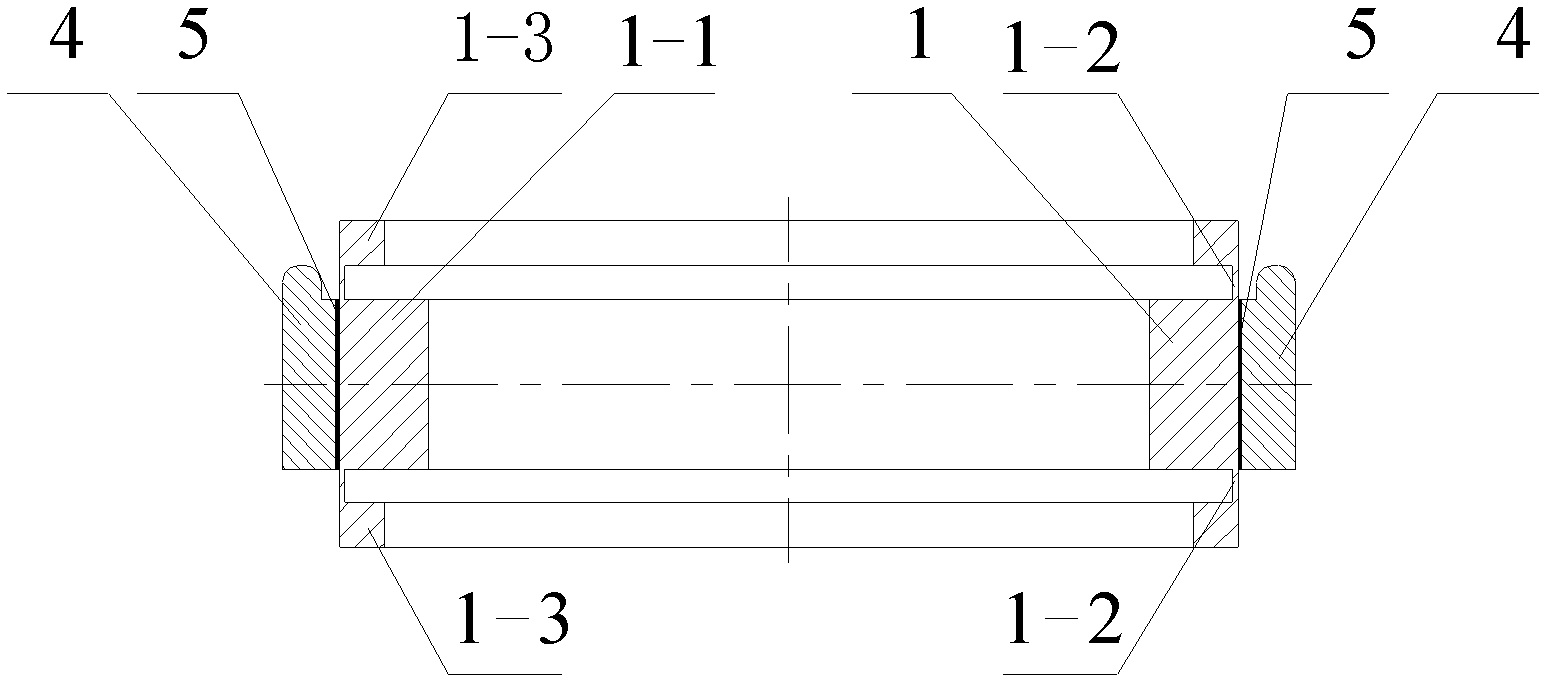

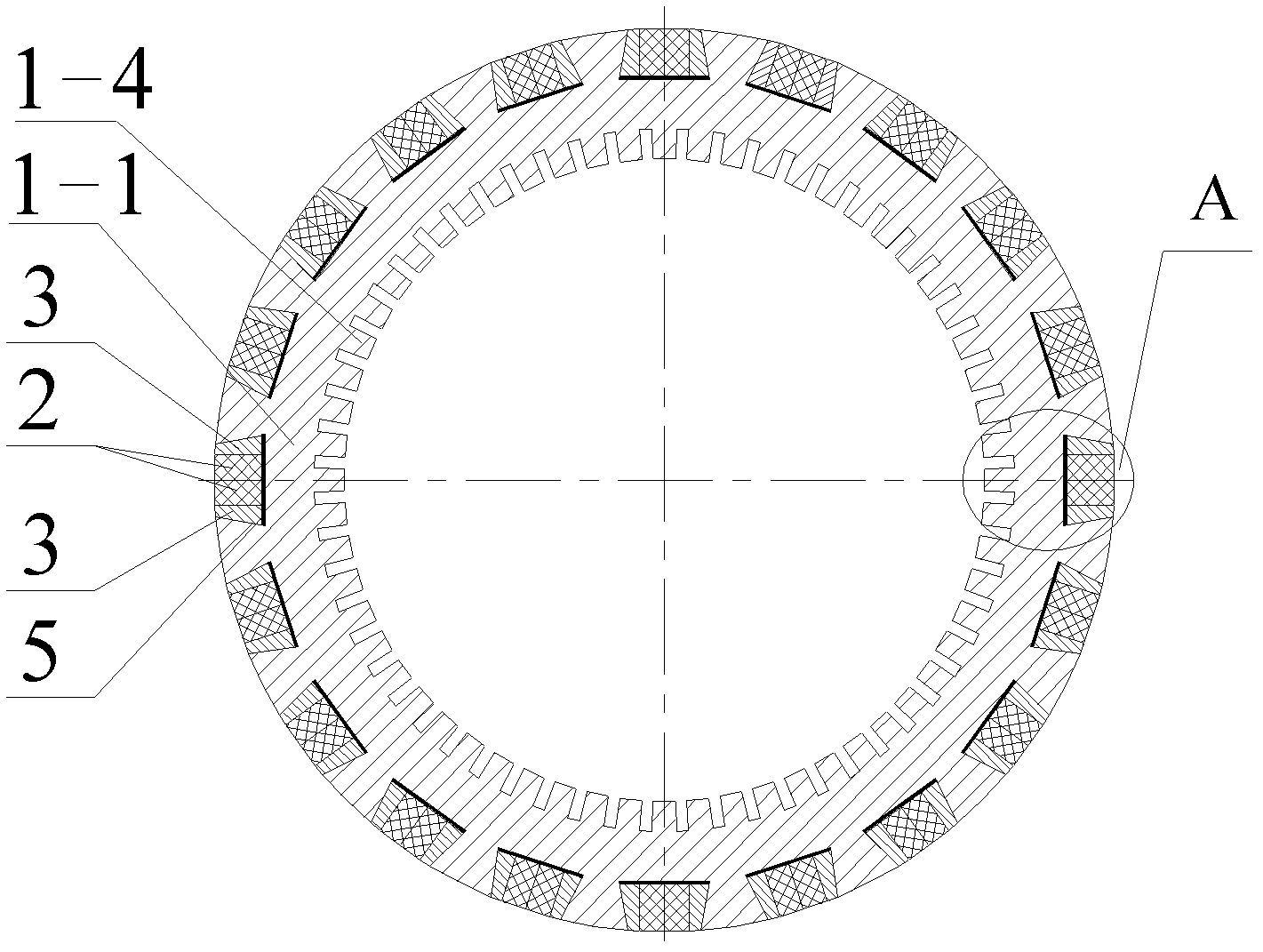

[0019] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment. The ceramic embedded cylindrical traveling wave ultrasonic motor vibrator using wedge-shaped preload in this embodiment includes metal substrates 1, 4n piezoelectric ceramic sheet pairs 2, 8n wedge blocks 3, 4n An electrode piece 4 and 4n insulating spacers 5, n is a natural number greater than or equal to three;

[0020] The metal base 1 is composed of a cylinder 1-1, two thin-walled rings 1-2 and two flanges 1-3, and both axial ends of the cylinder 1-1 are provided with thin-walled rings 1-2 and flanges 1-3. 3. The thin-walled ring 1-2 is located between the cylinder 1-1 and the flange 1-3, and the central axes of the cylinder 1-1, the thin-walled ring 1-2 and the flange 1-3 coincide,

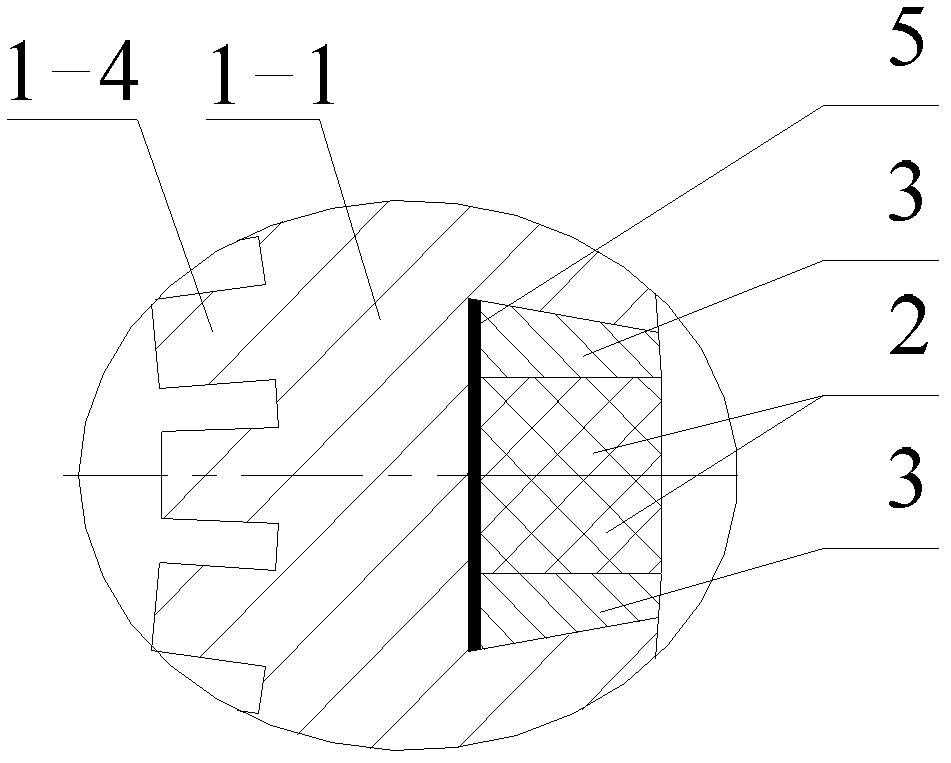

[0021] The inner surface of the cylinder 1-1 is uniformly processed with continuous comb-shaped driving teeth 1-4 along the circumferential direction, and the outer surface of t...

specific Embodiment approach 2

[0028] Specific implementation mode two: the following combination figure 1 This embodiment is described. This embodiment is a further description of Embodiment 1. The cylinder 1-1, the two thin-walled rings 1-2 and the two flanges 1-3 are integrated.

specific Embodiment approach 3

[0029] Specific implementation mode three: the following combination figure 2 and image 3 This embodiment is described. This embodiment is a further description of Embodiment 1 or 2. The inclination of the side wall surface of the channel with an isosceles trapezoidal cross section is the same as the inclination of the slope of the wedge block 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com