Process for manufacturing tyres for vehicle wheels

A wheel and tire technology, applied in vehicle parts, tire parts, tires, etc., to achieve the effect of increasing production output and low initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

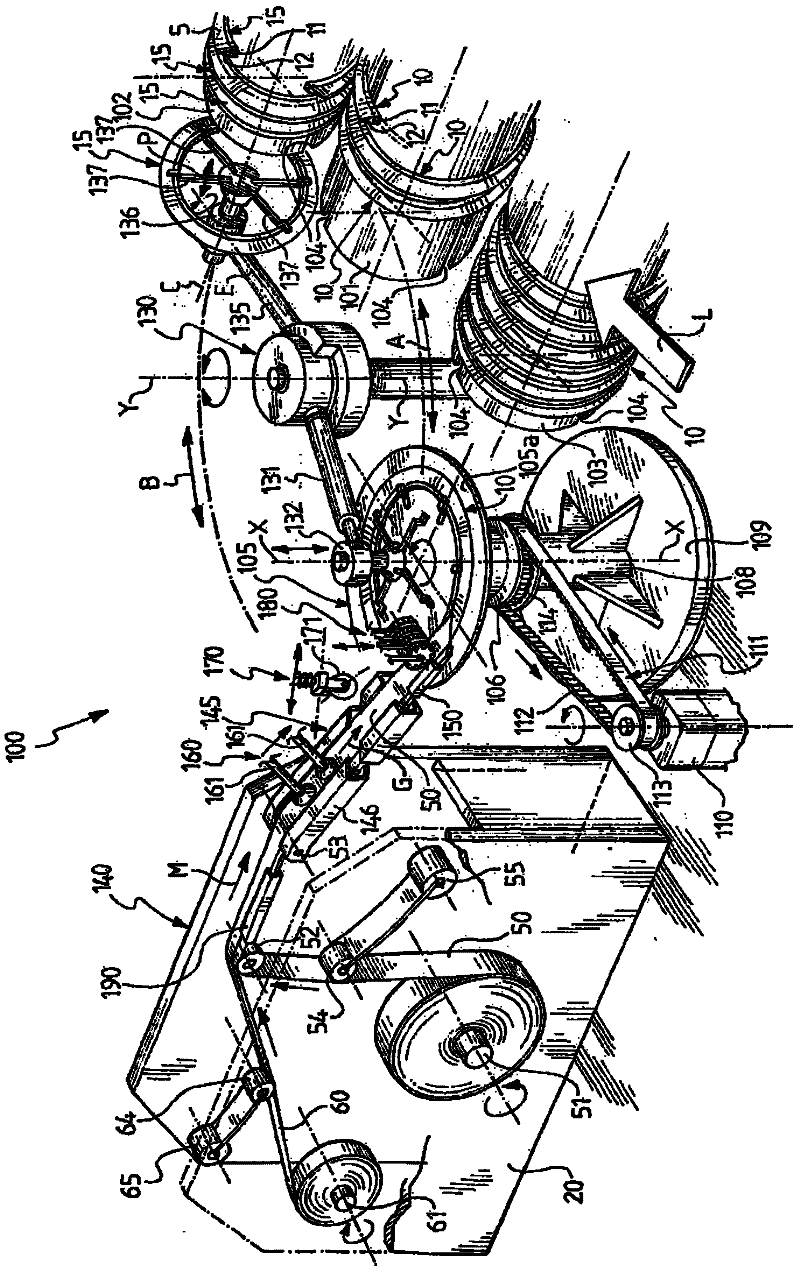

[0140] exist figure 1 In , reference number 100 generally indicates an exemplary embodiment of a device for inserting a ring-shaped reinforcing element 5 ( Figure 9 ) is placed on the annular anchoring structure 10 of a tire for a vehicle wheel in order to make a reinforced annular anchoring structure 15. The device 100 allows performing a placement process according to the invention.

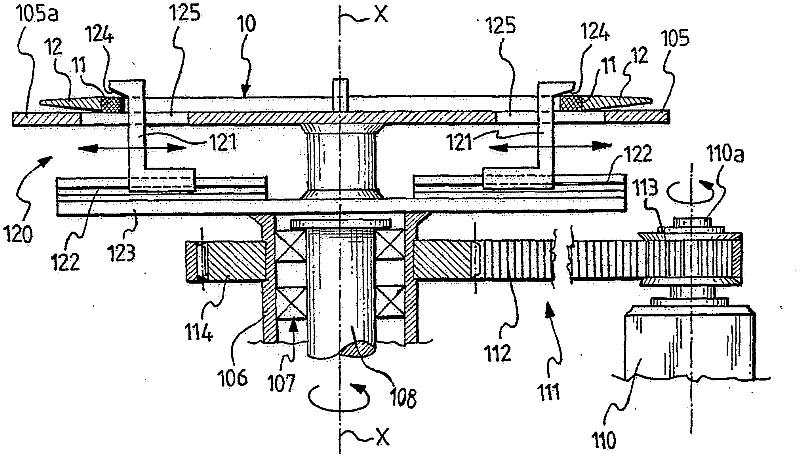

[0141] like figure 1 , 2 and 9, the annular anchoring structure 10 comprises: a substantially circumferential annular insert 11, also referred to as a bead core; The radially outer position of is connected to said substantially circumferential annular insert 11 .

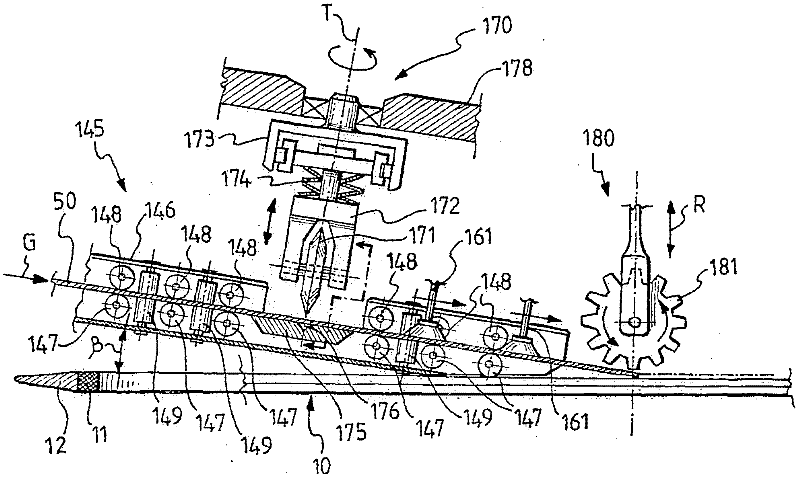

[0142] Through the device 100 and placement process of the present invention, the annular reinforcing element 5 is attached to the side surface 12a of the filling element 12 of the annular anchoring structure 10 ( Figure 9 ).

[0143] Figure 9 An annular reinforcing element 5 placed at the full radial extension of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com