Liquid crystal display panel

一种液晶显示面板、阵列基板的技术,应用在静态指示器、仪器、非线性光学等方向,能够解决显示不良、产能下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

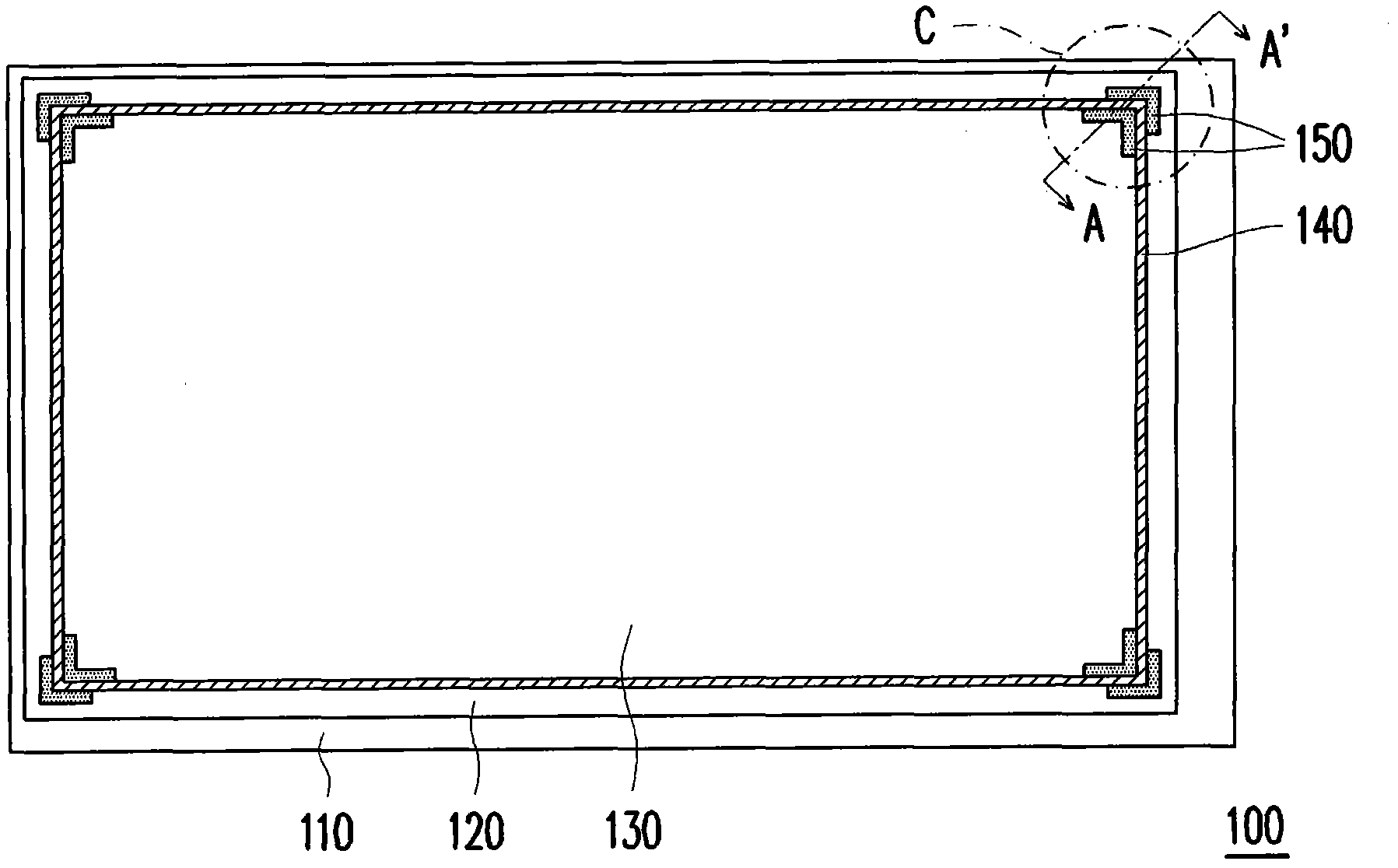

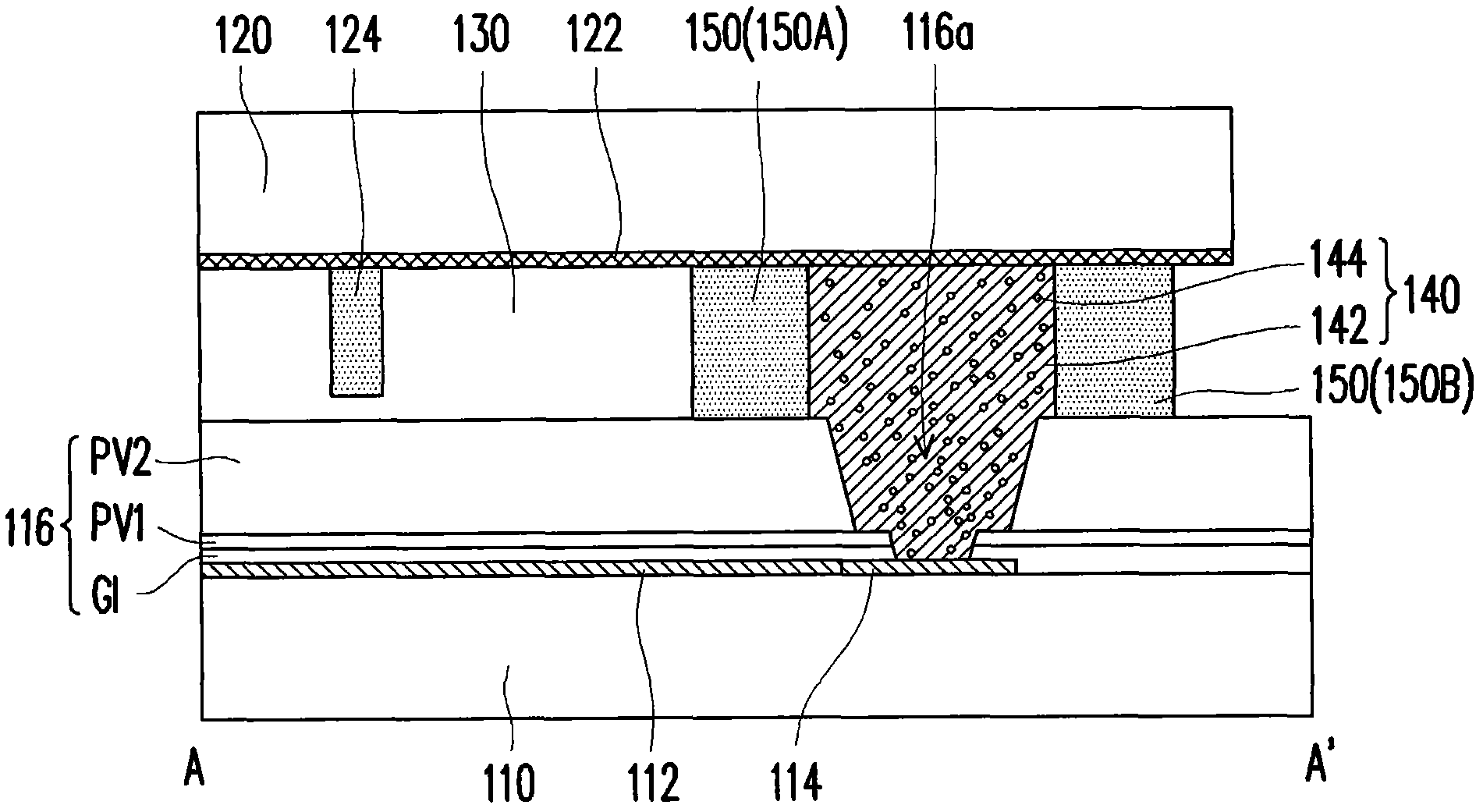

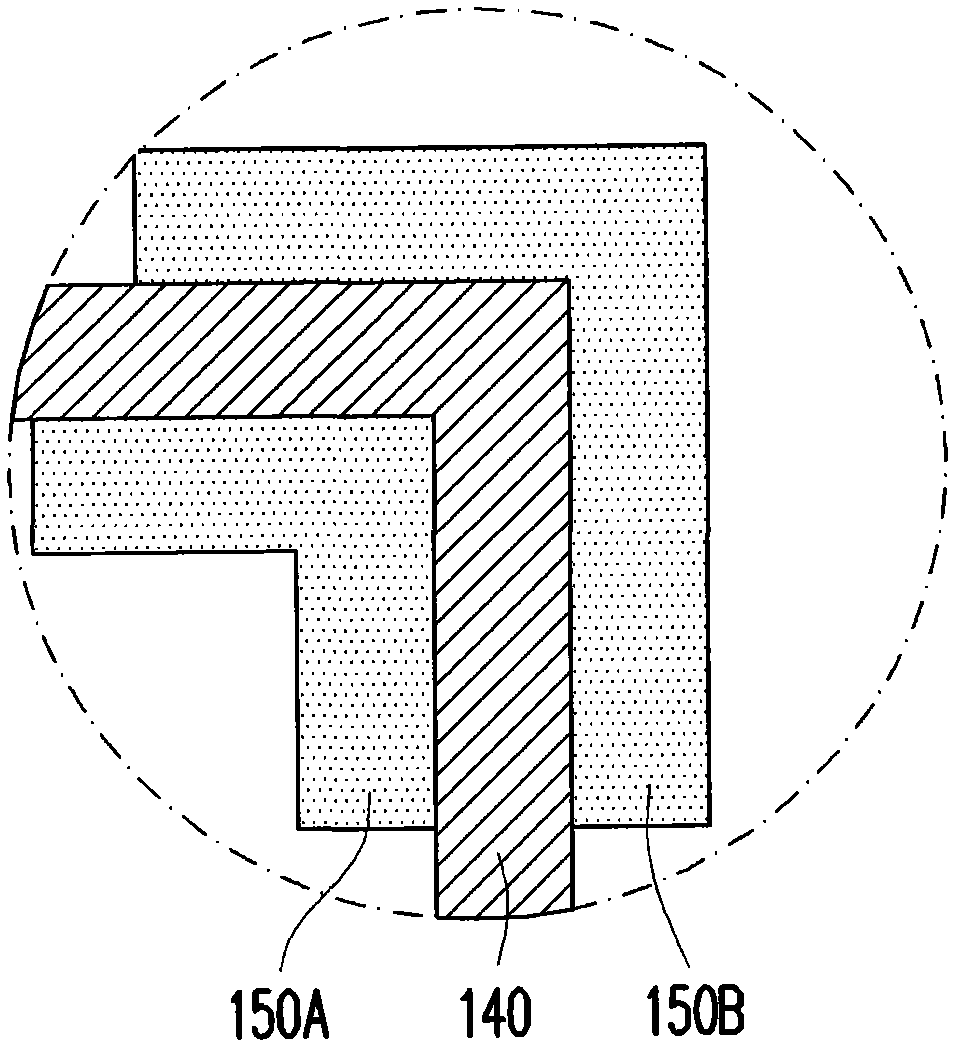

[0049] figure 1 is a schematic top view of a liquid crystal display panel according to an embodiment of the present application, and figure 2 for figure 1 Schematic sectional view along section line A-A' at middle corner C. Please refer to figure 1 and figure 2 The liquid crystal display panel 100 of this embodiment includes an active element array substrate 110 , a facing substrate 120 , a liquid crystal layer 130 , a conductive sealant 140 and a plurality of position-limiting structures 150 . The active element array substrate 110 has a plurality of common lines 112, a plurality of transfer pads 114 and a dielectric layer 116, the transfer pads 114 are electrically connected to the common lines 112, and the dielectric layer 116 has a plurality of openings 116a to expose the transfer pad 114 . The opposite substrate 120 has a common electrode 122 , and the liquid crystal layer 130 is disposed between the active device array substrate 110 and the opposite substrate 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com