Two-dimension code watermark anti-counterfeiting paper and manufacture method thereof,as well as watermark cylinder mould

A manufacturing method and two-dimensional code technology, applied in the direction of papermaking, paper machine, paper machine wet end, etc., can solve the problems of anti-counterfeiting paper with two-dimensional code, watermark paper without two-dimensional code, etc., to achieve exquisite production, The effect of broadening the market application field and stabilizing the country's financial and social order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides an anti-counterfeit paper with a two-dimensional code watermark, a method for manufacturing the anti-counterfeit paper, and a watermark cage used.

[0038] The anti-counterfeiting paper with the two-dimensional code watermark provided by this embodiment is as follows: figure 1 As shown, the size of the two-dimensional code watermark is about 10-100mm, and predetermined anti-counterfeiting information can be recorded therein, and can be identified and detected by the detection device.

[0039] The above-mentioned anti-counterfeit paper with two-dimensional code watermark is prepared according to the following steps:

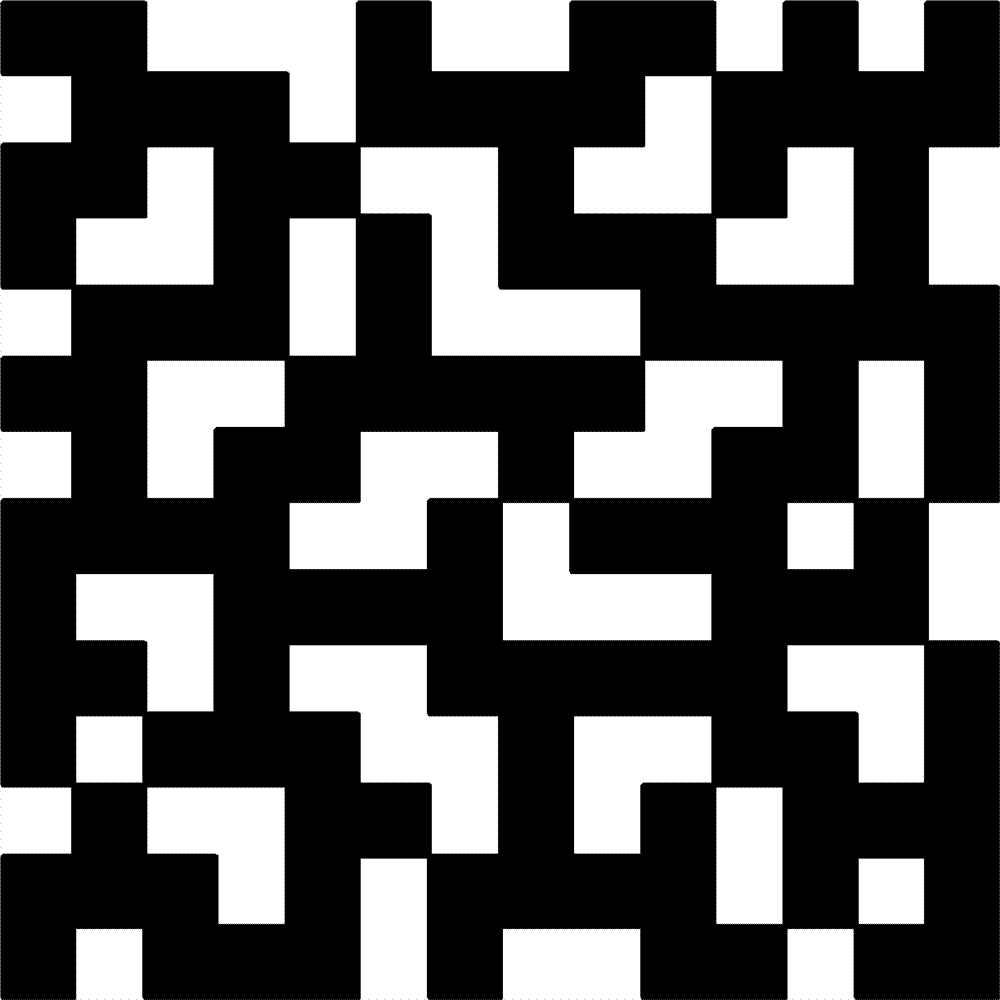

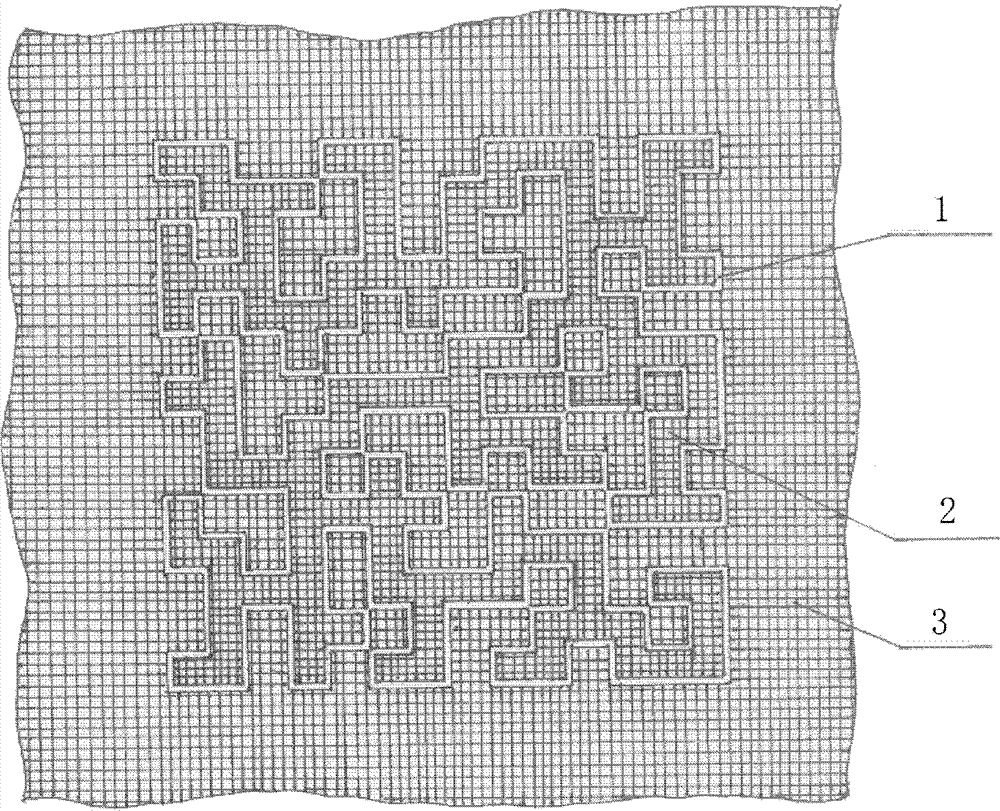

[0040] according to figure 2 The pattern of the two-dimensional code shown cuts the copper sheet and the copper mesh to obtain the watermark template, wherein the two-dimensional code pattern is composed of several small squares, the four edges of each square are copper sheets 1, and the central part is Copper mesh 2 can also be ...

Embodiment 2

[0045] This embodiment provides an anti-counterfeiting paper with a one-dimensional barcode watermark and a two-dimensional code watermark, its manufacturing method and the adopted watermark cage.

[0046] This embodiment provides a composite watermark composed of a one-dimensional barcode watermark and a two-dimensional code watermark in the anti-counterfeiting paper, and the size of the composite watermark is about 10×20-100×200mm 2 , may be recorded with predetermined anti-counterfeiting information.

[0047]The above anti-counterfeiting paper with one-dimensional barcode watermark and two-dimensional code watermark is prepared according to the following steps:

[0048] according to Figure 5 The patterns of one-dimensional barcode and two-dimensional code shown (the three parts in the middle are two-dimensional codes, and the parts on both sides are one-dimensional barcodes). Composed of several narrow lines, the two-dimensional code pattern is composed of several small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com