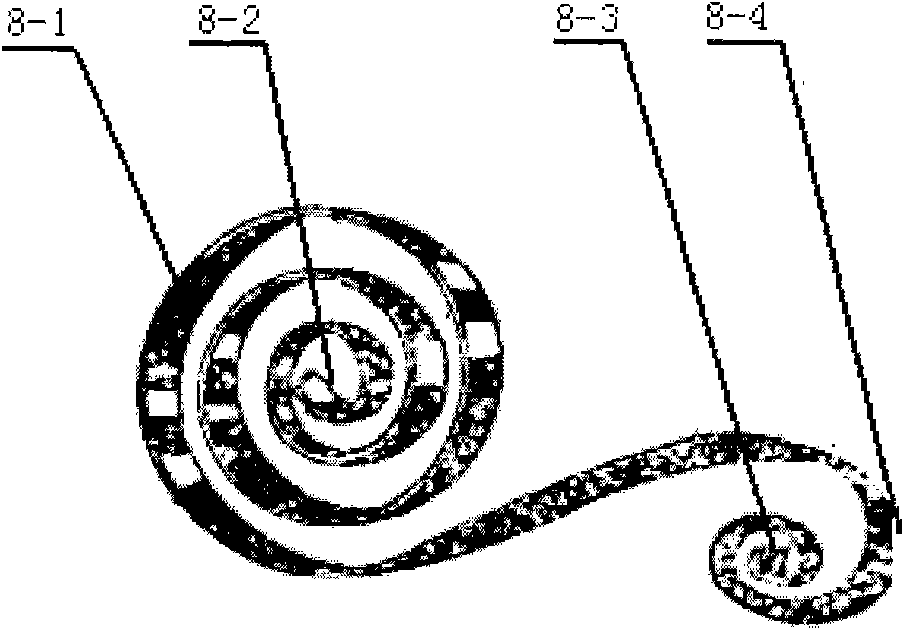

S-shaped spring of timer

A timer and clockwork technology, which is applied to the ratchet mechanism of the clockwork, winding the clockwork in a conventional way, instruments, etc., can solve the problems of affecting the speed of the gear rotation and reducing the accuracy of the timer travel time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the invention will be further described:

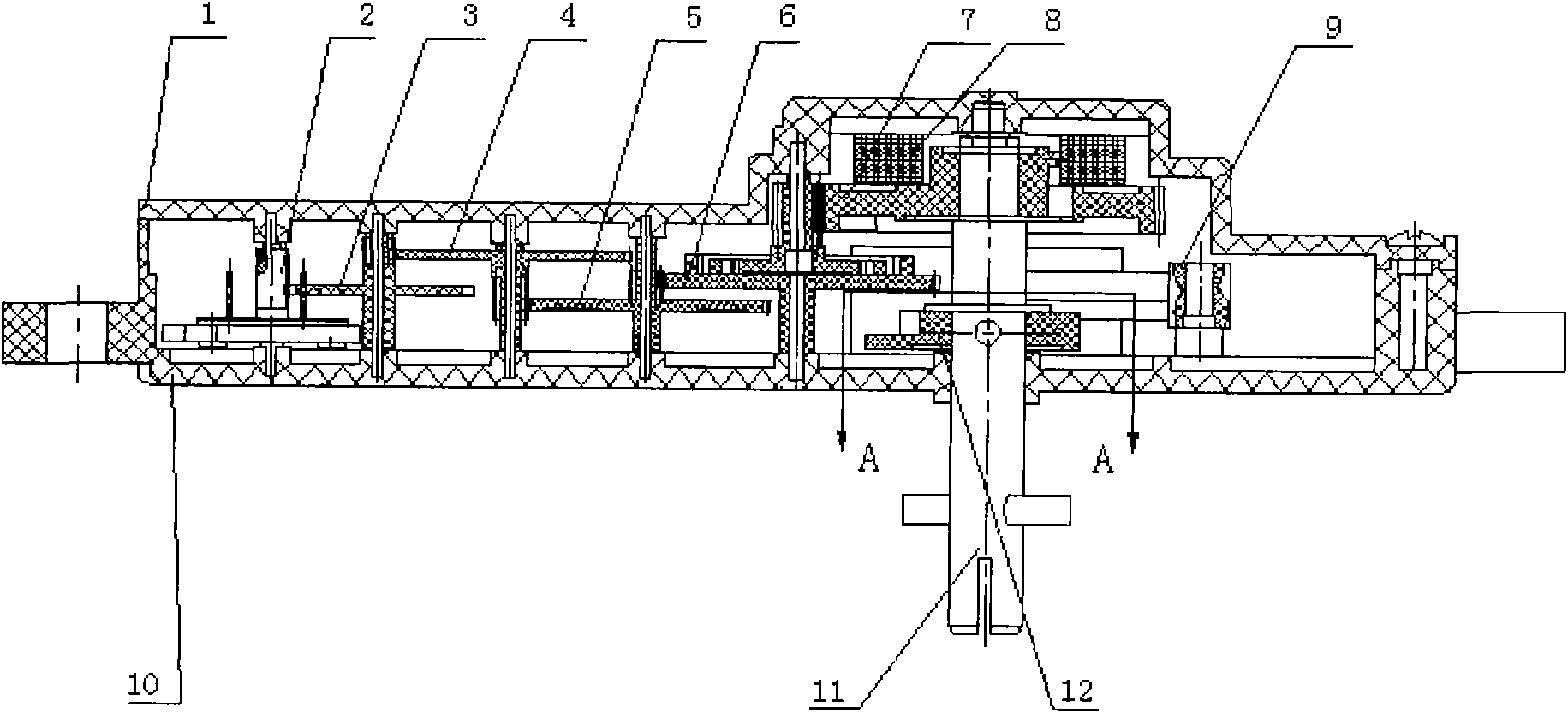

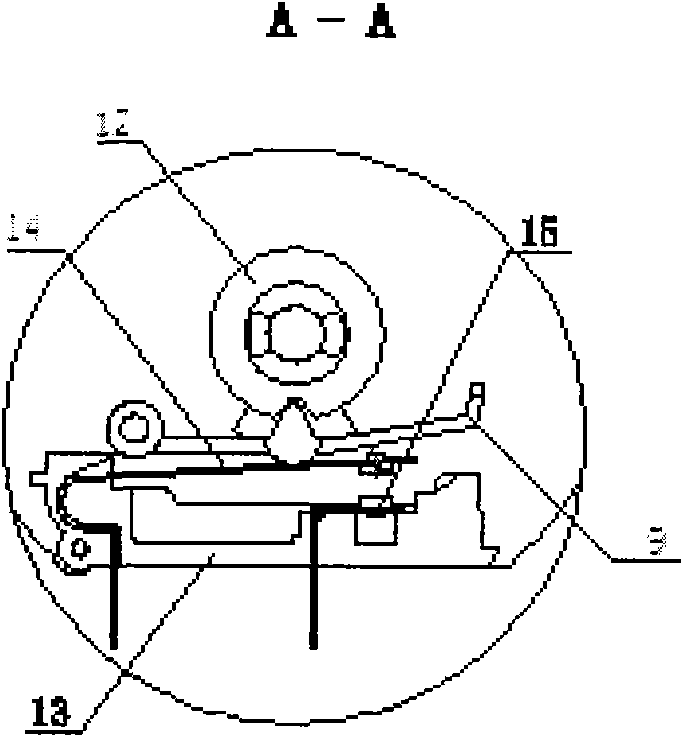

[0011] As shown in the figure, the housing of the timer is composed of the casing 1 and the base 10, and an S-shaped mainspring 8 is installed in the housing to connect the head wheel 7, the second wheel 6, the third wheel 5, and the fourth wheel 4 to realize speed-up. The longitudinal wheel 3 and the balance wheel 2 are released to control the time, and the timing is triggered by the lever 9, the cam 12, the breaking seat 13, the moving reed 14 and the static reed 15 breaking and closing. The S-shaped mainspring 8 is "S"-shaped no matter when it is loose or tight, and the moments of the inner and outer rings are mutually restrained, so that the output moments are always relatively balanced, so the escapement on the gear set The active force of the wheel is also relatively constant, which achieves the purpose of improving the accuracy of the timer travel time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com