Double-sealing mechanical type bleeding valve for gas holder

A double-sealing, mechanical technology, used in mechanical equipment, safety valves, balance valves, etc., can solve the problems of insufficient pressing force of the sealing ring, low reliability of sealing performance, gas leakage, etc. Good performance and the effect of preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

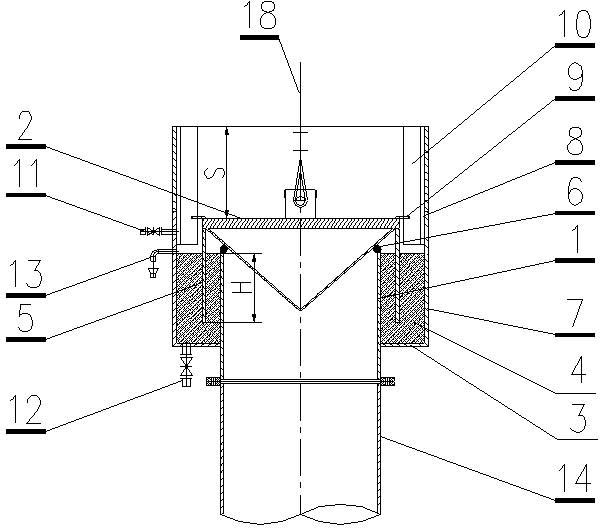

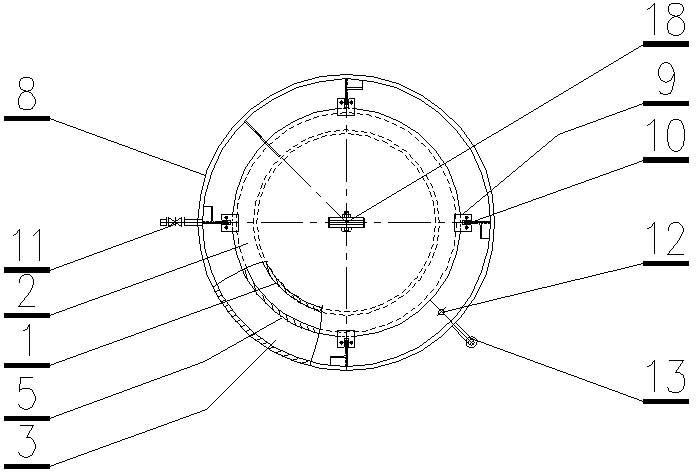

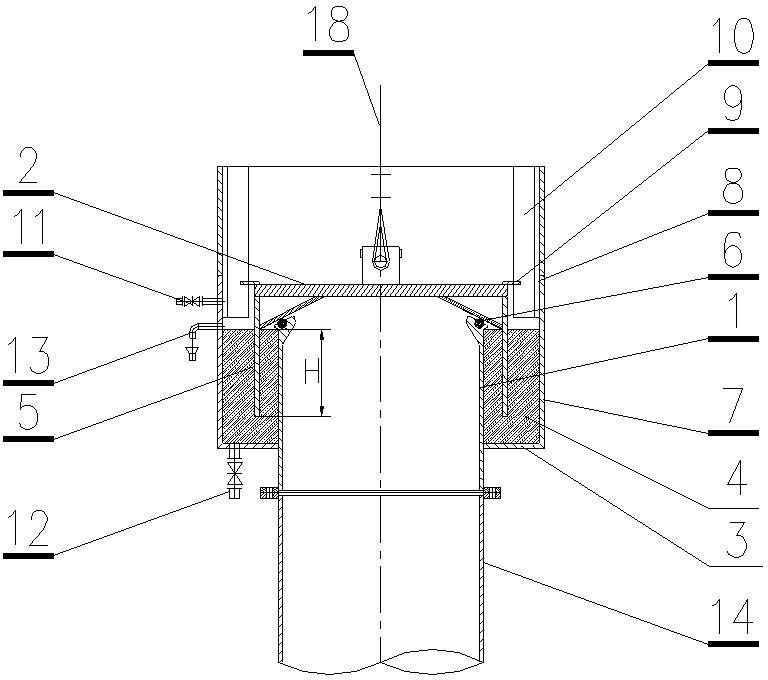

[0030] Such as figure 1 Shown is the structural representation of the first embodiment of the double-sealed mechanical relief valve for the gas tank of the present invention, figure 2 for figure 1 The top view of the double-sealed mechanical relief valve for gas tanks in this embodiment includes a soft seal arranged between the valve seat 1 and the valve cover 2 and a guide rail for limiting the switching movement of the valve cover 2. The valve seat 1 is provided with a ring The outer wall of the valve seat 1 has a circle and is used to contain the water seal groove 3 of the sealing liquid 4. The valve cover 2 is provided with a skirt 5 that matches the water seal groove 3 and extends downward. The skirt 5 is on the valve cover 2 When it is closed, it is inserted under the liquid surface of the water seal tank 3 to form a water seal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com