Active safe mine vehicle braking device

A safe braking and active technology, which is applied in the direction of railway braking systems, braking components interacting with rails, transportation and packaging, etc., can solve the problems of large destructive equipment, complex structure and difficult implementation, and achieve The effect of strong adaptability, scientific and reliable control, and simple and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and illustrations.

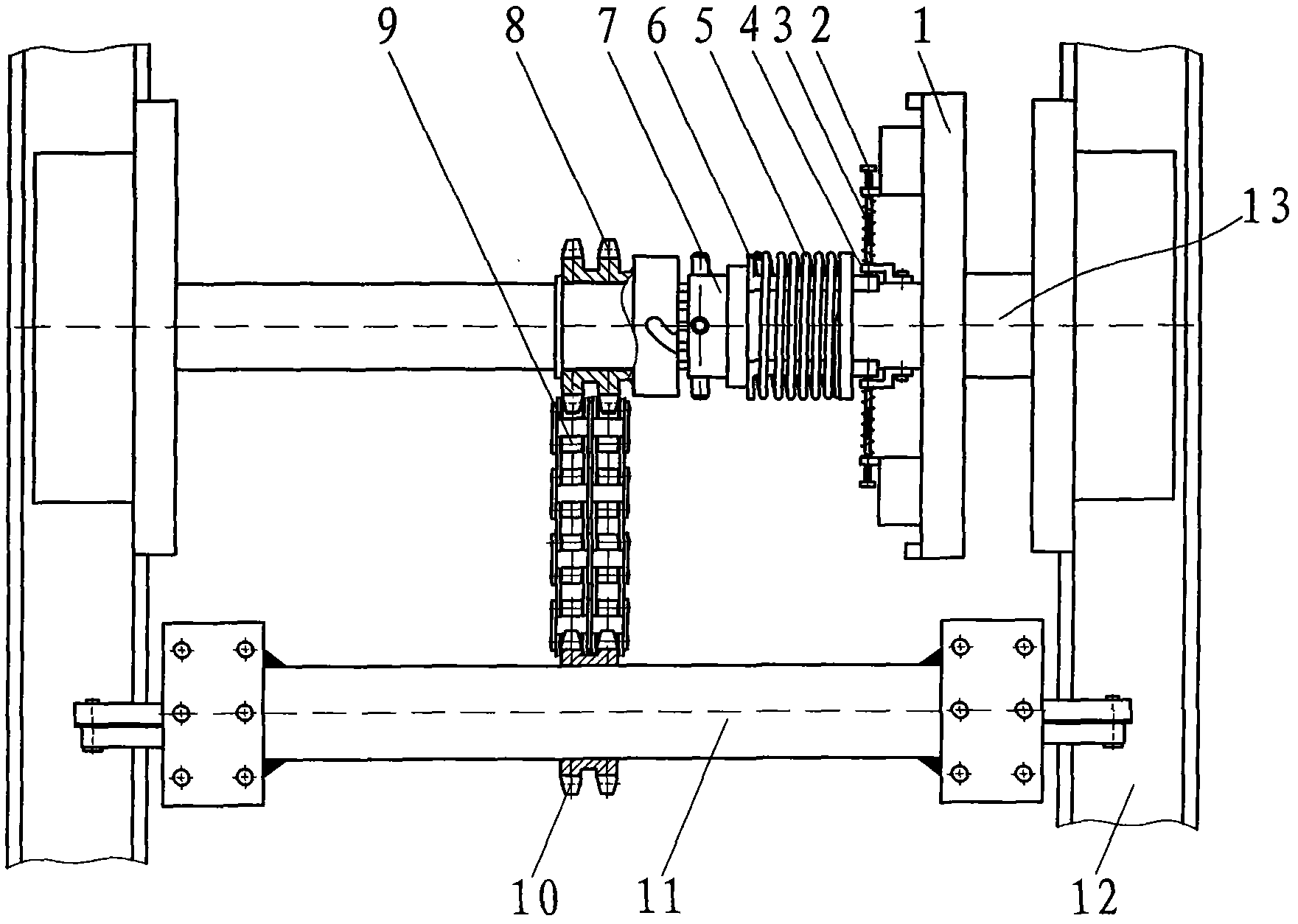

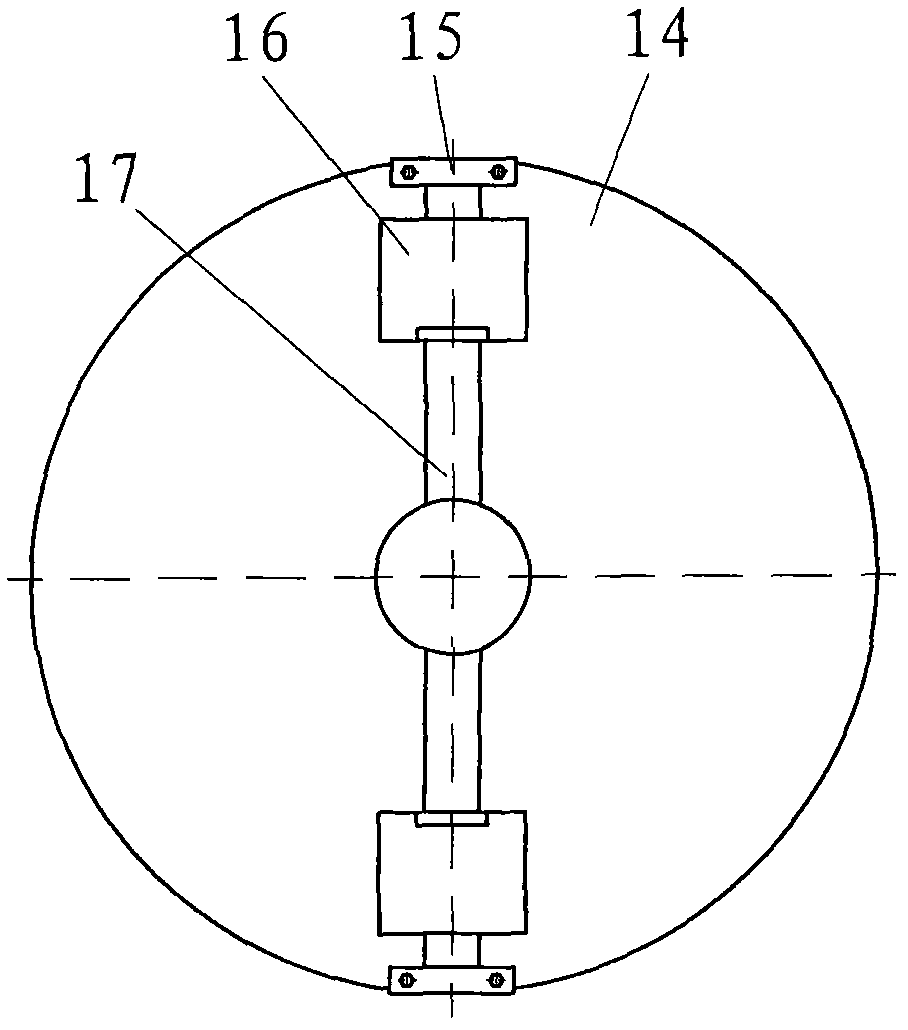

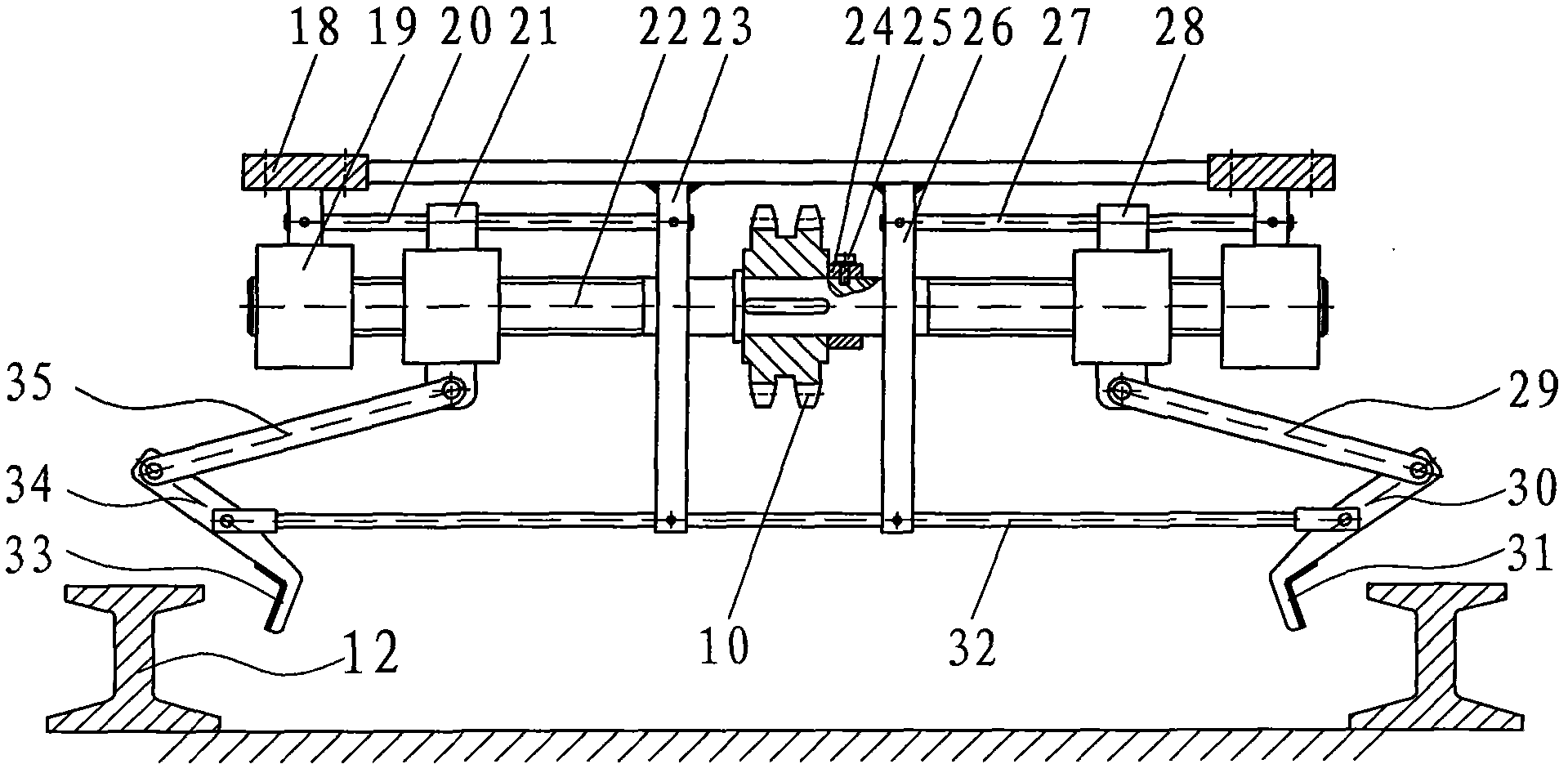

[0013] Such as figure 1 As shown, an active mine car safety braking device is composed of an overspeed sensor 1, a latch 2, a tension spring 3, a positioning block 4, a compression spring 5, an L-shaped arc hook 6, a cross shaft driver 7, and a driving sprocket 8. Chain 9, driven sprocket 10 and brake 11 form. Wherein, the overspeed sensor 1 is fixed on the mine car rear axle 13 by bolts, the positioning block 4 is fixed on the mine car rear axle 13 by screws, one end of the tension spring 3 is fixed on the overspeed sensor 1, and the other end is fixed on the mine car rear axle 13. On the positioning block 4, the overspeed sensor 1, the positioning block 4 and the L-shaped arc hook 6 are connected by the latch 2, the compressi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap