Capsule operating mechanism of tyre vulcanizer

A technology of tire vulcanization and manipulation mechanism, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of difficult maintenance and complex structure, and achieve the effect of compact and optimized structure, easy maintenance, installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

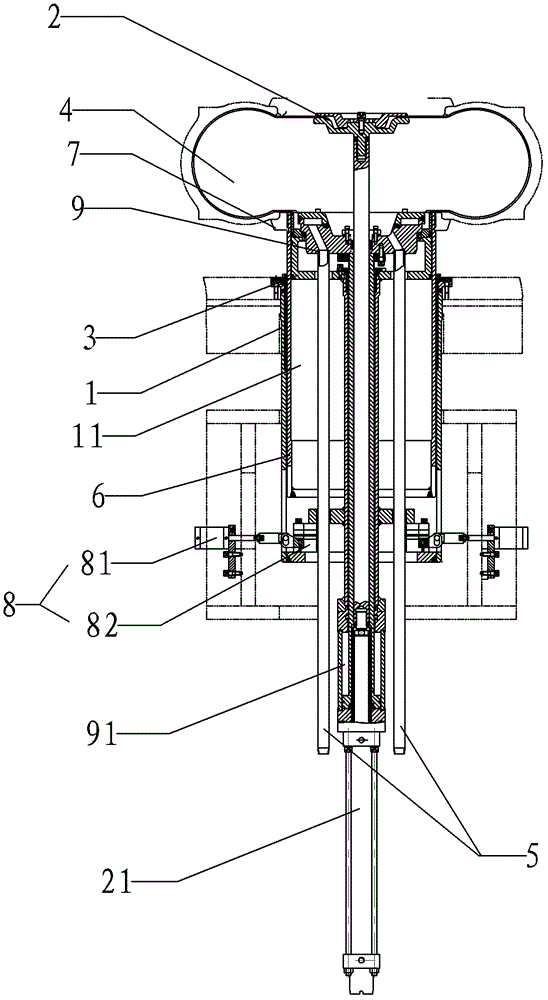

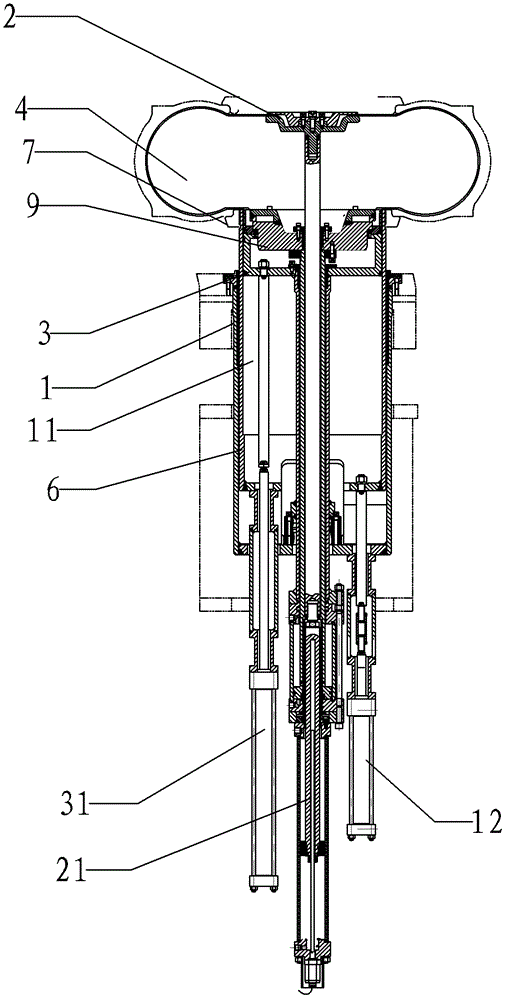

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0027] The present invention provides an embodiment of a bladder operating mechanism of a tire vulcanizing machine, including a bladder 4, a bladder 1, an upper clamp ring 2, a lower clamp ring 3 and a steam conduit 5;

[0028] Described capsule tube 1 is provided with the accommodating space 11 that accommodates capsule 4, and its top surface is provided with the opening that communicates with accommodating space 11, and described upper clamping ring 2 fixes the upper end of capsule 4, and lower clamping ring 3 fixes capsule 4 The lower end of the steam conduit 5 communicates with the capsule 4;

[0029] Before use: the capsule 4 shrinks into the accommodation space 11 in the capsule tube 1;

[0030] When in use: the upper clamp ring 2 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com