Automobile hydraulic cylinder setter

A technology of hydraulic sub-cylinders and setters, applied in hand-held tools, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive resetting of sub-cylinders, unsafe, affecting the braking return, etc., to achieve social benefits and have operational advantages interactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below by specific embodiment:

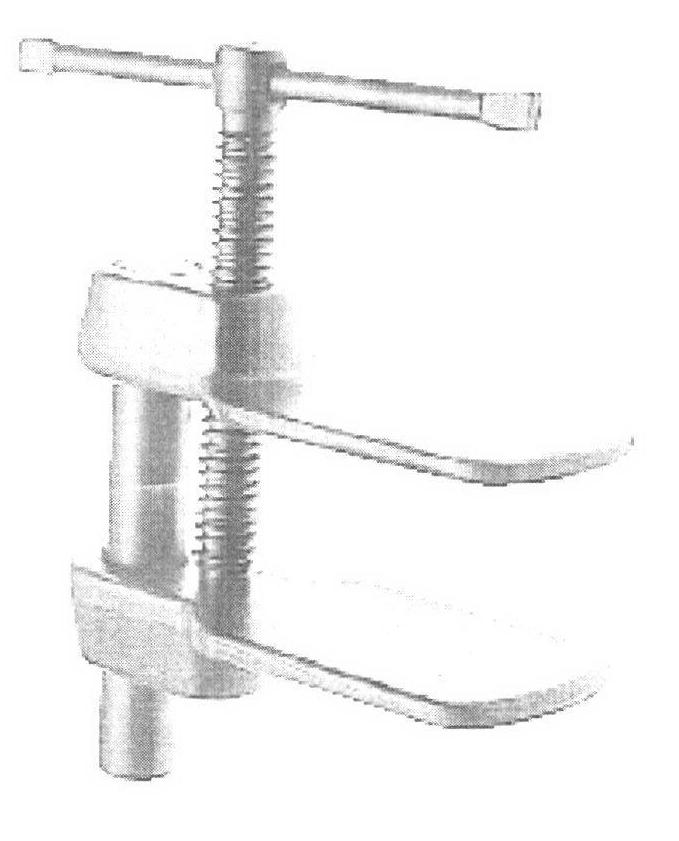

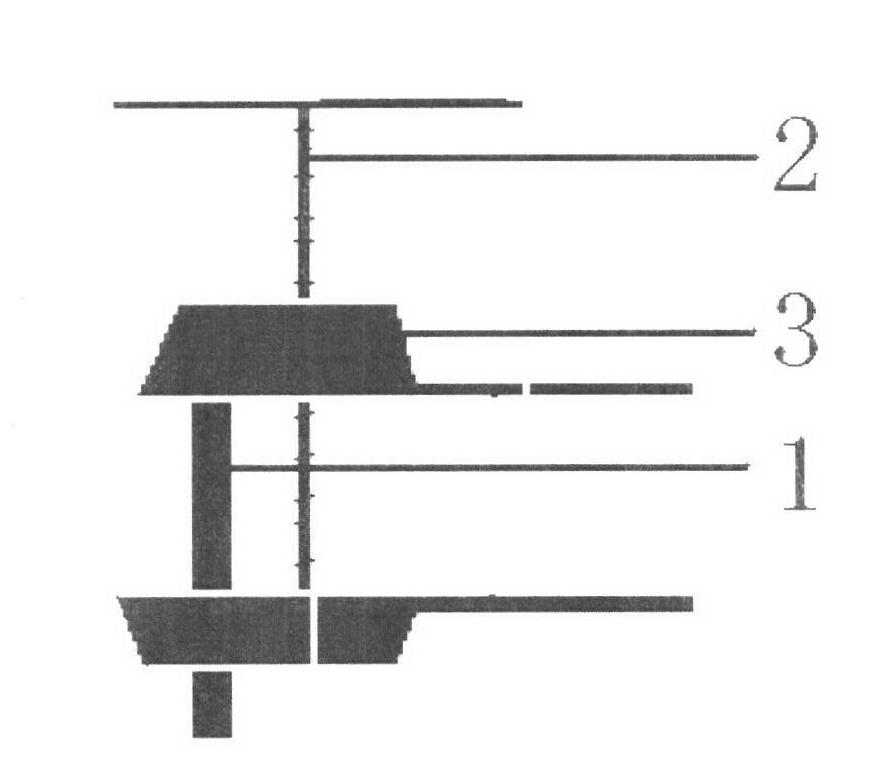

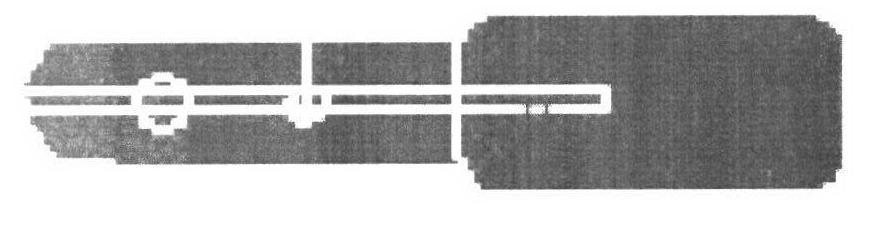

[0012] The invention includes a round bar 1, which is connected with trapezoidal threads 2 and modules 3 to form a parallelogram. In actual use, after the cylinder piston is cleaned, apply brake fluid and place it in the cylinder body. The setter is placed inside the bracket of the cylinder cylinder. The trapezoidal thread rotates clockwise to expand the module outward and press the piston so that reset. When a single sub-cylinder piston is to be removed from the outside, use a movable fixture to clamp the dust-proof sleeve groove of the sub-pump piston, put on the module connecting hook, place the fixer on the outside of the brake sub-cylinder bracket, rotate the trapezoidal thread counterclockwise, and pull The inner piston of the sub-pump can be easily operated by one person, saving time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com