Fully automatic coffee machine with a position detection device and/or adjustment speed detection device

A detection device, coffee machine technology, applied in the direction of linear/angular velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., can solve the problems of inaccuracy and reciprocity of filling height determination, and achieve compact and easy-to-implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

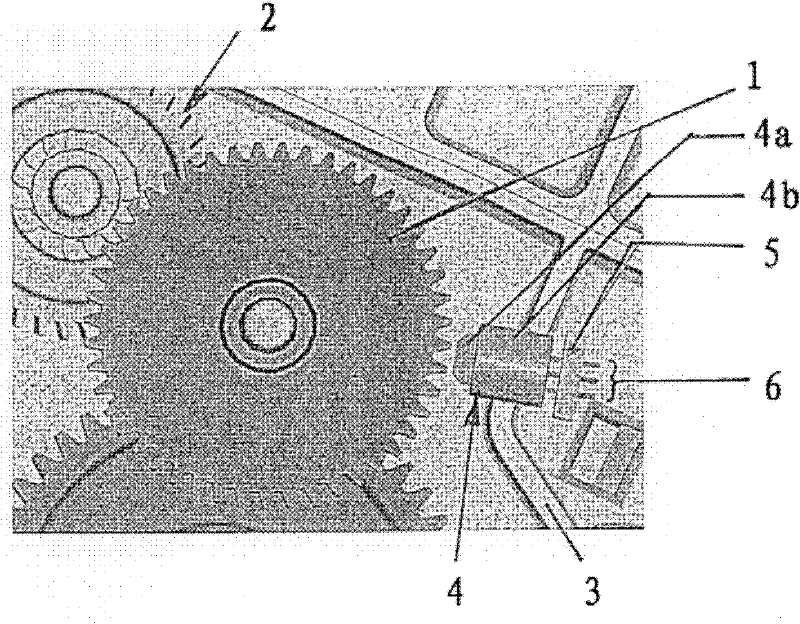

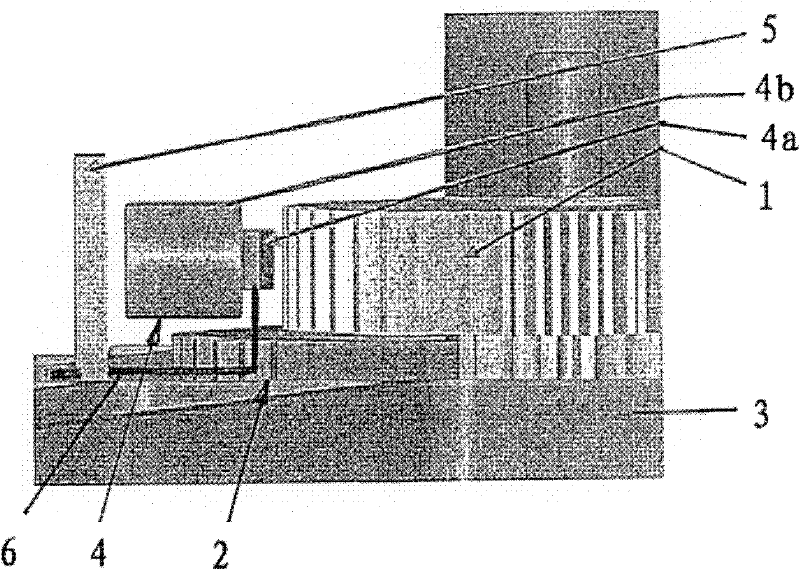

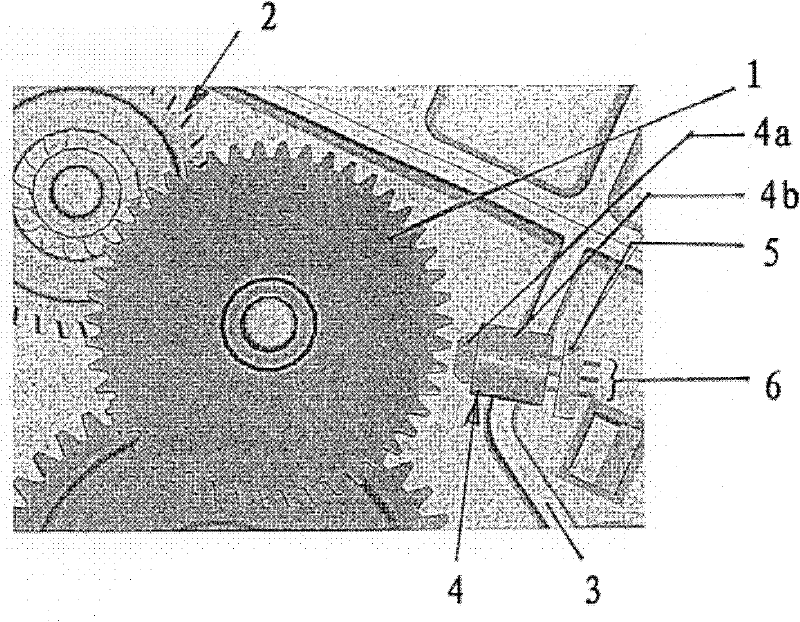

[0020] exist figure 1 and 2 shows a ferromagnetic gear 1 with straight toothing, which is made of a ferrous alloy and is part of a transmission denoted overall by 2 . The transmission 2 is driven by an unshown DC motor.

[0021] The components of the transmission 2 including the ferromagnetic gear 1 are mounted rotatably on a mounting plate 3 of the fully automatic coffee machine. A DC motor driving the transmission 2 is not visible.

[0022] Radially facing the teeth of the ferromagnetic gear 1 and at the same height as the teeth, a Hall sensor / magnet unit 4 is mounted on the mounting plate, precisely by means of a mounting plate 3 and connected to the interface 6 The printed circuit board 5 is contacted. These interfaces 6 lead to an electronic control unit (not shown), a counter or an analog-to-digital converter.

[0023] as by figure 1 and 2 As can be seen in detail, the Hall sensor 4a of the Hall sensor / magnet unit 4 is arranged between a permanent magnet 4b and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com