Special measurer for distance between arc and end face of crankshaft

A detector and arc technology, applied in the field of special detectors for the distance between crankshaft arc and end face, can solve the problems of poor measurement effect, time-consuming and laborious, low precision, etc., and achieve the effect of reasonable structure, ensuring accuracy and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

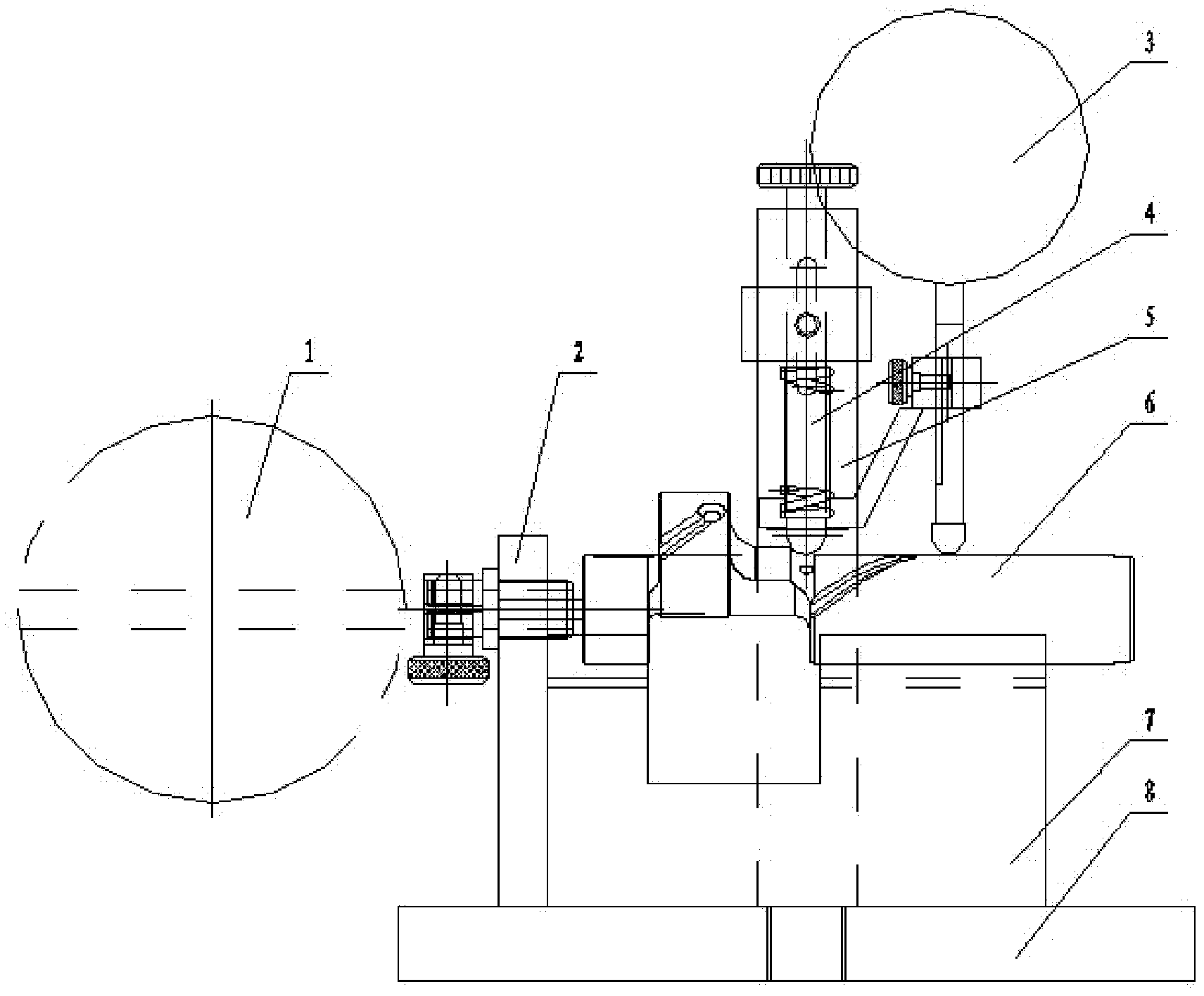

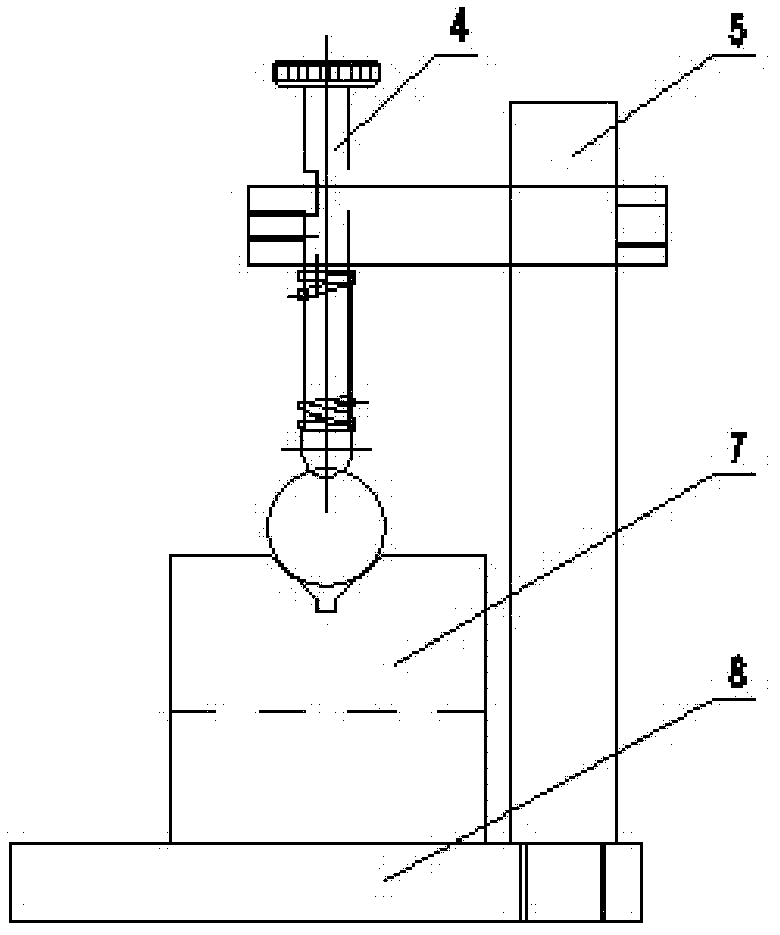

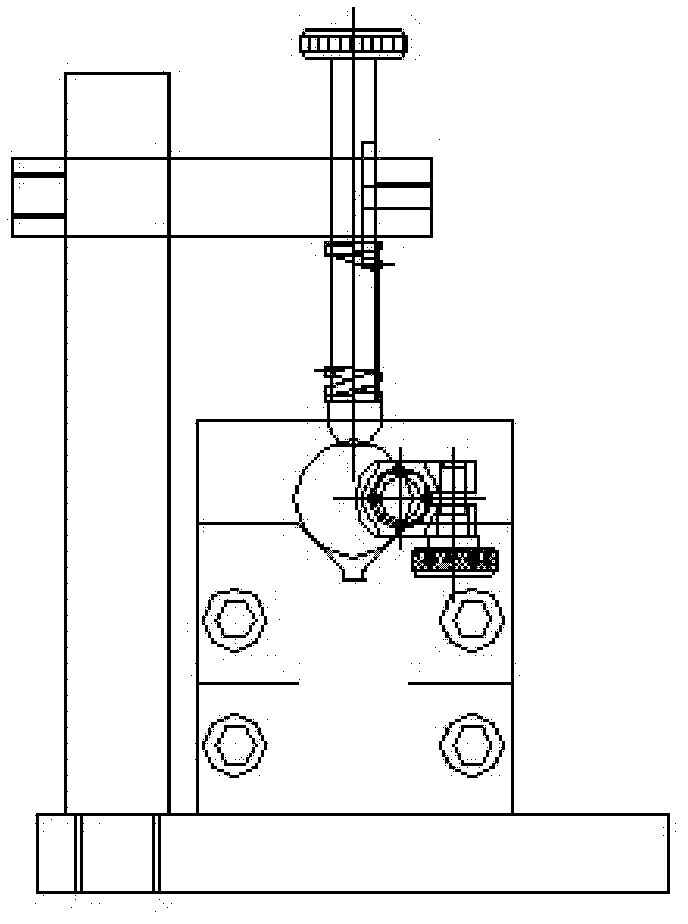

[0015] A special detector for the distance between the arc of the crankshaft and the end face. Its innovative point is that it includes a worktable 8, a workpiece positioning platform 7, a positioning rod 4 and a dial indicator. The workpiece positioning platform is installed on the workbench, and the workpiece positioning platform is made A positioning groove for placing the workpiece 6, the positioning groove is a V-shaped positioning groove.

[0016] A positioning frame 5 is installed on the workbench, and a positioning rod is installed vertically on the horizontal plate of the positioning frame. Springs are sleeved on the positioning rods between them.

[0017] Rotate and install a vertical dial indicator 3 positioned at the workpiece t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com