Soft packaging optical fiber grating sensor with vernier wavelength

A fiber grating and sensor technology, applied in the field of sensors, can solve problems such as unfavorable application of wavelength division multiplexing technology, reduction of sensing measurement range, unfavorable multi-point measurement, etc., and achieve favorable multiplexing, good cost performance, and linearity Good response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

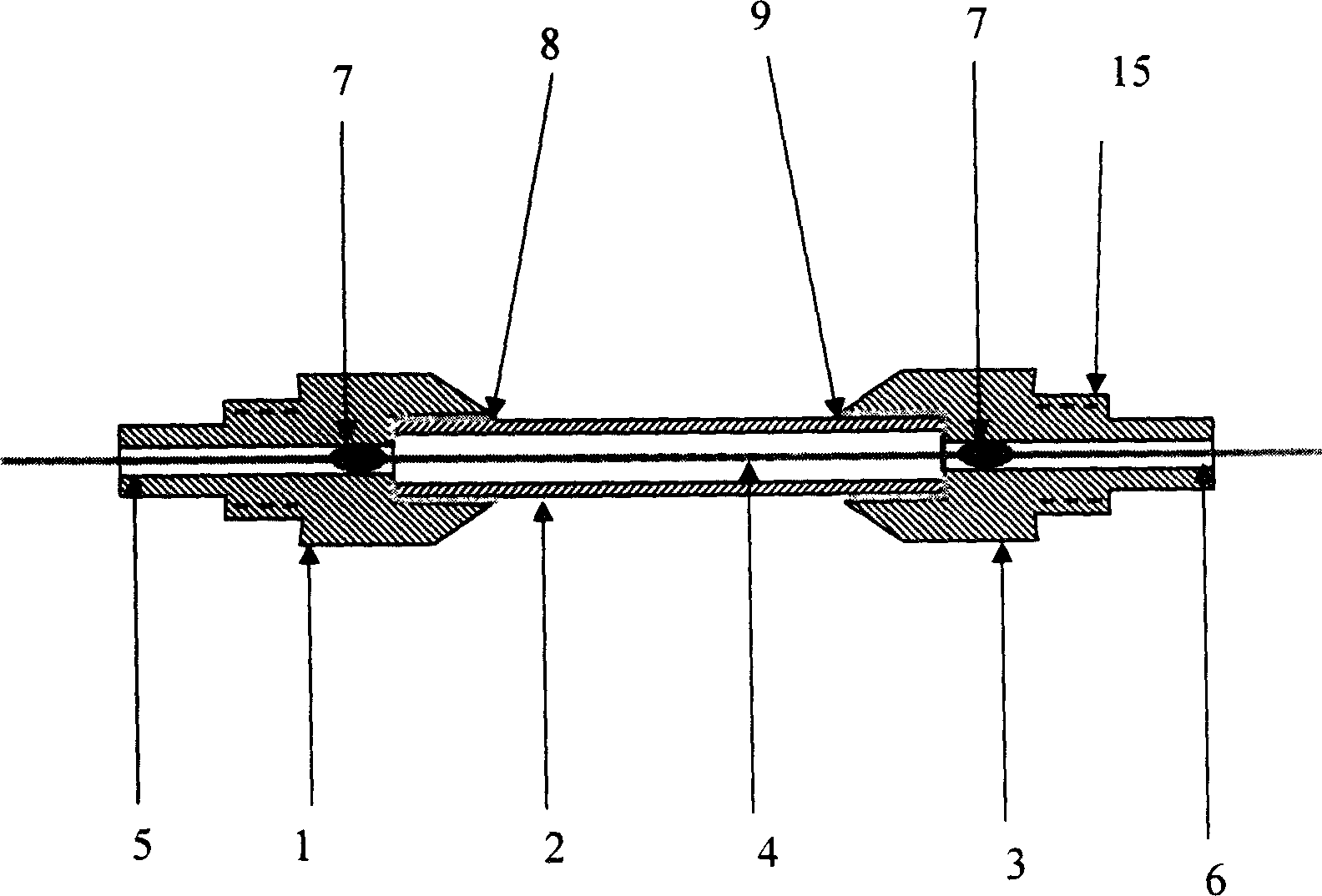

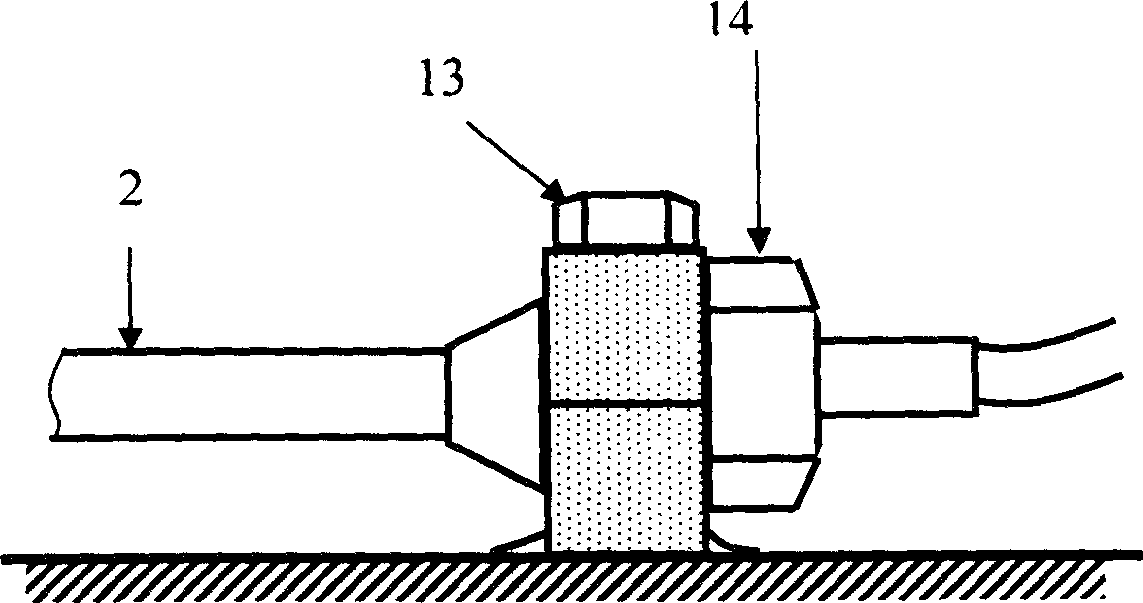

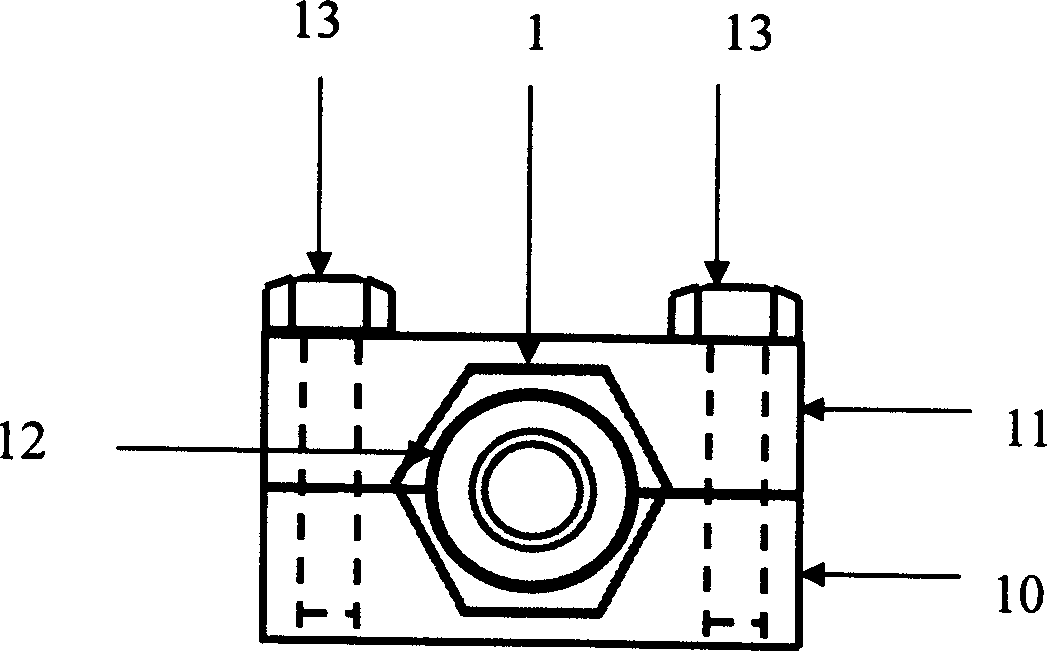

[0024] see first figure 1 , figure 2 and Figure 3 Show, figure 1 , figure 2 and Figure 3 is The embodiment of the soft-packaged fiber grating sensor with fine-tunable wavelength of the present invention can be seen from the figure, the fiber Bragg grating sensor with fine-tunable wavelength of the present invention includes an optical fiber section of fiber grating 4, and the optical fiber section passes through the protective sleeve 2, the first The first small hole 5 in the middle of the clamp 1 and the second small hole 6 in the middle of the second clamp 3, the two ends of the protective sleeve 2 are respectively connected with the first clamp 1 and the second clamp 3 with soft glue 8 and adhesive 9 For bonding, straighten the fiber section containing the fiber grating 4 and ensure that the fiber grating 4 is in the middle of the protective sleeve 2, fill the first small hole 5 and the second small hole 6 with fixing glue 7 and the second small hole respectively A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com