Isolating method for hot isostatic pressing diffusion welding

A hot isostatic pressing diffusion and special-shaped technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as welding defects, unusable isolation materials, and fragility, so as to improve quality, eliminate welding defects, Realize the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

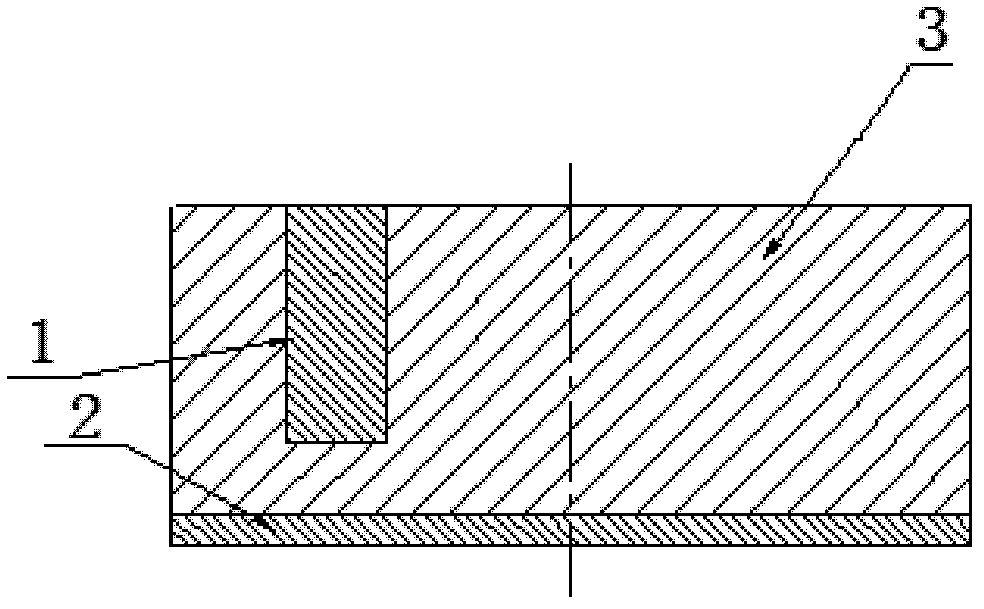

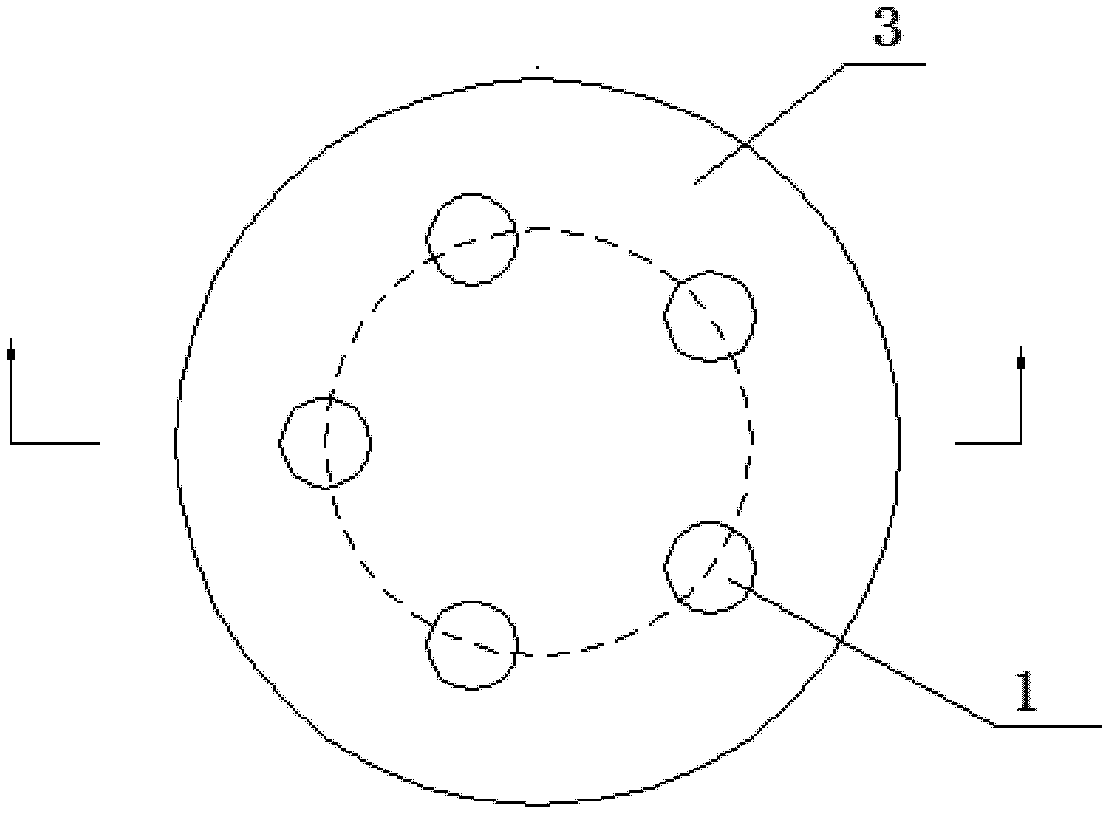

[0020] Such as figure 1 with figure 2 As shown, the special-shaped copper-steel bimetal assembly to be welded is composed of a steel cylinder 3, five copper cylinders 1 and a copper plate 2. Among them, there are 5 cylindrical grooves along the circumference in the steel cylinder 3, and the 5 copper cylinders 1 are respectively placed in the 5 grooves of the steel cylinder 3, and the steel cylinder 3 is placed on the copper plate 2 that matches its shape. .

[0021] The concrete steps of a kind of isolation method of hot isostatic pressure diffusion welding described in the present invention are as follows:

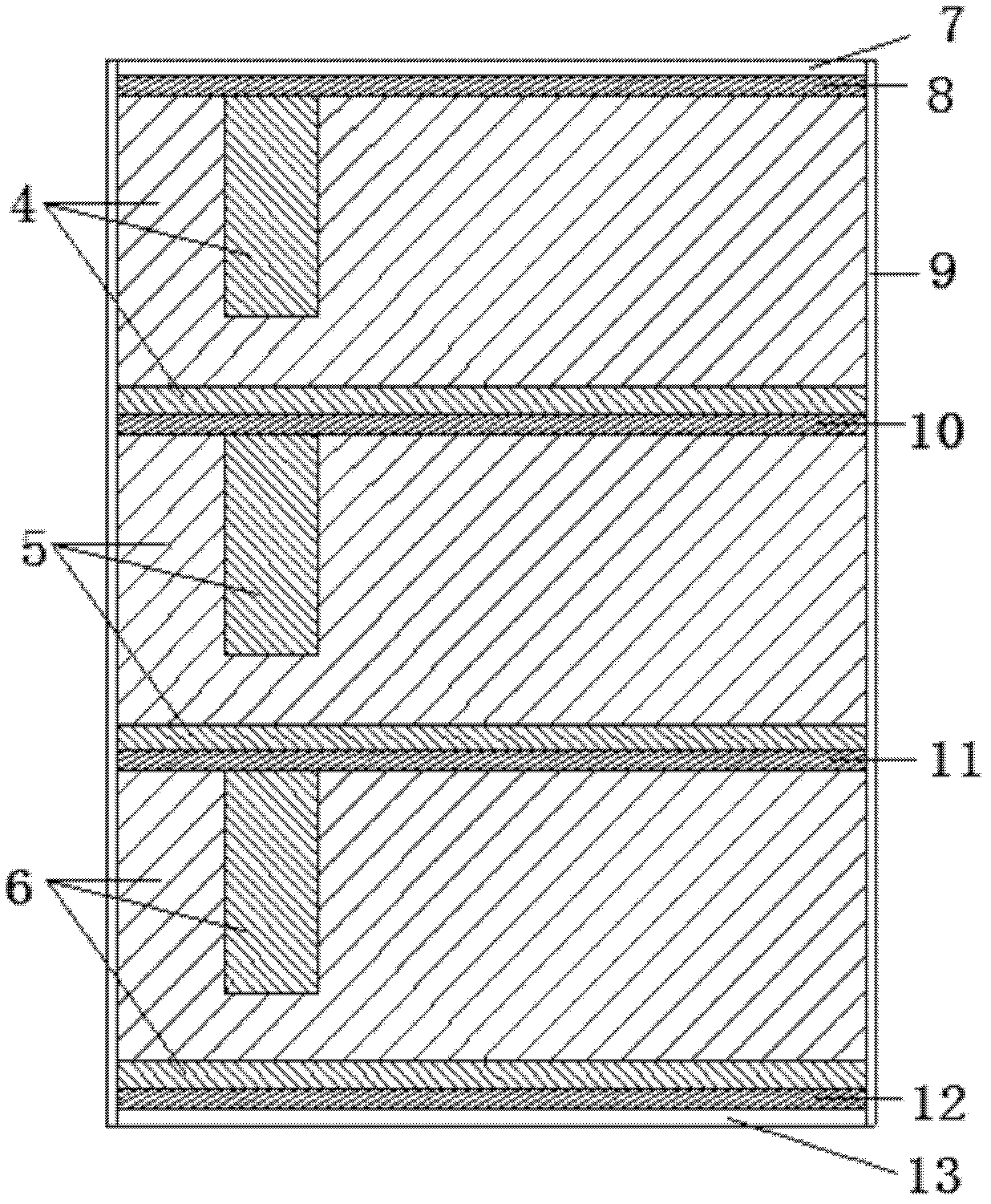

[0022] (1) if image 3 As shown, the first special-shaped structure copper-steel bimetallic assembly 4, the second special-shaped structure copper-steel bimetallic assembly 5 and the third special-shaped structure copper-steel bimetallic assembly 6 are stacked up and down in the sheath 9, and in An oxidized stainless steel sheet 2 10 is set between the first special-...

Embodiment 2

[0028] Such as Figure 4 As shown, the special-shaped copper-steel bimetal assembly to be welded is composed of a steel cylinder 3 and five copper cylinders 1 . Among them, five cylindrical grooves are formed along the circumference in the steel cylinder 3 , and the five copper cylinders 1 are respectively placed in the five grooves of the steel cylinder 3 .

[0029] The concrete steps of a kind of isolation method of hot isostatic pressure diffusion welding described in the present invention are as follows:

[0030] (1) if Figure 5 As shown, four special-shaped structure copper-steel bimetal assemblies are stacked up and down in the sheath 9, and a copper-steel bimetal assembly with special-shaped structure is set between the first special-shaped structure copper-steel bimetal assembly and the second special-shaped structure copper-steel bimetal assembly. Layer-isolated oxidized stainless steel sheet 2 10; a layer of isolated oxidized stainless steel sheet 3 is set between...

Embodiment 3

[0036] The difference with Example 1 is:

[0037] The special-shaped structure bimetal assembly to be welded is a special-shaped structure titanium-steel bimetal assembly.

[0038] The heat treatment method is to oxidize the stainless steel sheet. Put the cleaned and dried stainless steel sheet into a heating furnace, keep it at 700°C for 1 hour, and cool down with the furnace to obtain a stainless steel sheet with a stable oxide film on the surface.

[0039] The material of the stainless steel sheet is Cr12, and the thickness is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com