Processing device of concrete for mold pouring

A processing device and concrete technology, which are applied in the directions of clay preparation device, cement mixing device, chemical instrument and method, etc., to achieve the effect of improving mixing effect and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

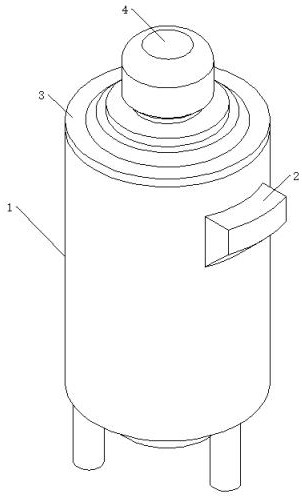

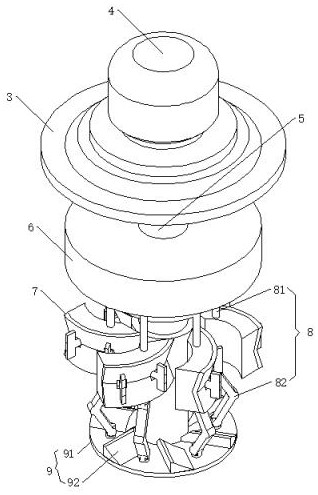

[0031] see Figure 1-6 As shown, the present invention is a processing device for mold pouring concrete, comprising a cylinder 1, the side of the cylinder 1 is provided with a feed port 2 communicating with the inside, and an end cap 3 is installed on the upper port of the cylinder 1 A motor 4 is installed on the end cover 3, the output end of the motor 4 extends into the interior of the cylinder 1, and the output end of the motor 4 is connected to the transmission shaft 5, and the impeller assembly 6, Mixing assembly 7 and chassis 9.

[0032] The rotating motor 4 drives the impeller assembly 6, the mixing assembly 7 and the chassis 9 to rotate synchronously. After the rotating impeller assembly 6, the mixing assembly 7 and the chassis 9 have mixed the concrete raw materials of the cylinder 1, the concrete is poured through the outlet of the cylinder 1. Drain for easy access.

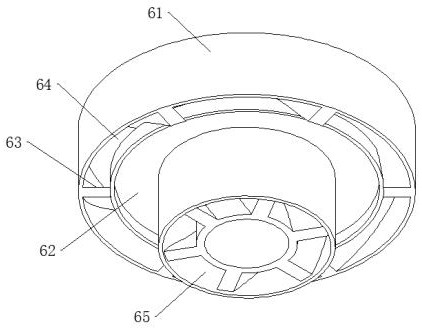

[0033] The impeller assembly 6 includes an outer casing 61, an inner casing 62 and a helical blade...

Embodiment 2

[0045] A method for processing concrete for mold pouring, comprising a processing device, the steps are as follows:

[0046] Step 1: Add the concrete raw materials that need to be mixed into the cylinder body 1 through the feed port 2 provided on the cylinder body 1;

[0047] Step 2, start the motor 4, the motor 4 drives the impeller assembly 6, the mixing assembly 7 and the chassis 9 to rotate through the transmission shaft 5, after the concrete raw materials are mixed, turn off the switch, and discharge the concrete through the outlet provided at the bottom of the cylinder 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com