Gear double-tooth error measuring system

An error measurement and gear technology, which is applied in the field of gear double mesh error measurement system, can solve the problems of inability to observe the error curve, error analysis, and inability to achieve the effects of improving detection accuracy and efficiency, fast sampling speed, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

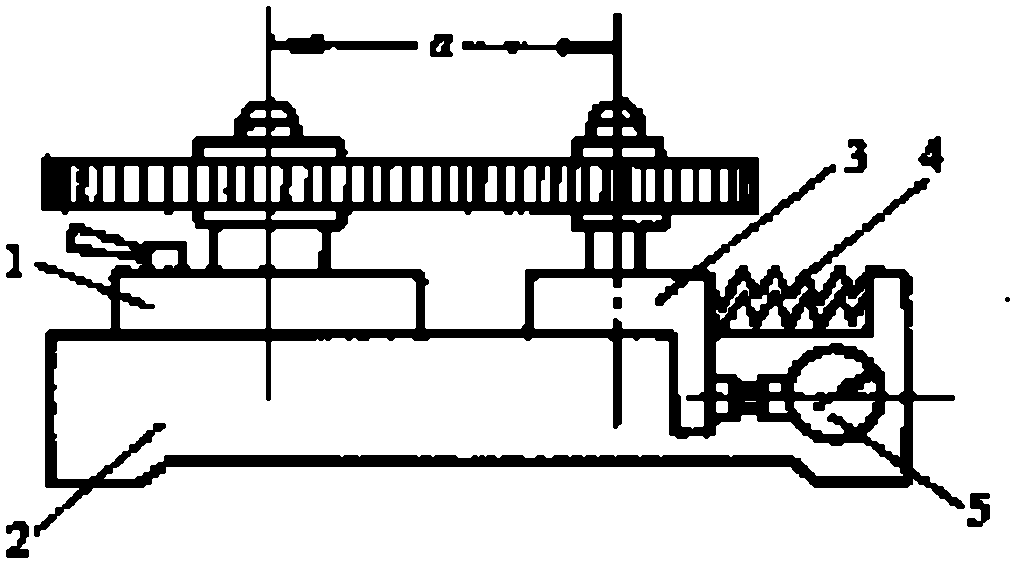

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

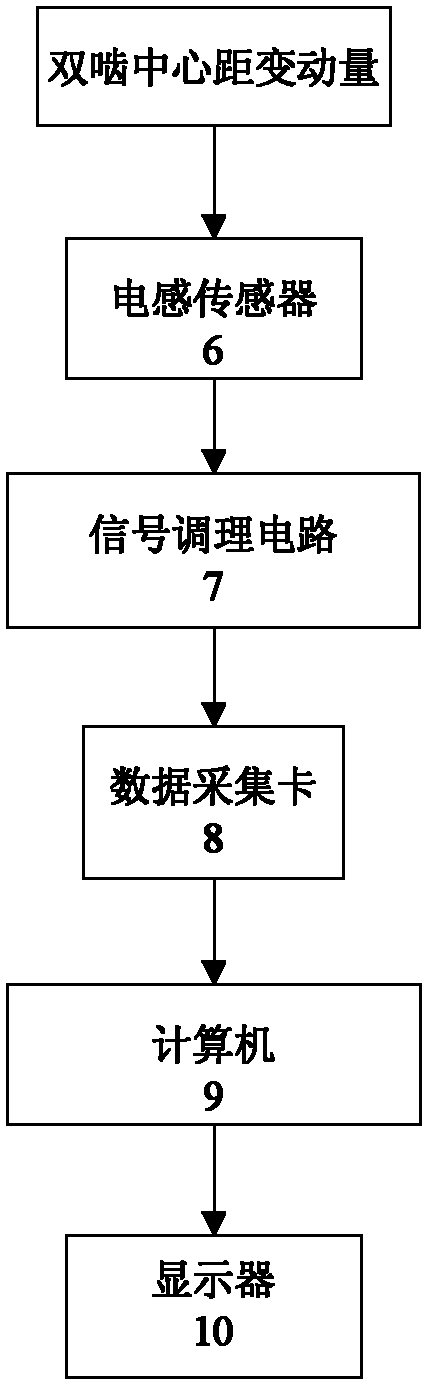

[0023] Such as figure 2 As shown, a gear double-mesh error measurement system includes an inductance sensor 6, a signal conditioning circuit 7, a data acquisition card 8, a computer 9 and a display 10 connected in sequence. The sensor 6 is located at the position of the dial indicator of the original traditional gear double meshing instrument.

[0024] In this embodiment, the inductance sensor 6 adopts a differential inductance sensor (LVDT) produced by Analog Devices Corporation of the United States, the signal conditioning circuit 7 is an AD698 signal conditioning circuit, and the data acquisition card 8 is a data acquisition system developed by National Instruments (NI) of the United States. Card, computer 9 is the computer equipped with the integrated program Labview development platform based on the "graphics" mode launched by NI; AD69...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com