External combined induction coil array structure for injection moulding and application thereof

A technology of induction coil and array structure, which is applied in the field of external combined induction coil array structure, and can solve the problems of lack of universality and local adjustment of external induction coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

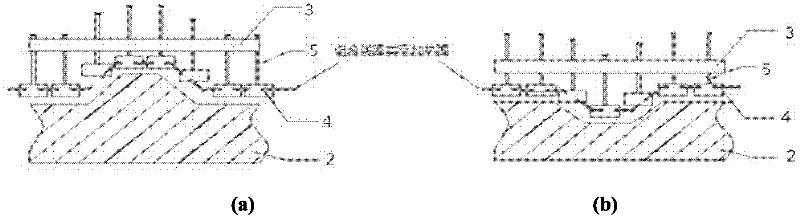

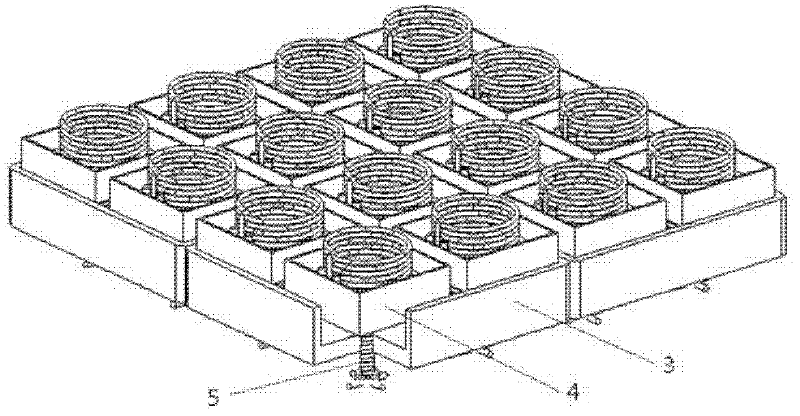

[0029] Such as image 3 As shown, the device includes: a coil overall frame 3 and several induction coil units 4 that are movably connected with it by corresponding adjusting bolts 5 .

[0030] The adjustment bolt 5 is provided with a knob 9 to fix the vertical distance between the induction coil unit 4 and the overall coil frame 3 .

[0031] The induction coil unit 4 includes: an adjusting bolt 5, an electric heating coil 6, a bayonet pin 7, a power connection line 8, a knob 9 and a base 10, wherein: the two ends of the electric heating coil 6 arranged on the front of the base 10 are respectively located at two The power connecting wire 8 arranged on the back of the base 10 is connected to each other, and the detent 7 is arranged on the back of the base 10 and connected to the adjusting bolt 5 .

[0032] Such as Figure 5 As shown, in this embodiment, heat treatment is performed by setting on a manipulator system, which includes: a moving module 12 , a fixed module 13 , a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com