Infrared database intelligent diagnosis management system for charged equipment

A technology of intelligent diagnosis and live equipment, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as wrong suggestions, lack of professional system training for infrared detection, low level of equipment application, etc., to achieve the effect of convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

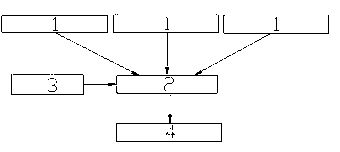

[0048] Infrared database intelligent diagnosis and management system for live equipment, see appendix Figure 1-2 , which includes: at least one substation operation platform 1 set in the grass-roots substation, intelligent data diagnosis and processing center 2, middle-level infrared dedicated engineer operation platform 3, and provincial / municipal high-level query and monitoring platform 4.

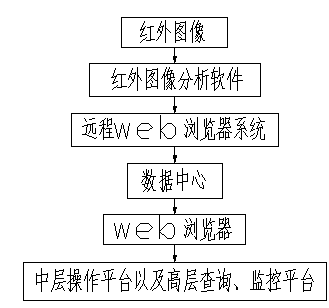

[0049] The substation operation platform 1 is provided with an infrared image analysis software system and a remote WEB browser system. The infrared image analysis software system has built-in infrared image analysis software with infrared image analysis function and infrared video analysis software with infrared video analysis function.

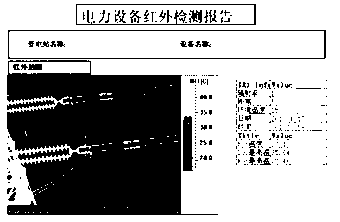

[0050] Infrared image analysis software uses EXCEL REPORT analysis software with powerful analysis functions to analyze the captured infrared images, and then quickly generates an infrared report including defect level, inspection time, line na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com