Method for improving utilization efficiency of gypsum in sulphoaluminate cement

A technology for sulphoaluminate cement and gypsum, which is applied in the field of improving the utilization efficiency of gypsum in sulphoaluminate cement, so as to achieve the effects of reducing the amount of addition, improving the strength of the gel, and suppressing the shrinkage defect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

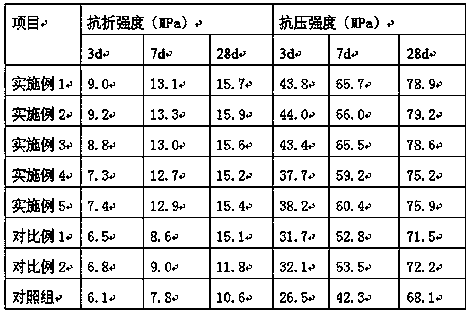

Examples

Embodiment 1

[0020] A method for improving the utilization efficiency of gypsum in sulphoaluminate cement. The natural gypsum is pretreated to improve its activation performance, and then used for the preparation of sulphoaluminate cement clinker and the post-mixing of clinker.

[0021] Specifically, the preparation of sulphoaluminate cement clinker: grind the raw material with a good proportion, grind the powder to pass through a 70-micron sieve, and carry out heating and calcination. The clinker firing process temperature is 1090°C, and heat preservation 20-25 minutes, cooling to obtain sulphoaluminate cement clinker.

[0022] The main components of the sulphoaluminate cement raw meal are calculated by mass percentage: limestone accounts for 48%, bauxite accounts for 27%, pretreated gypsum accounts for 4.5%, and the rest is aluminum ash and a small amount of impurities.

[0023] The limestone used was taken from Limestone Factory in Nanyang, Henan; the bauxite and aluminum ash slag were ...

Embodiment 2

[0029] A method for improving the utilization efficiency of gypsum in sulphoaluminate cement. The natural gypsum is pretreated to improve its activation performance, and then used for the preparation of sulphoaluminate cement clinker and the post-mixing of clinker.

[0030] Specifically, the preparation of sulphoaluminate cement clinker: grind the raw material with a good ratio, grind the powder to pass through a 75 micron sieve, and carry out heating and calcination. After 22 minutes, cool to obtain sulphoaluminate cement clinker.

[0031] The main components of the sulphoaluminate cement raw meal are calculated by mass percentage: limestone accounts for 51%, bauxite accounts for 30%, pretreated gypsum accounts for 5.0%, and the rest is aluminum ash and a small amount of impurities.

[0032] The limestone used was taken from Limestone Factory in Nanyang, Henan; the bauxite and aluminum ash slag were taken from Guiyang Fangcheng Mining Co., Ltd.

[0033] Wherein, the preparat...

Embodiment 3

[0038] A method for improving the utilization efficiency of gypsum in sulphoaluminate cement. The natural gypsum is pretreated to improve its activation performance, and then used for the preparation of sulphoaluminate cement clinker and the post-mixing of clinker.

[0039] Specifically, the preparation of sulphoaluminate cement clinker: grind the raw material with a good proportion, grind the powder to pass through a 80-micron sieve, and carry out heating and calcination. The clinker firing process temperature is 1100 ° C, and heat preservation After 25 minutes, cool to obtain sulphoaluminate cement clinker.

[0040] The main components of the sulphoaluminate cement raw meal are calculated by mass percentage: limestone accounts for 54%, bauxite accounts for 33%, pretreated gypsum accounts for 5.5%, and the rest is aluminum ash and a small amount of impurities.

[0041] The limestone used was taken from Limestone Factory in Nanyang, Henan; the bauxite and aluminum ash slag wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com