Large-scale desulphurization stirring paddle

A technology of stirring paddles and paddles, which is applied in the direction of mixer accessories, dissolving machines, mixers, etc., can solve the problems of transportation and installation difficulties, large volume, rubber damage, etc., and achieve the effect of convenient transportation and installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

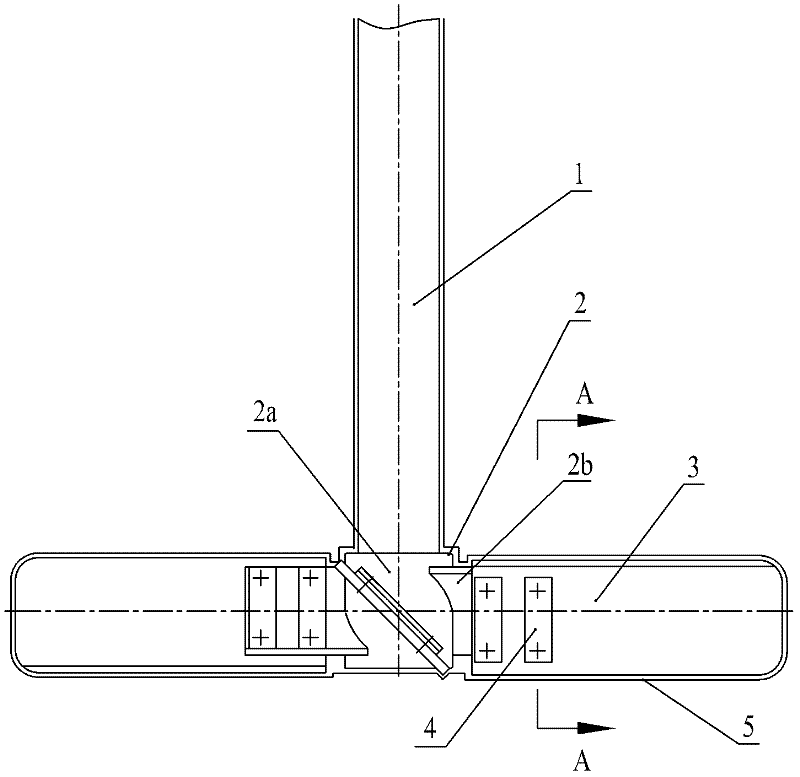

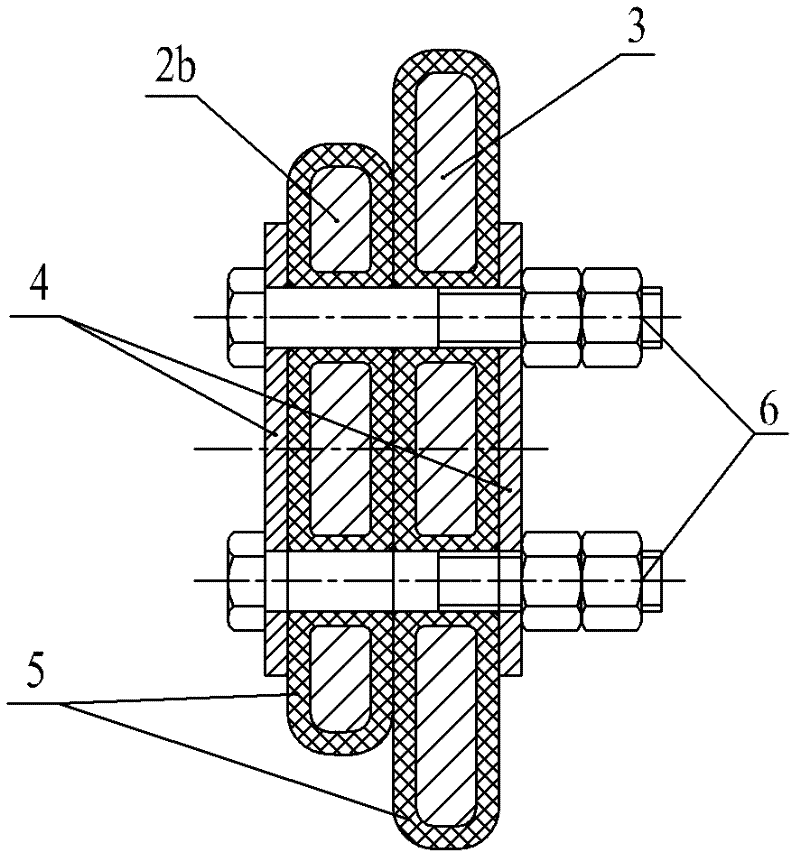

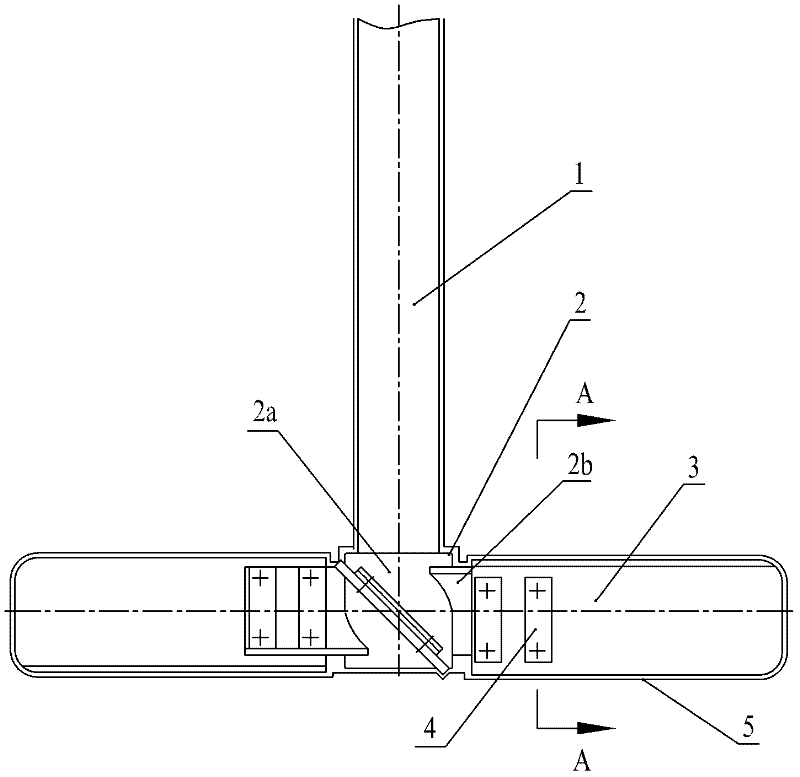

[0014] As shown in the figure: the large desulfurization stirring impeller is mainly composed of three parts: the stirring shaft 1, the hub 2 and the stirring blade 3. The hub 2 includes the hub bushing 2a, and the stirring shaft 1 is welded and fixed on the hub bushing 2a Inside, four short hub paddles 2b uniformly distributed in the circumferential direction are integrally arranged on the periphery of the hub sleeve 2a, and mounting holes are drilled on the hub short paddles 2b. The stirring shaft 1, the hub sleeve 2a and the short hub paddles The surface of 2b is lined with an integrated rubber coating layer 5; the stirring blade 3 is also drilled with a mounting hole, and the surface of the stirring blade 3 is lined with a rubber coating layer 5; the stirring blade 3 and the hub short paddle The leaves 2b are attached and secured by bolt members 6 passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com