Capacitive touch board for improving linear response

A capacitive touch, linear response technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve the problem of low object positioning recognition rate, insignificant capacitance change, large Y coordinate nonlinearity response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

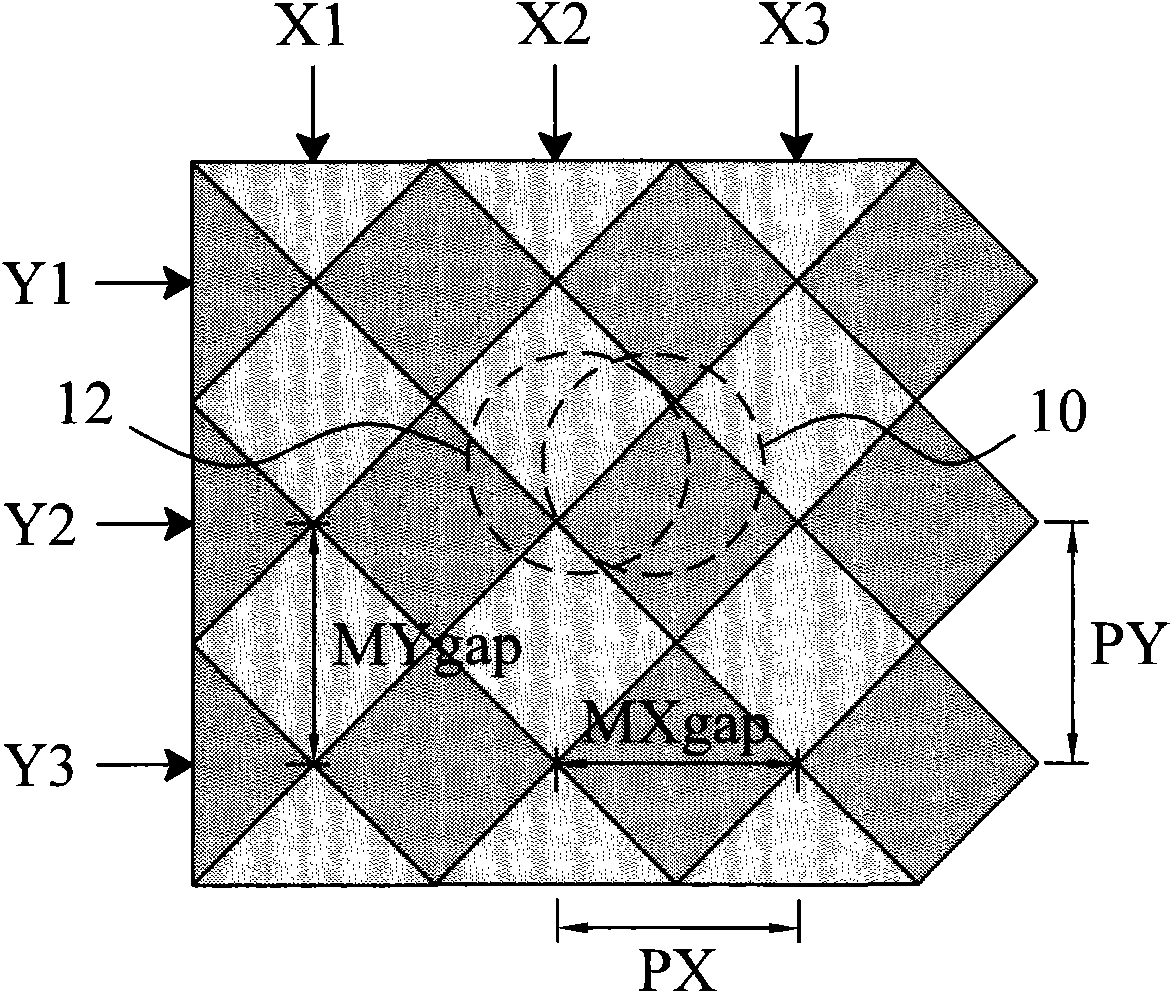

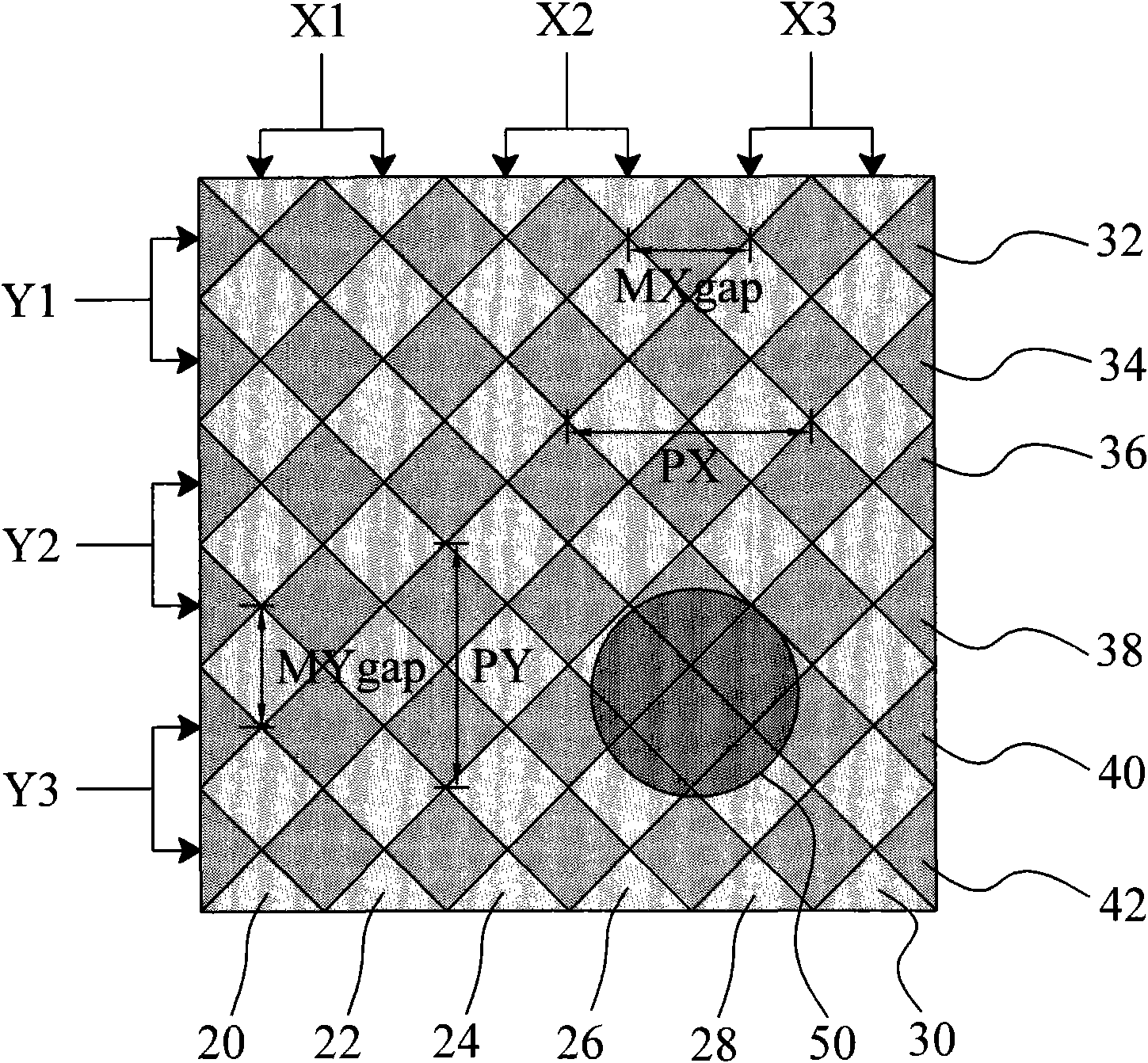

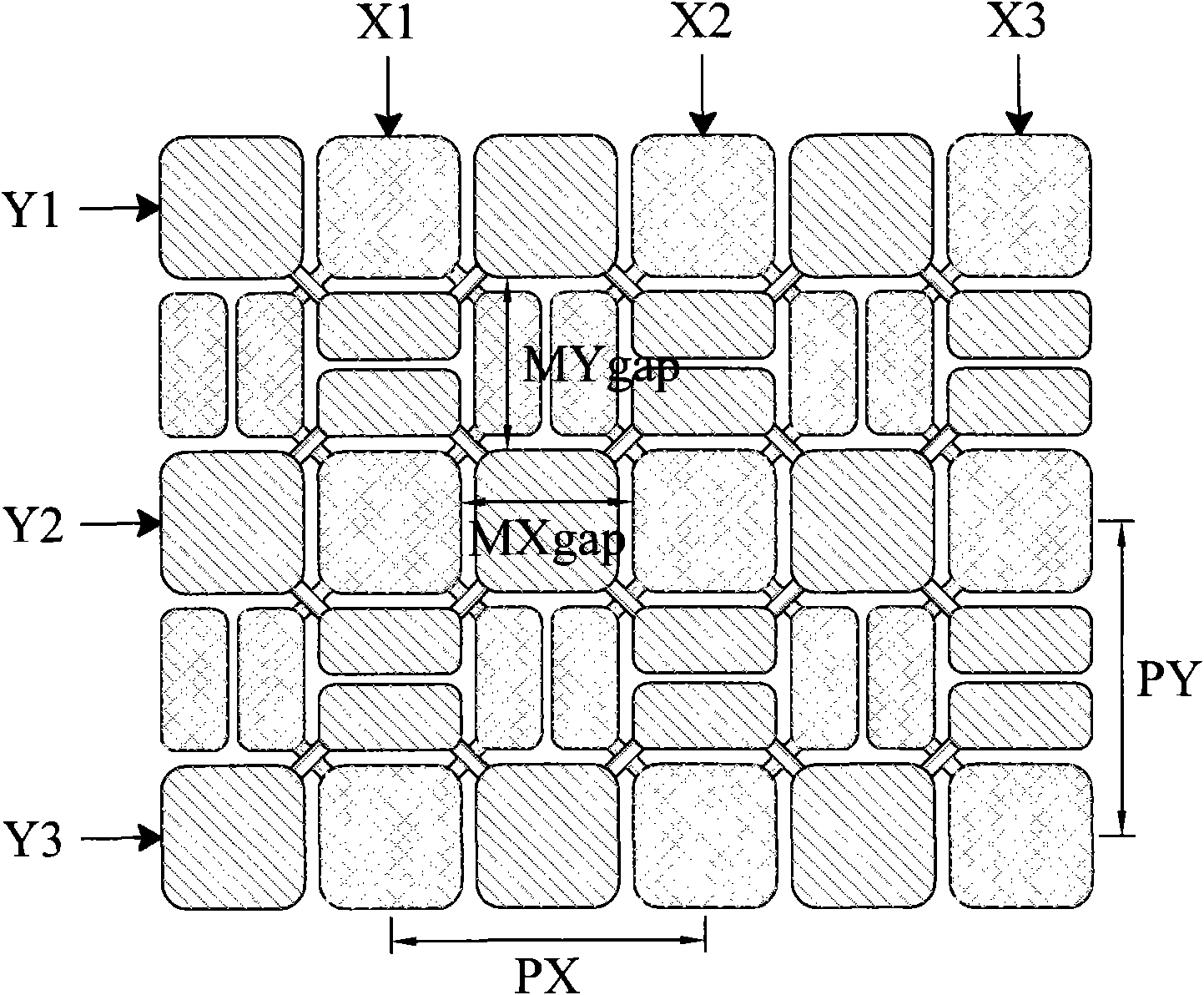

[0014] figure 2 According to the first embodiment of the present invention, the capacitive touch panel has a plurality of parallel traces 20, 22, 24, 26, 28 and 30 in the X direction and a plurality of parallel traces 32, 34, 36, 36 in the Y direction. 38, 40 and 42, wherein the traces 20 and 22 are electrically connected to form the sensor X1 in the X direction, the traces 24 and 26 are electrically connected to form the sensor X2 in the X direction, and the traces 28 and 30 are electrically connected to form the X direction Traces 32 and 34 are electrically connected to form an inductor Y1 in the Y direction, traces 36 and 38 are electrically connected to form an inductor Y2 in the Y direction, traces 40 and 42 are electrically connected to form a sensor in the Y direction Device Y3. The traces in the X direction and the Y direction can be electrically connected inside or outside the touch panel to form a sensor. The distance between the centers of adjacent inductors in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com