Bounce measurement tool of inner hole and external diameter of deep-hole part

A technology of parts and inner holes, applied in the field of inner hole and outer diameter runout measuring tools, can solve problems such as difficult to improve measurement speed accuracy, engine vibration, inconvenient operation, etc., and achieve the effect of improving measurement speed and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

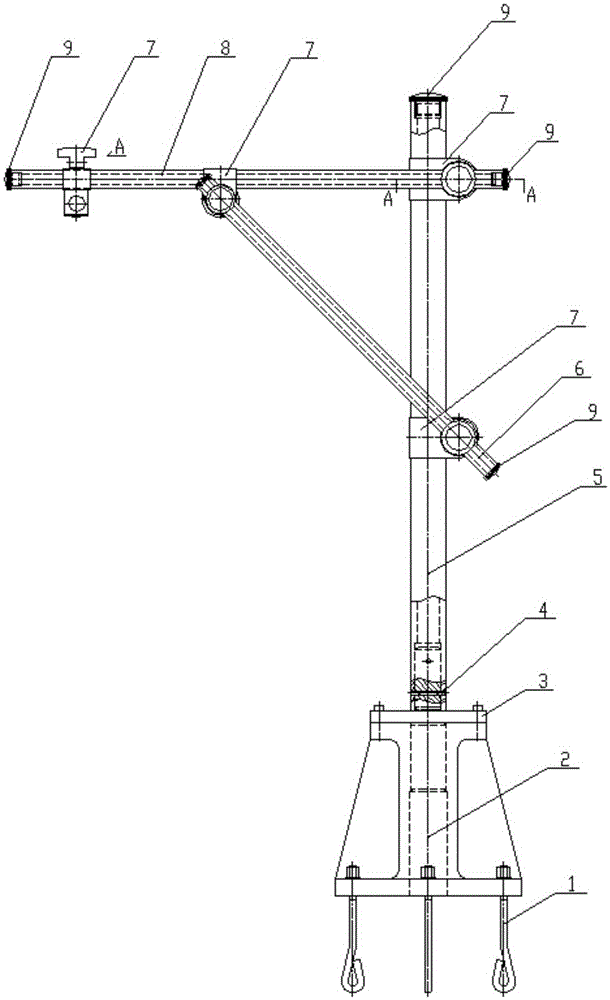

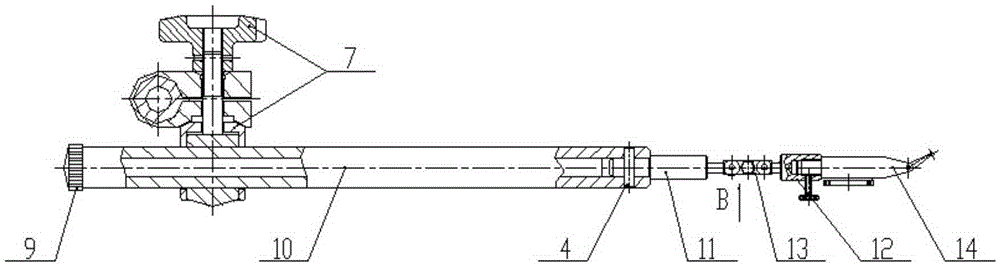

[0031]In this embodiment, the inner hole and the outer diameter runout measuring tool of the deep hole parts are as follows figure 1 , figure 2 As shown, it includes a base 2, a connecting body 3, a pillar 5, a support rod 6, a beam 8, an adapter rod 10, a connecting assembly 7, a movable rod 11, a table holder 12, a splint 13 and a dial indicator 14.

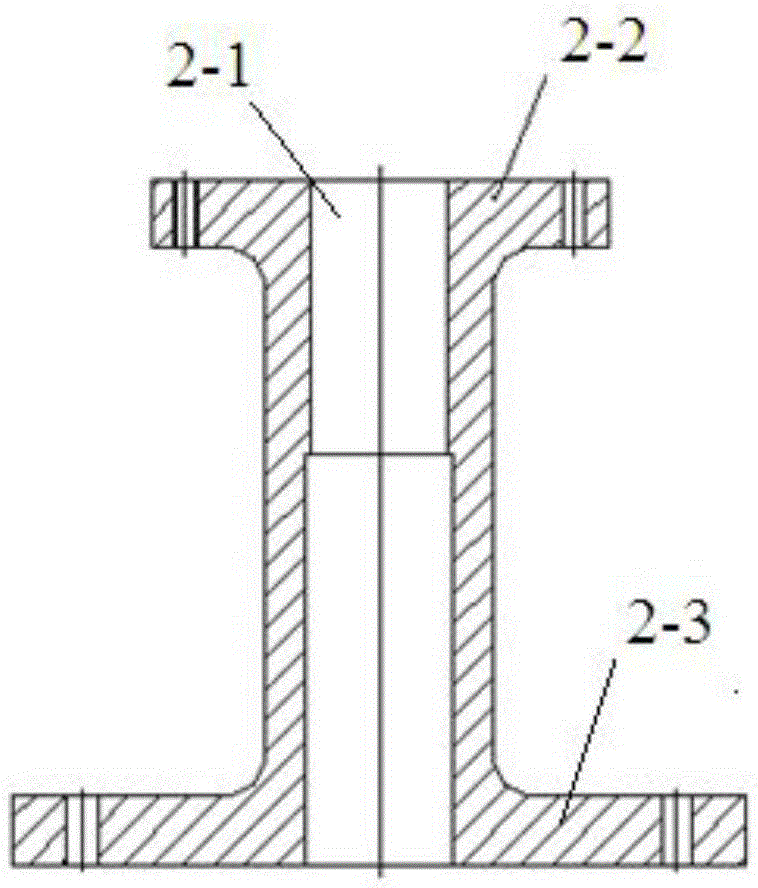

[0032] The base 2 is as image 3 , Figure 4 As shown, the cylinder with the socket 2-1 in the center, the upper flange 2-2, the lower flange 2-3 located at both ends of the cylinder, and the reinforcement connecting the upper flange and the lower flange Rib 2-4 constitutes; Described pillar 5 is the bar with central hole (see figure 1 ), the linker 3 such as Figure 5 As shown, it is composed of a flange 3-1 and a first connecting rod 3-2 and a second connecting rod 3-3 located on both sides of the flange. The nominal size of the aperture is the same, and it is a dynamic fit. The outer diameter of the second connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com