Efficient method for repairing rolling mill rack online and movable boring-milling machine

A rolling mill archway, boring and milling machine technology, applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of long installation time, small cutter head diameter, low alignment accuracy, etc., to save adjustment time, The effect of large cutterhead diameter and unique seating method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

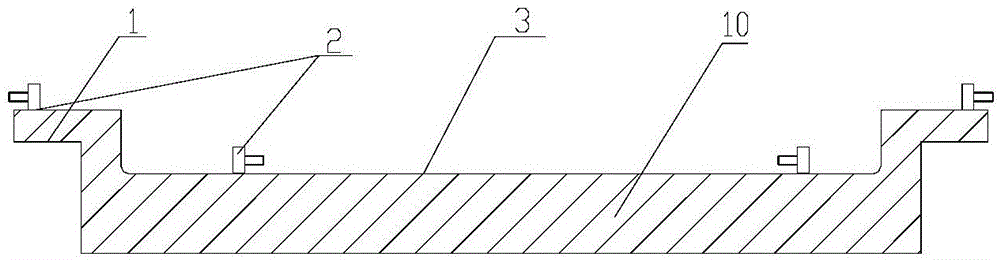

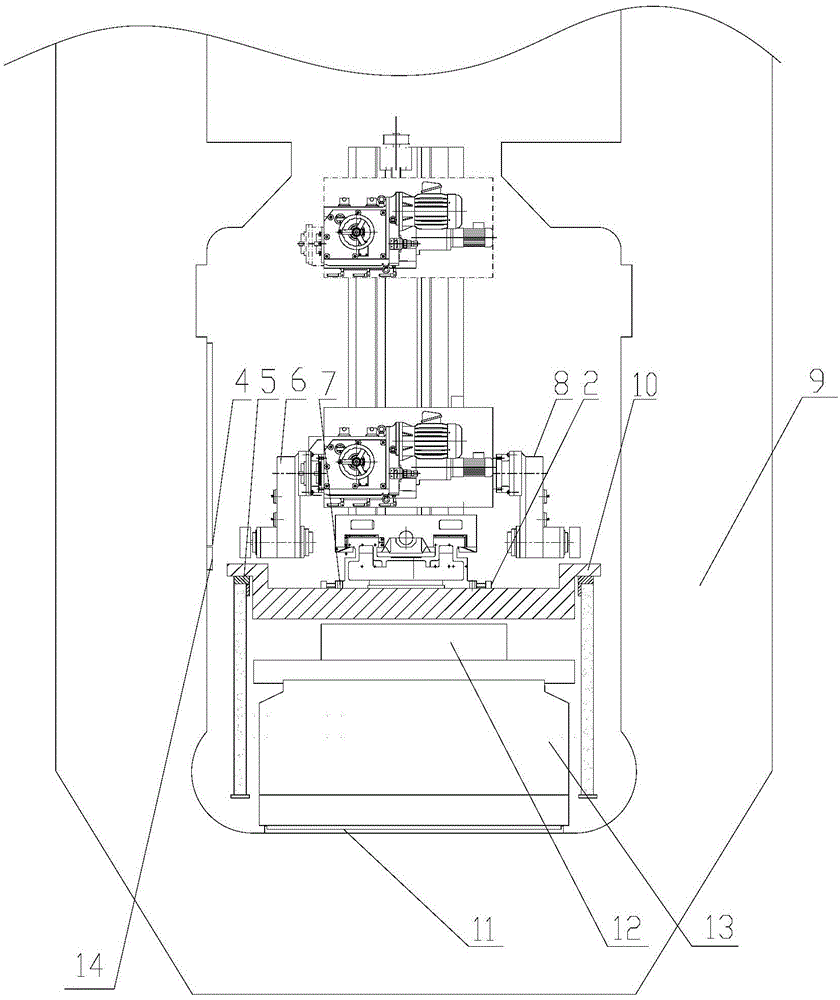

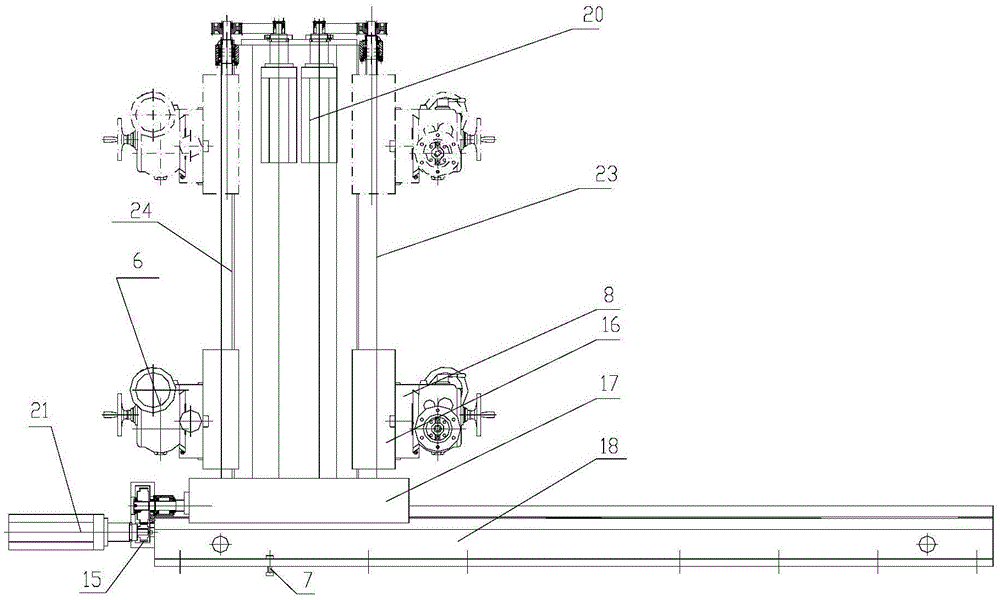

[0040] Such as Figure 3-4 As shown, the movable boring and milling machine used in the efficient method of online repairing the rolling mill archway includes an X-axis guide rail 18, the bottom surface of the X-axis guide rail 18 is provided with a height-adjusting top screw 7, and an X-axis slide table 17 is provided on the X-axis guide rail 18. Left and right y-axis guide rails 24, 23 are provided on the shaft slide table 17, digital display grating rulers are provided on the X-axis guide rail and the y-axis guide rail, and the X-axis slide table 17 is driven by the X-axis servo motor 21, and the left and right y Y-axis slides 16 are respectively arranged on the axis guide rails, each side Y-axis slides are driven by respective Y-axis servo motors 20, left milling heads 6 are arranged on the left Y-axis slides, and right Y-axis slides are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com