Fixture used for testing thickness and deflection of battery and test method by using same

A technology for detection fixtures and detection methods, which is applied in the direction of mechanical thickness measurement, mechanical counter/curvature measurement, etc., can solve the problems of uneven battery thickness, unusable, and excessively large warped parts of the battery, and achieve multi-point detection , Realize simultaneous management and strengthen the effect of overall management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, the thickness and deflection detection jig of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the specific aspects described below.

[0048]

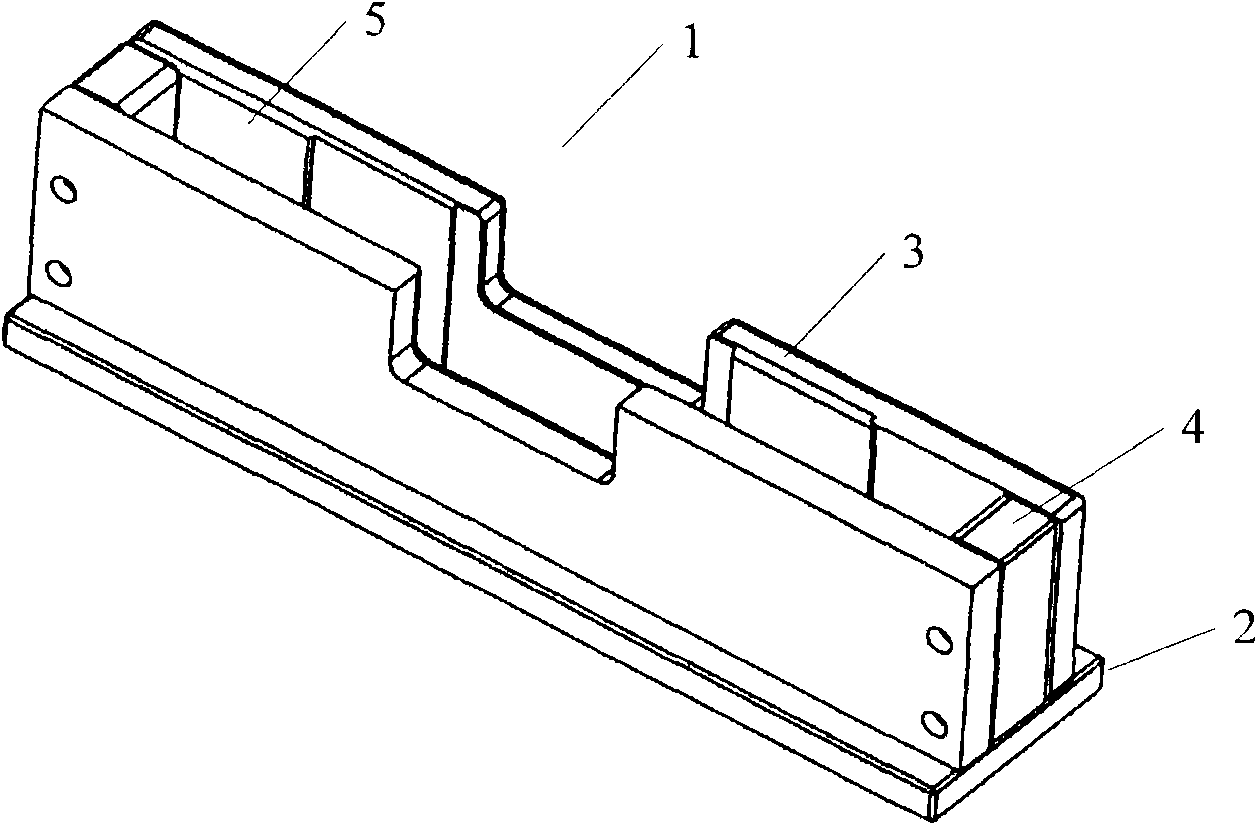

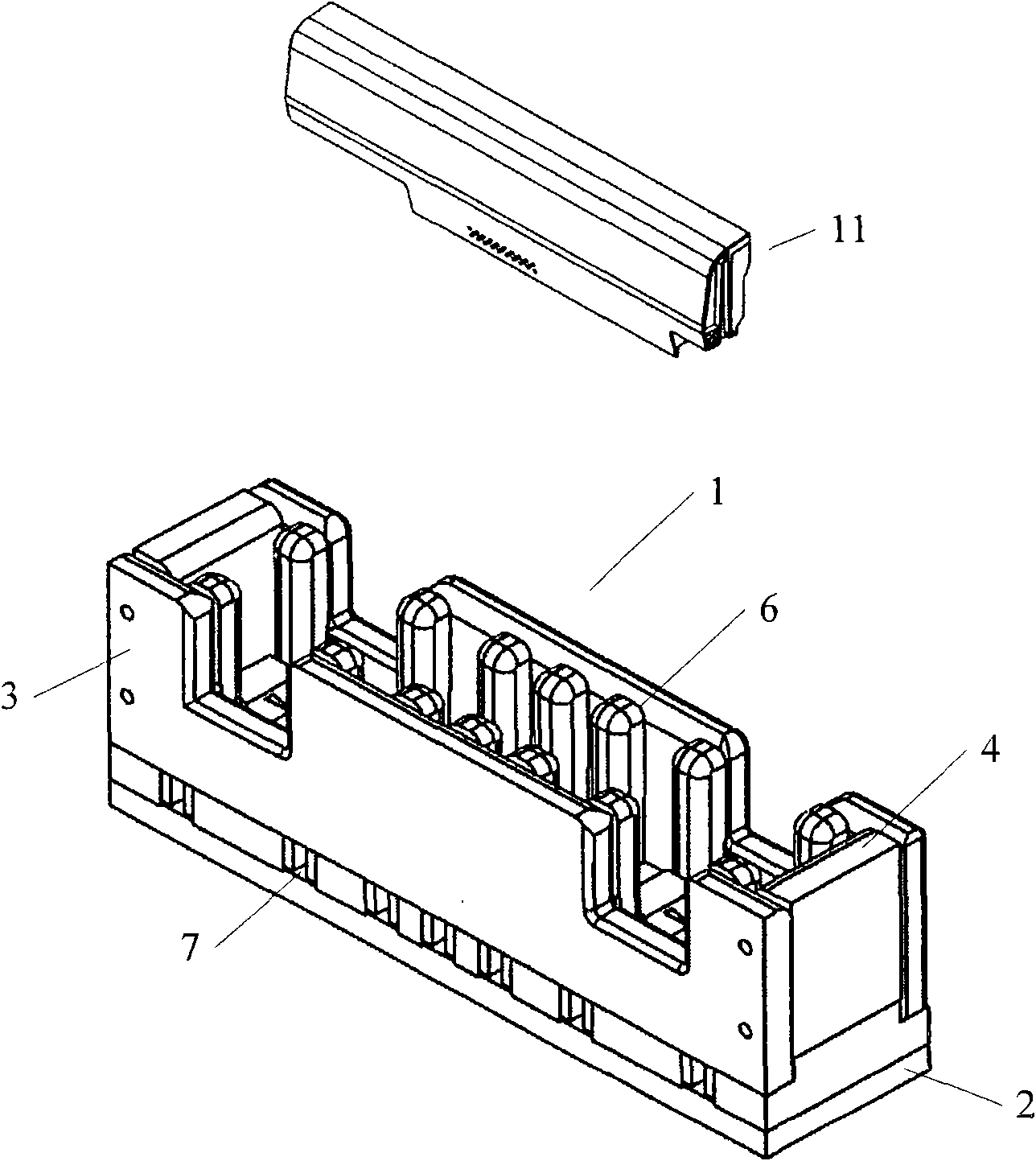

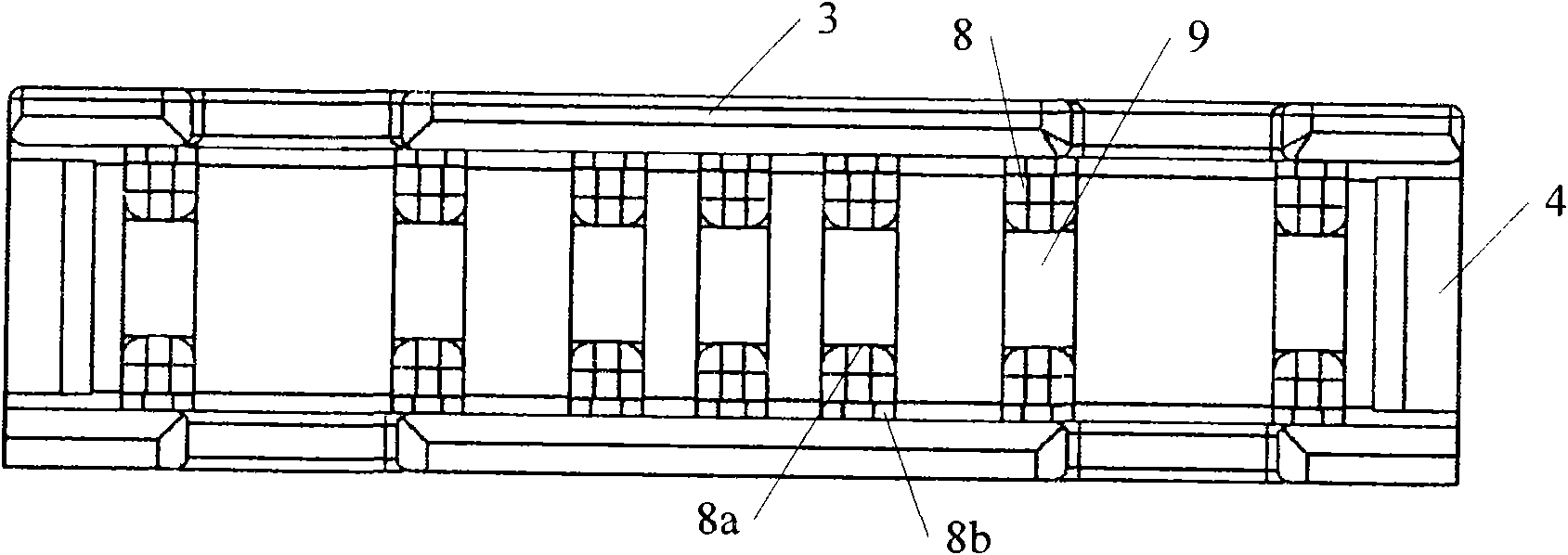

[0049] First, refer to figure 2 The detection jig of the present invention will be described.

[0050] Such as figure 2As shown, the detection fixture 1 of the present invention comprises a base plate 2, a pair of parallel side plates 3 perpendicular to the base plate 2, a pair of end plates 4 connecting the pair of side plates at the ends of the two side plates, and a A plurality of detection parts 6 between the pair of side plates 3 . The detection unit 6 is accommodated in a measurement tank surrounded by the side plate 3 , end plate 4 and bottom plate 2 . The detection part 6 is opened at the top, and the inner wall is formed as an insertion groove for inserting the battery to be tested. There is a gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com