Movement with pure-tungsten metal clamp plates

A metal splint and movement technology, applied to mechanically driven clocks, instruments, structures, etc., can solve the problems of unfavorable watch travel time accuracy, large temperature coefficient, deformation, etc., achieve low expansion coefficient, small temperature coefficient, and simplify the movement structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

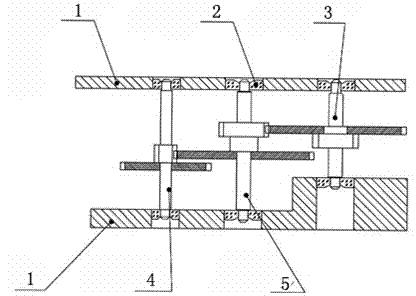

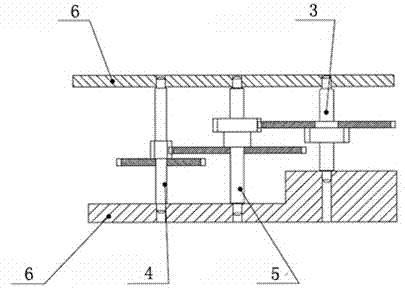

[0032] Such as figure 2 As shown, a movement using a pure tungsten metal splint includes a movement and a splint supporting the movement. In the present invention, the splint is made of pure tungsten metal material, and its density is 19.35 g / cm 3 In this embodiment, the movement is a quartz movement, so the movement only includes a transmission mechanism, which includes a first transmission wheel group, a second transmission wheel group, and a third transmission wheel group vertically arranged between the splints. , The first transmission wheel group meshes with the third transmission wheel group, the third transmission wheel group meshes with the second transmission wheel group, the first transmission wheel group, the second transmission wheel group and the third transmission wheel group all include horizontally arranged on the splint Since the transmission mechanism between the gears and the respective gear shafts is an existing part of the watch movement, the specific struc...

Embodiment 2

[0040] A movement that uses a pure tungsten metal splint. The difference from Embodiment 1 is that the movement used in this embodiment is a mechanical movement, and the splint is made of pure tungsten metal material with a density of 19.35 g / cm 3 Therefore, the movement of this embodiment includes a transmission mechanism, an escapement speed regulation mechanism and other auxiliary mechanisms. Among them, the structure of the transmission mechanism, escapement speed regulation mechanism and other auxiliary mechanisms belongs to the prior art and will not be repeated here. . The structure of the transmission mechanism of the mechanical movement and the quartz movement is the same. The transmission mechanism includes a first transmission wheel group, a second transmission wheel group and a third transmission wheel group which are vertically arranged between the clamping plates. The third transmission wheel group meshes, the third transmission wheel group meshes with the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com