Device for loading and unloading freeze drying system

A drying system and equipment technology, applied in lighting and heating equipment, drying solid materials, dry cargo handling, etc., can solve complex and difficult-to-clean structures and other problems, achieve the effect of saving wires and improving the stability of vertical placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

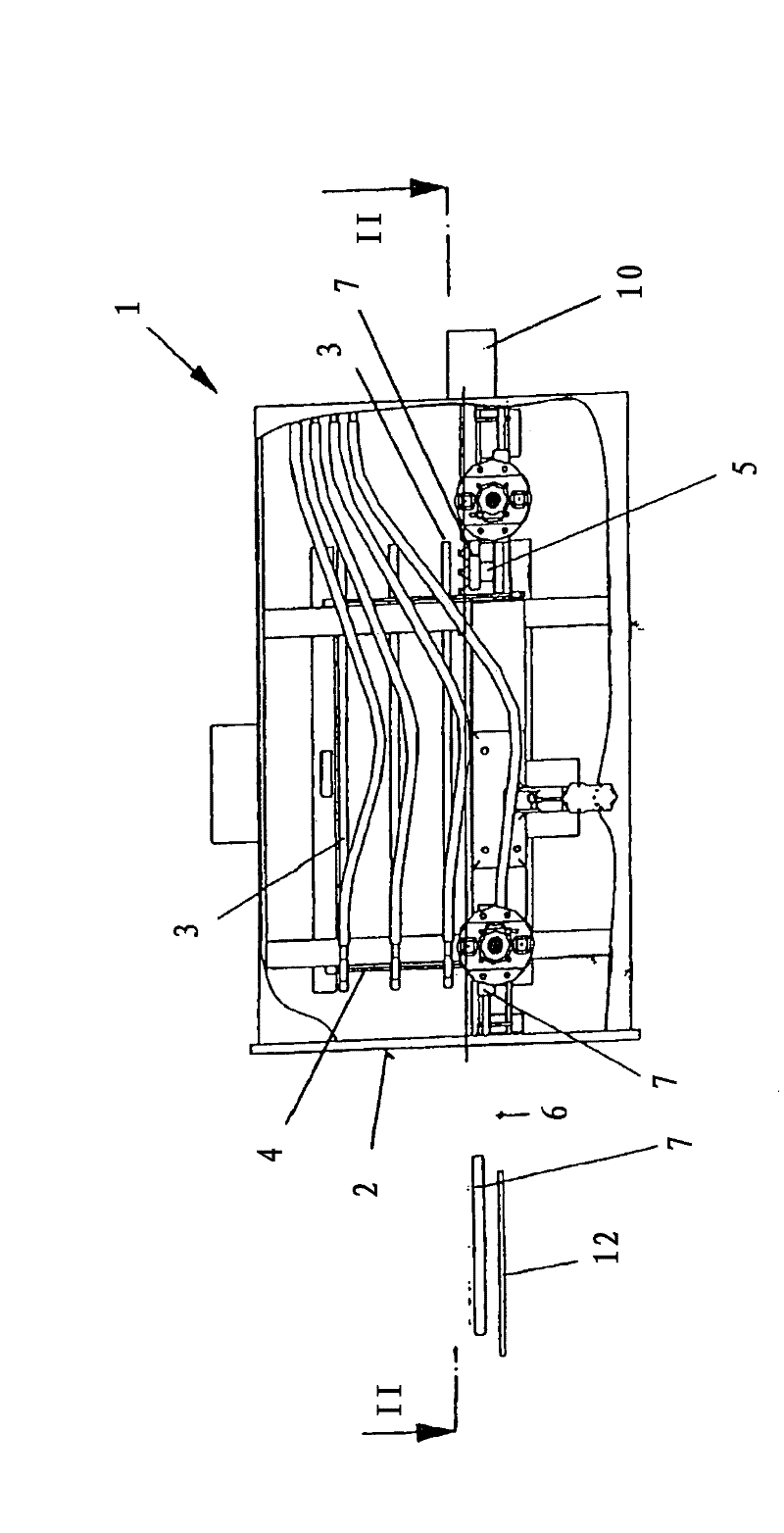

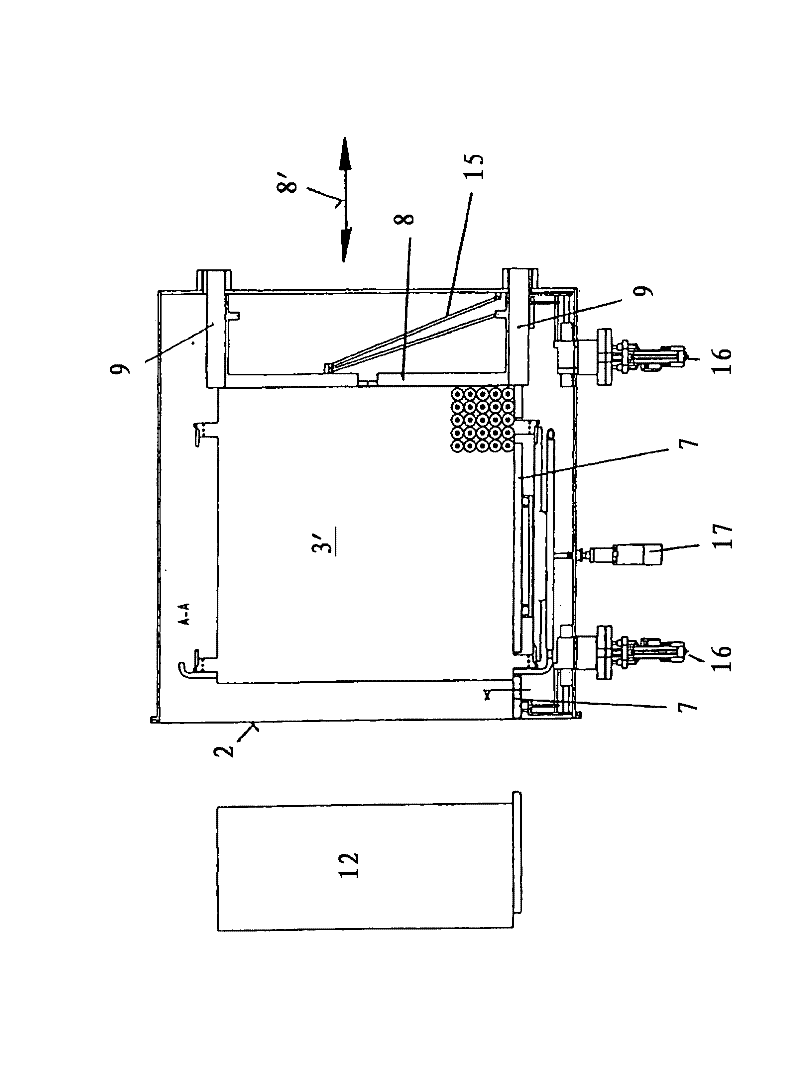

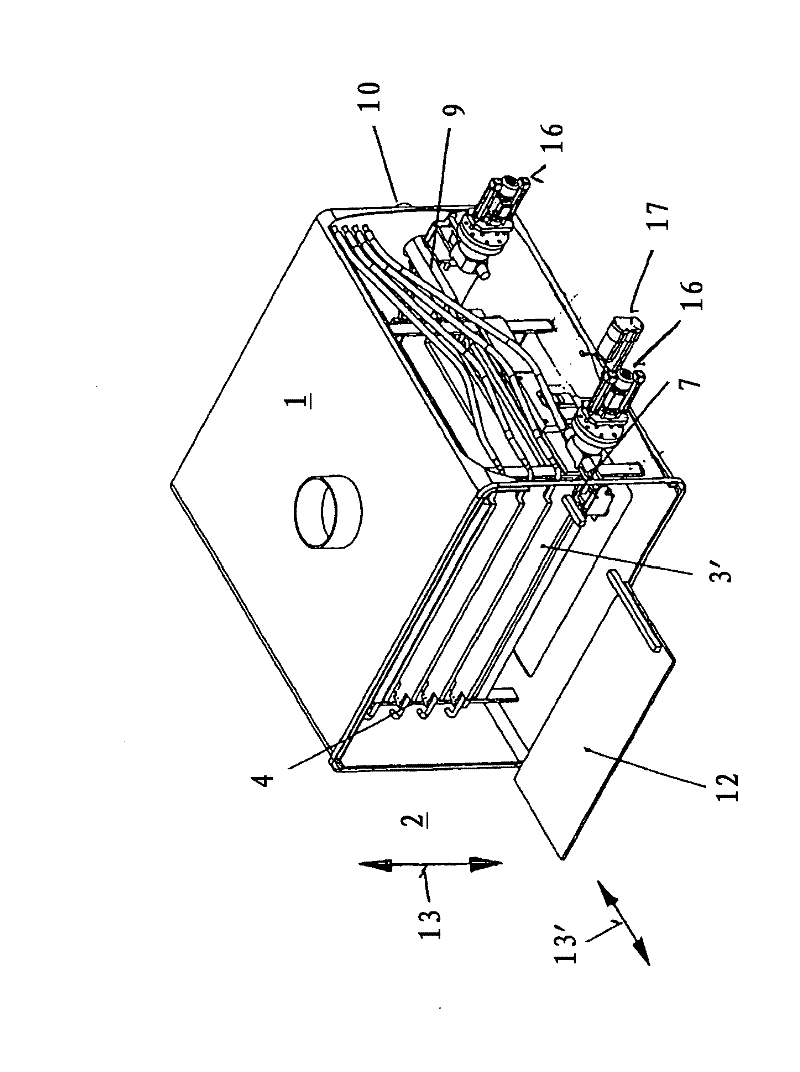

[0039] figure 1 A sectional view is shown of a drying chamber 1 of a freeze-drying system, on the front side 2 of which a closable opening for loading or unloading drying containers 5, not shown with reference numerals, is located. The drying chamber 1 is connected to the condensation chamber in a manner known per se, but this will not be discussed in more detail here.

[0040] Inside the drying chamber 1 is the arrangement of the placement surfaces 3 which are held vertically displaceable in the holder 4 in a manner known per se. The placing surface 3 is used for placing the drying containers 5 , which each contain dry substances, which will be removed from the drying chamber 1 after the drying process has ended. The height position of the placement surface 3' here is indicated by reference numeral 6, which corresponds to the unloading position of the placement surface. It is important that the vertical adjustability of all resting surfaces 3 of the stand 4 is set such that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com