Gas-liquid rotary turbine separation device

A separation device and gas-liquid technology, applied in the field of gas-liquid rotary turbine separation device, can solve the problems of not being able to ensure efficient utilization of fluid pressure energy, useful energy consumption of multiphase fluids, and reducing secondary mixing, etc. Small, minimizes gas entrainment and liquid carryover, reduces the effect of remixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

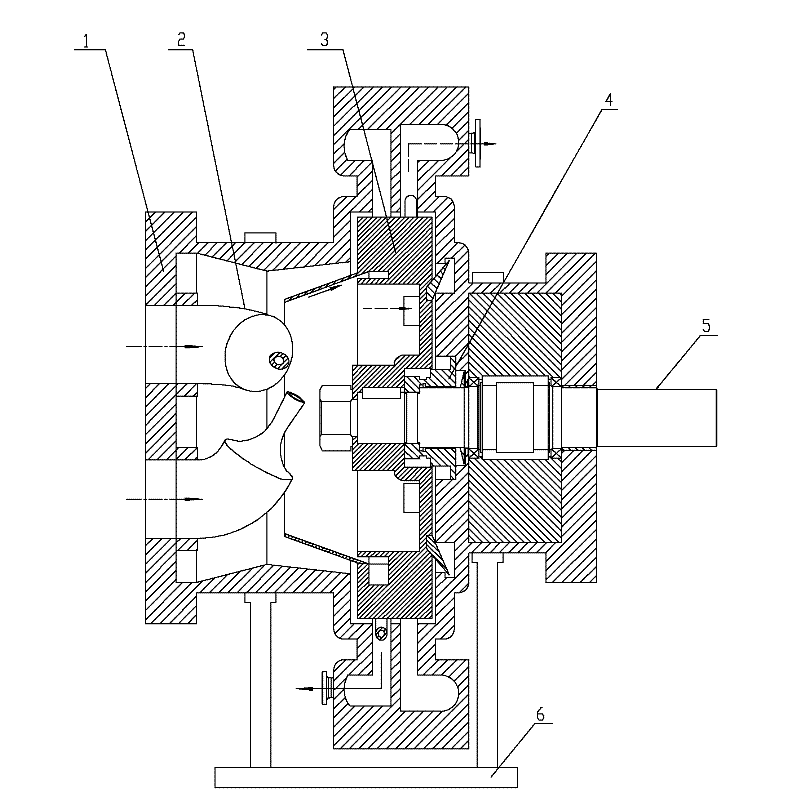

[0026] as attached figure 1 , 5 As shown, the present invention mainly includes a casing 1 as a gas-liquid discharge device, a gas-liquid two-phase nozzle 2, a separation rotor 3, a sealing and lubricating device 4, a separator shaft 5, and a separator support 6. The cavity in the housing 1 is an axially horizontal rotationally symmetrical structure, and the cavity of the housing 1 is provided with a separator shaft 5 fixed in the cavity through a sealing and lubricating device 4 from right to left. 5. One end protrudes from the shell 1, and the other end is fixed with the separation rotor 3 and is located in the middle of the cavity. On the left side of the separation rotor 3, a gas-liquid two-phase nozzle 2 is fixed on the left end of the shell 1. The whole invention is an axial "building block" installation, which is beneficial to the maintenance of the separator and the replacement of parts.

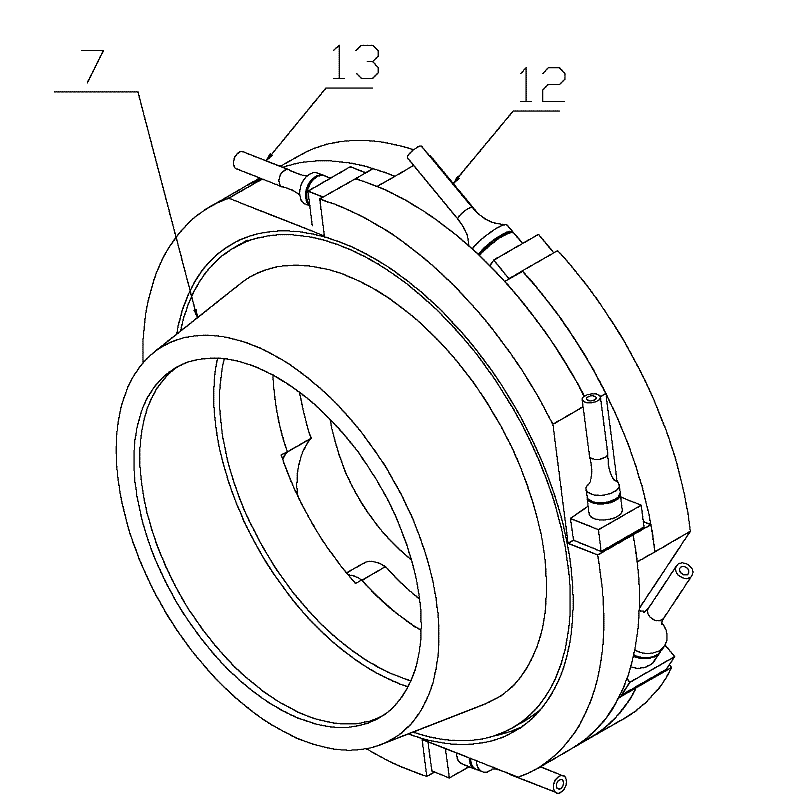

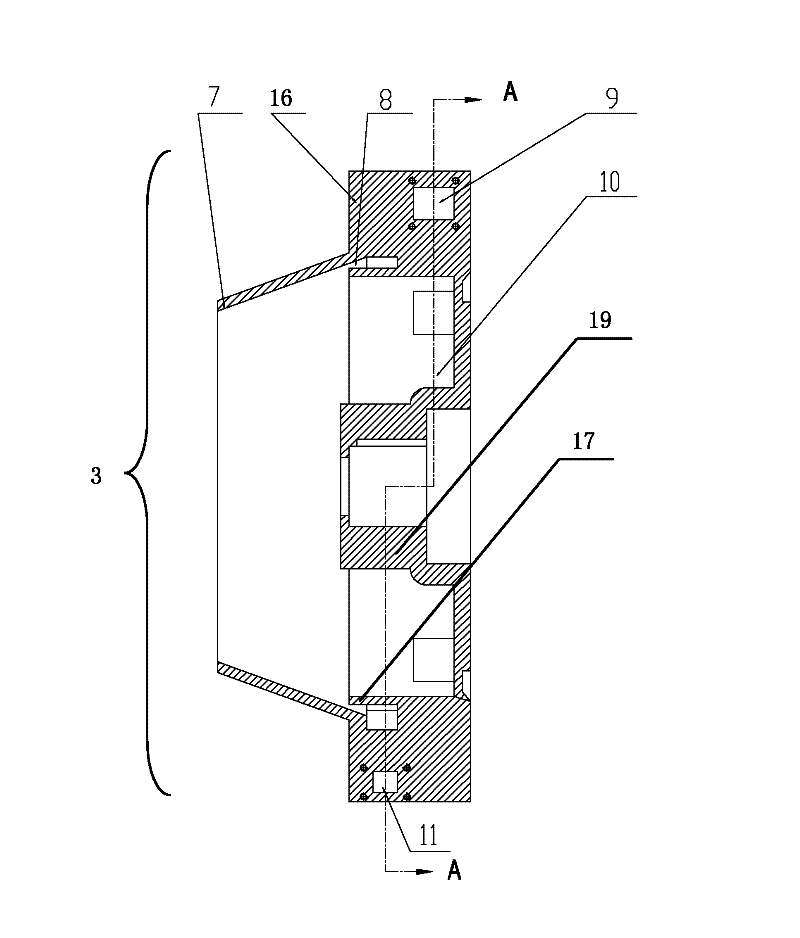

[0027] as attached Figure 2~4 As shown, the separation rotor 3 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com