Equipment for complex production of special concrete additive

A production equipment and admixture technology, applied in the field of concrete admixture production equipment, can solve the problems of single rotation direction, low batching accuracy, high equipment cost, etc., and achieve the effect of saving electric energy, fully mixing, and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

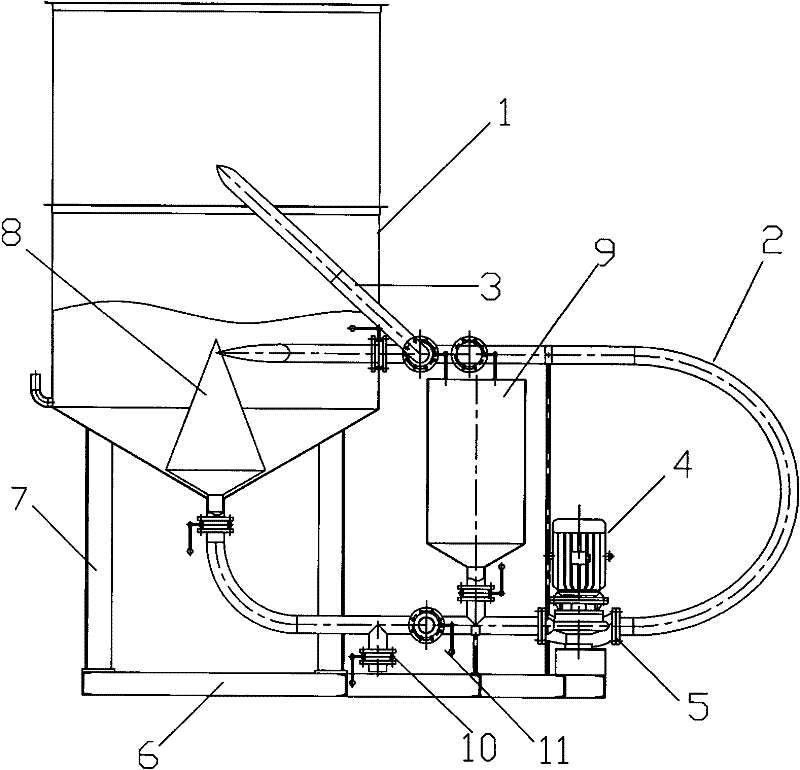

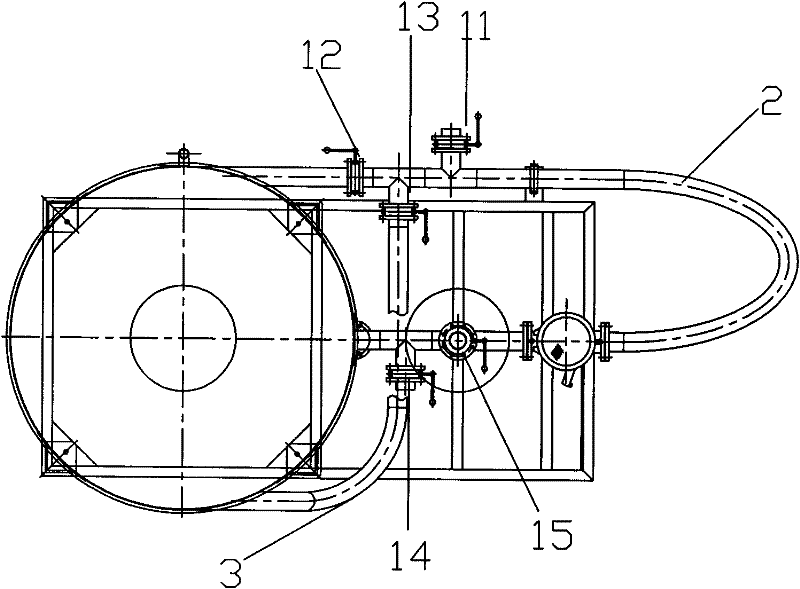

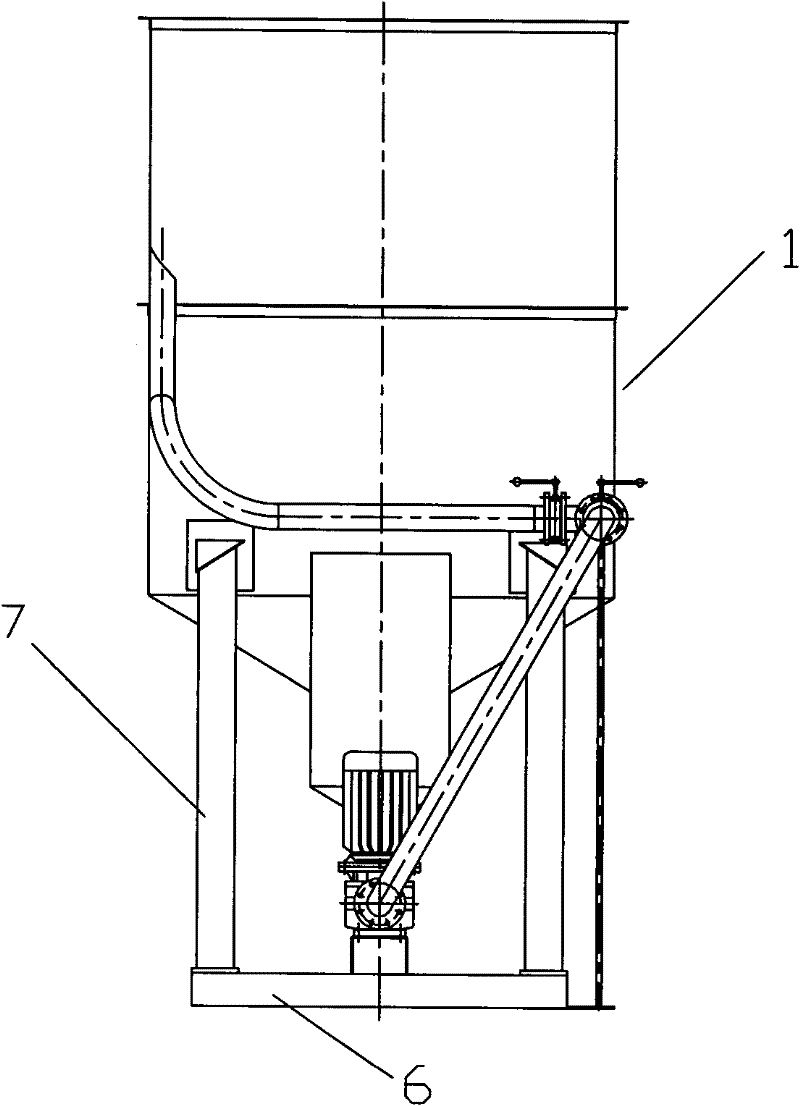

[0021] See attached figure 1 , figure 2 , image 3 , the present invention is a compound production equipment for special concrete admixture, which consists of a mixing tank 1, an arc pipe 2, an auxiliary elbow pipe 3, a motor 4, a liquid special pump 5, a base 6, a bracket 7, a cone 8, and a feeding hopper 9. Cleaning valve 10, feed inlet 11, 12-15, wherein, the arc tube 2 is connected with the mixing tank 1 on the right side of the mixing tank 1, and the auxiliary elbow 3 is connected with the mixing tank 1 on the left side of the mixing tank 1. connected. One end of the arc tube 2 communicates with the upper part of the mixing tank 1 through a valve, the other end of the arc tube 2 communicates with the bottom of the mixing tank 1 through a valve, and the auxiliary elbow 3 is connected to the mixing tank 1 through a valve. Betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com