Mounting method for air delivery duct of conference room of special railway vehicle

A special vehicle and installation method technology, which is applied in the heating/cooling of railway vehicles, railway car body parts, locomotives, etc., can solve the problems of high noise and inability to meet the use requirements of conference rooms, and achieve noise reduction, simplified design concepts, The effect of improving human comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

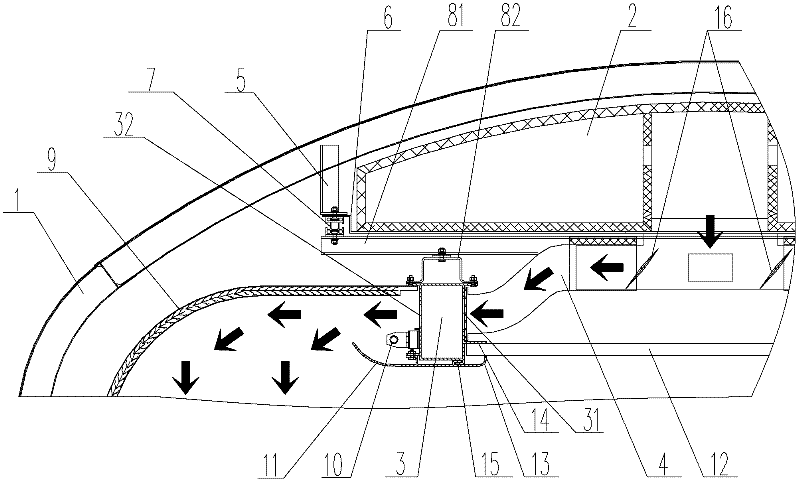

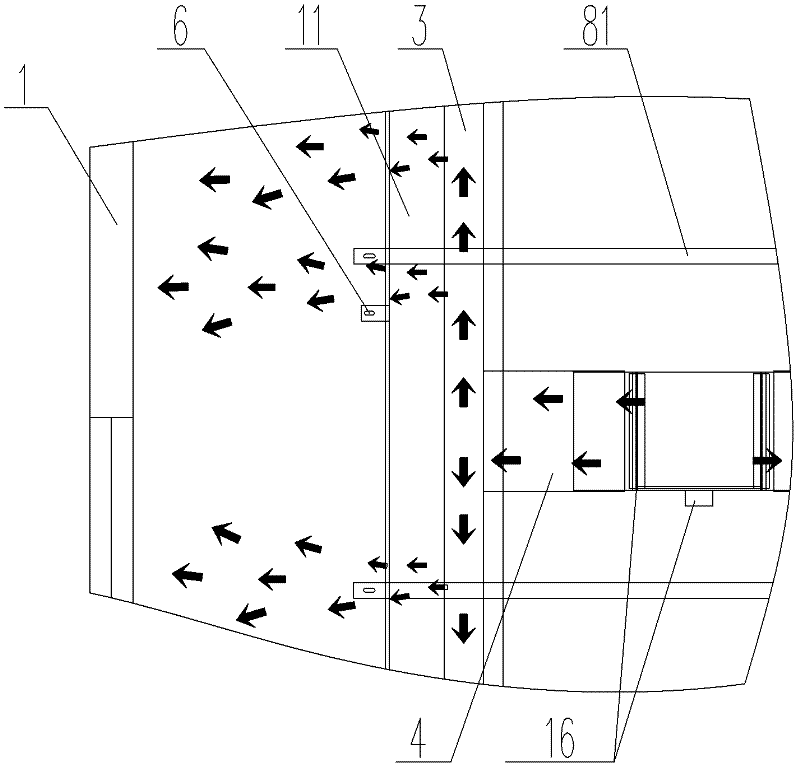

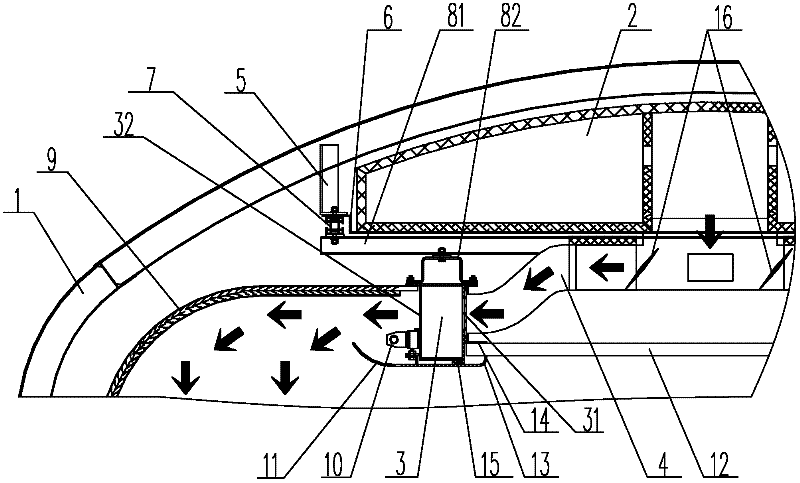

[0015] The air supply channel of the railway special vehicle meeting room involved in this embodiment, such as figure 1 , figure 2 As shown, the composition includes: the main air duct 2 hoisted on the roof steel structure 1, the secondary air duct 3 hoisted below the main air duct 2 and arranged longitudinally along the car body, and the secondary air duct 3 is composed of hollow long strip profiles , the inner end sidewall of the secondary air channel 3 is provided with a secondary air channel air inlet 31 along the longitudinal gap, and the secondary air channel air inlet 31 is connected with the air outlet of the main air channel 2 through the connecting air channel 4, the secondary air channel 3 The side wall of the outer end is longitudinally provided with secondary air channel air outlets 32, and the distribution density of the secondary air channel air inlets 31 is lower than the distribution density of the secondary air channel air outlets 32. The roof steel structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com