Chemical reaction kettle capable of efficiently and circularly stirring and use method of chemical reaction kettle

A technology of cyclic stirring and chemical reaction, which is applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical processes, etc., can solve unsatisfactory production effects, long material reaction time, and low production efficiency. Advanced problems, to achieve the effect of good stirring effect, high stirring efficiency and sufficient circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

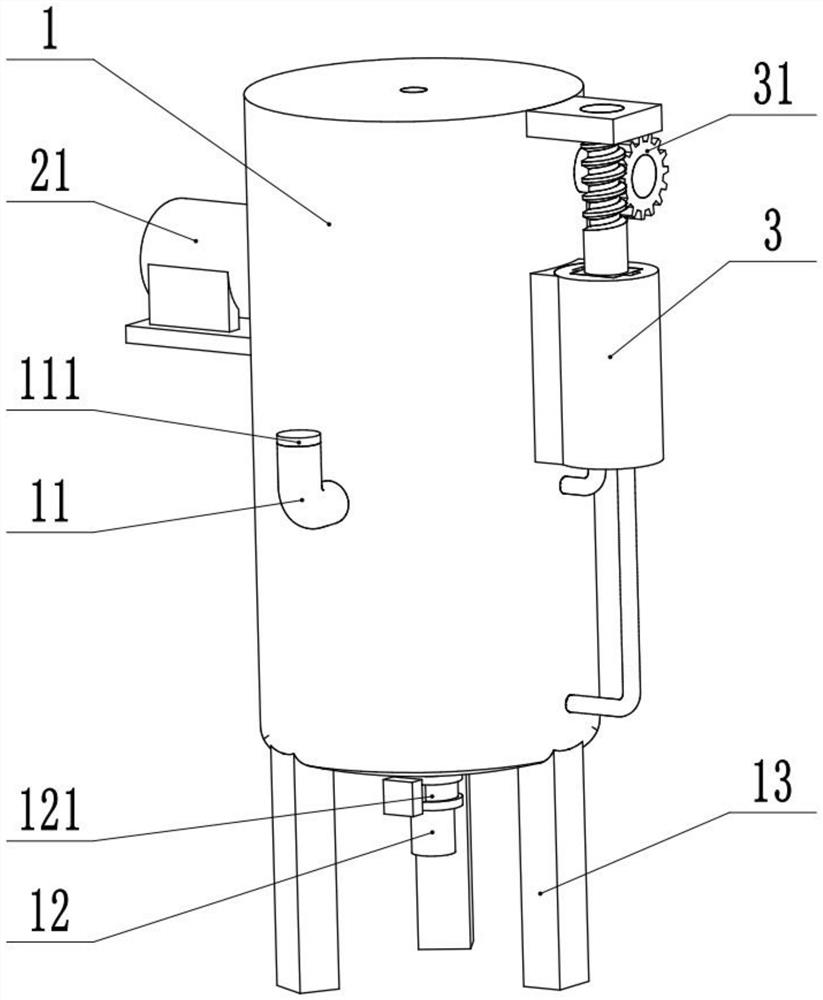

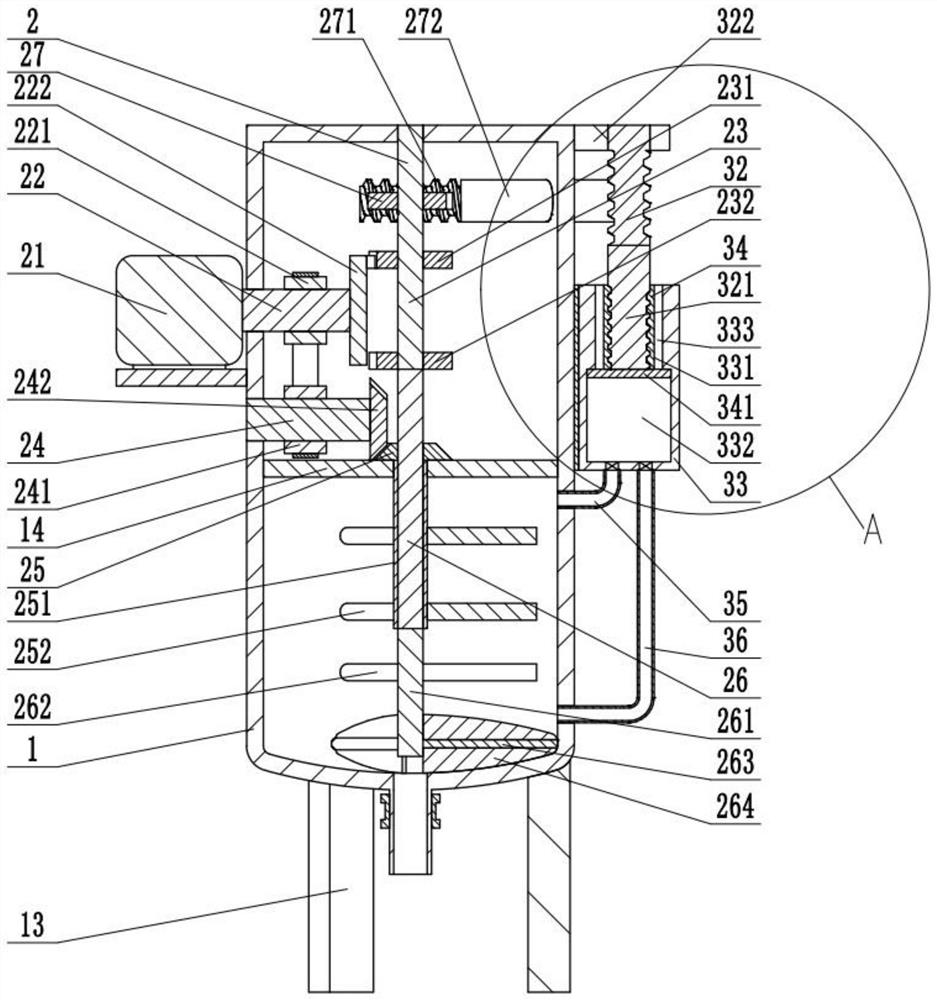

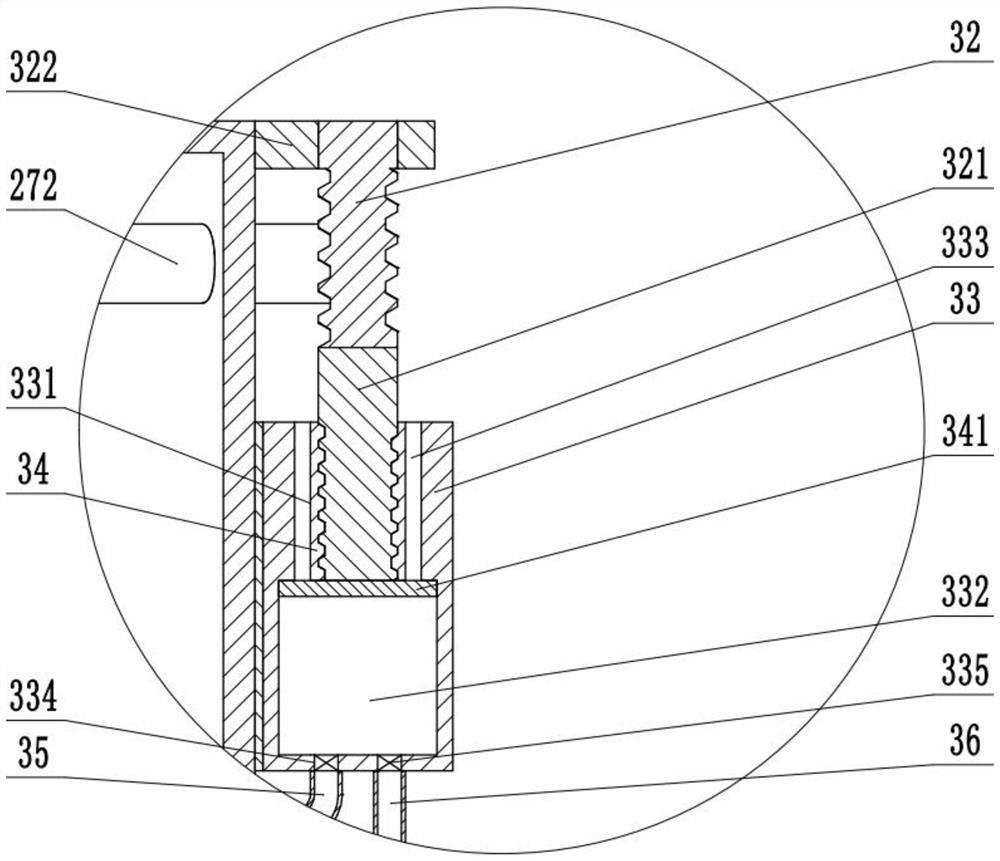

[0024] Such as figure 1 , figure 2 and Figure 5 Shown: in this embodiment, a chemical reaction kettle with high-efficiency circulation stirring includes a support frame 13, a housing 1 fixedly connected to the upper end of the support frame 13, a stirring mechanism 2 installed in the housing 1, and a 1 The circulation mechanism 3 at the right end, the front end of the shell 1 is fixedly connected with the feed pipe 11, the upper end of the feed pipe 11 is installed with a sealing cover 111, the lower end of the shell 1 is fixedly connected with the discharge pipe 12, and the valve is installed on the discharge pipe 12 121, the stirring mechanism 2 includes a motor 21, the motor 21 is fixedly connected to the outside of the left end of the housing 1, the right end of the motor 21 is equipped with a first rotating shaft 22, the first rotating shaft 22 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com