Oil pump bracket assembly

A bracket assembly and oil pump technology, which is applied to engine components, liquid fuel feeders, machines/engines, etc., can solve problems such as poor robustness of the fixed form, difficult pressure control, component prolapse, etc., and achieve compact structure, optimization, and improved Vibration reduction effect, reliable and stable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

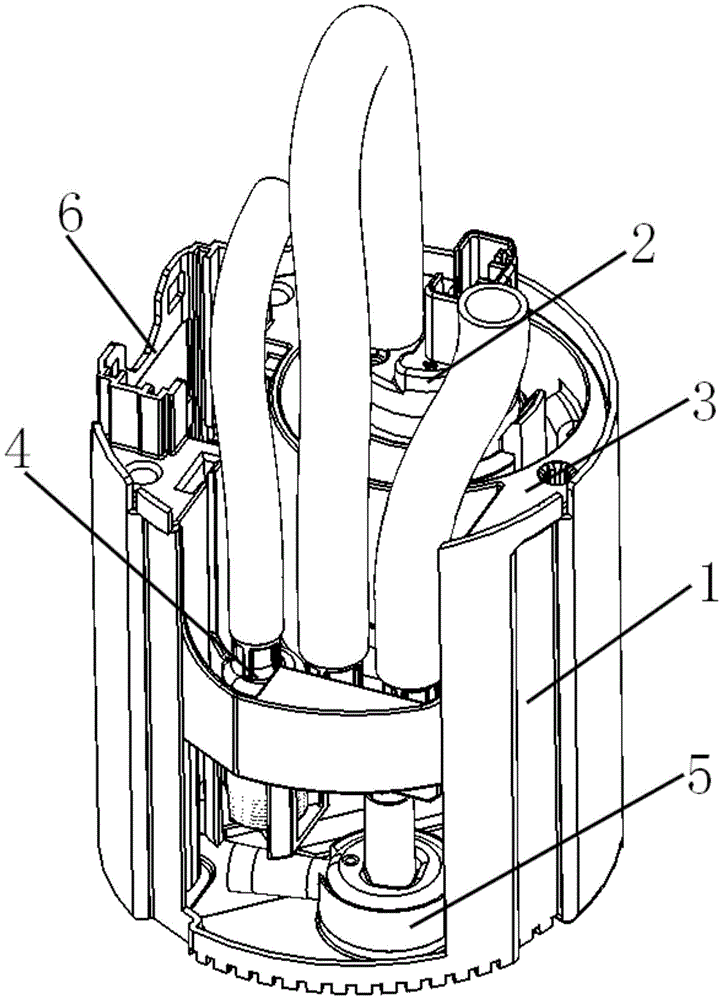

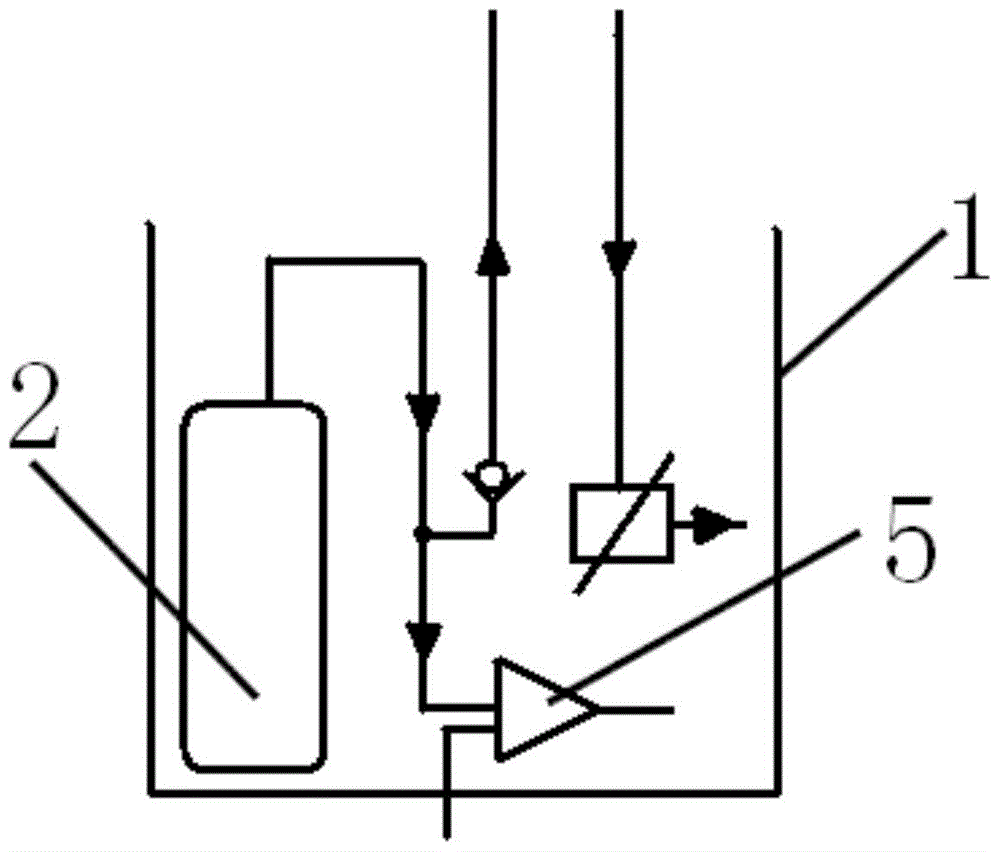

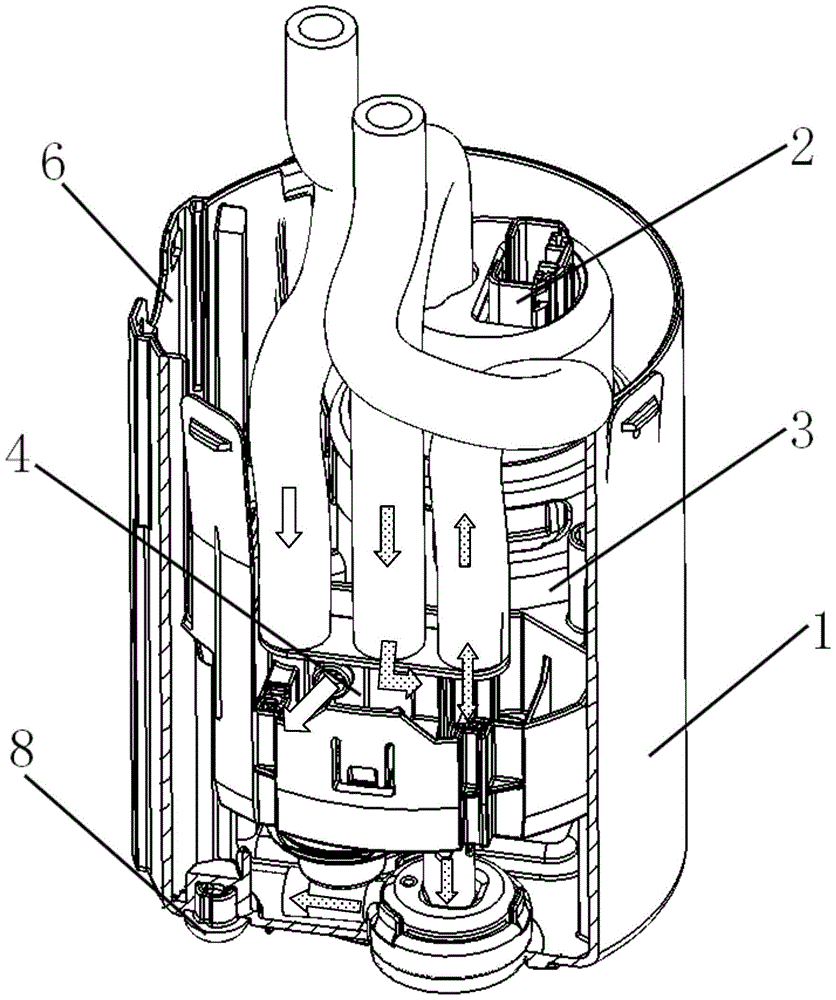

[0062] Oil pump bracket assembly of the present invention, as image 3 As shown, it includes an oil pump 2 located in an oil storage barrel 1, a guide rod 9 (not shown), a pressure regulating valve 10 and a collar 11 (not shown), a pressure regulating valve seat and a pipe joint assembly 4, and an oil pump bracket 3. Actively drive the injection pump 5, the sensor mounting seat 6, etc. In addition, the flow direction of the fuel in the oil circuit is involved image 3 and Figure 10 In , one type of arrow without a filling pattern indicates the oil return flow direction, and two kinds of arrows with a filling pattern indicate the oil outlet flow direction of the fuel pump and the fuel flow direction of the active return injection pump.

[0063] The following will refer to Figure 4 to Figure 13 Describe the structure and interconne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com