Manufacturing method of sesame oil

A production method and technology of jasmine oil, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of unsatisfactory pressing and processing methods, not very strict quality control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

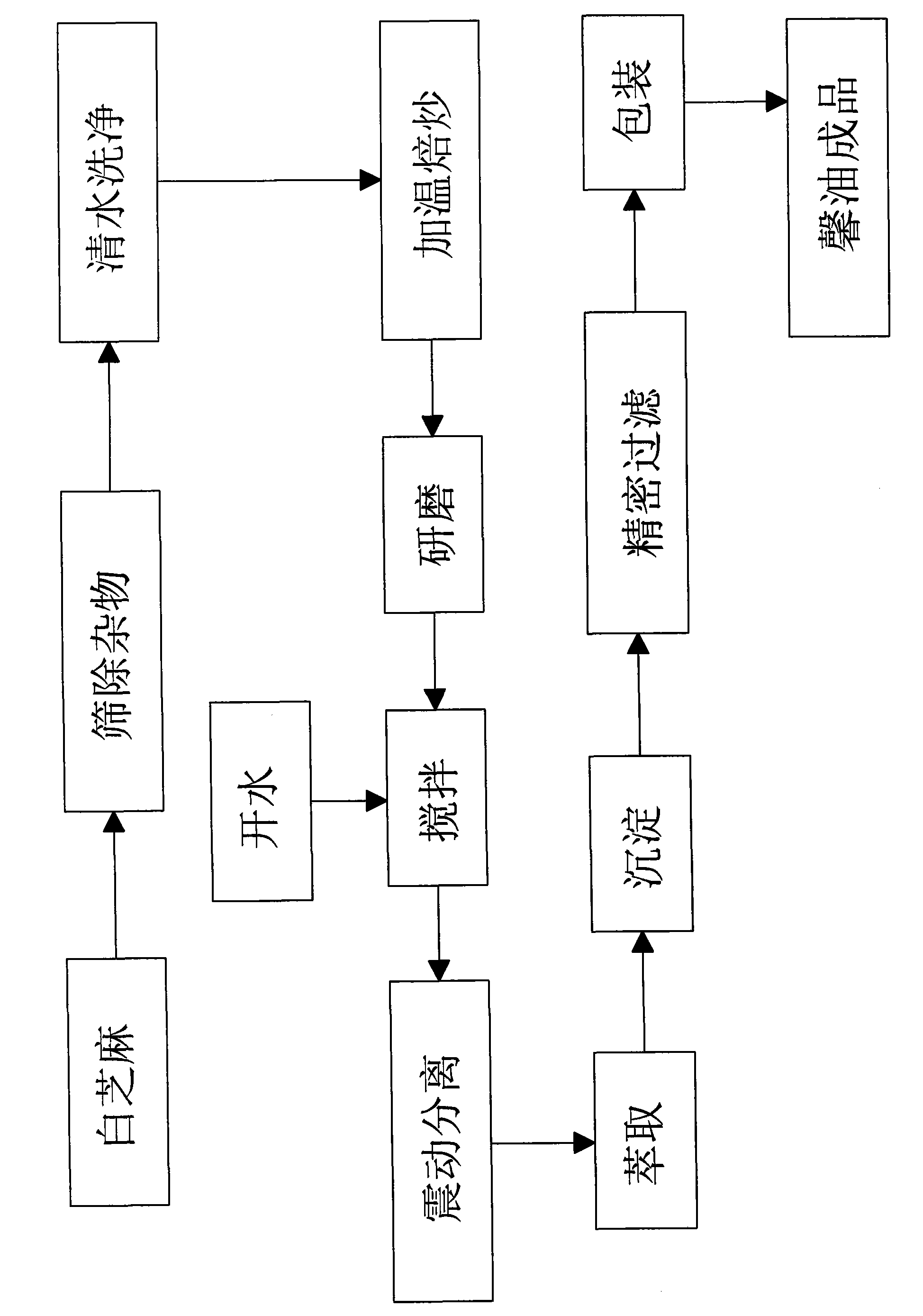

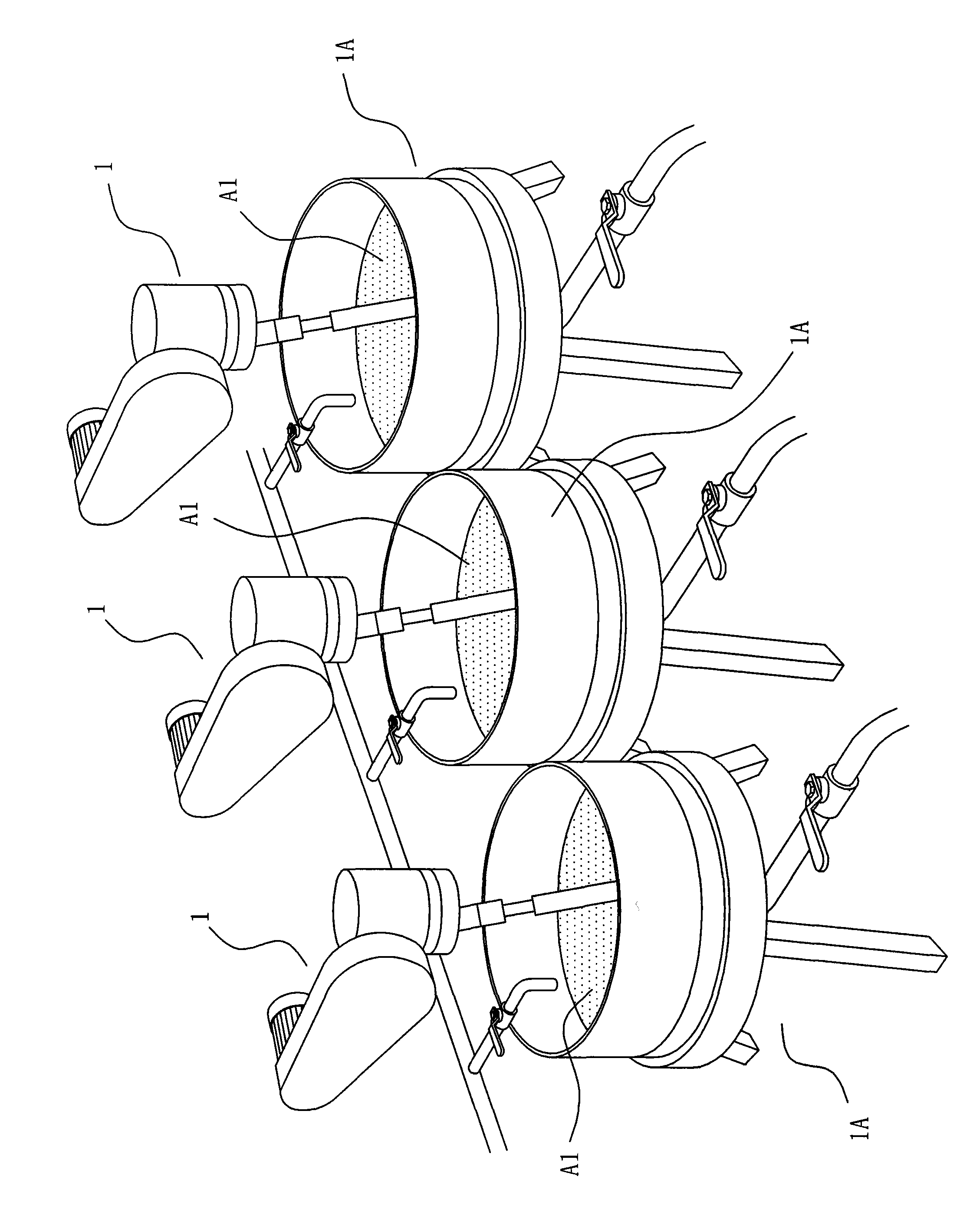

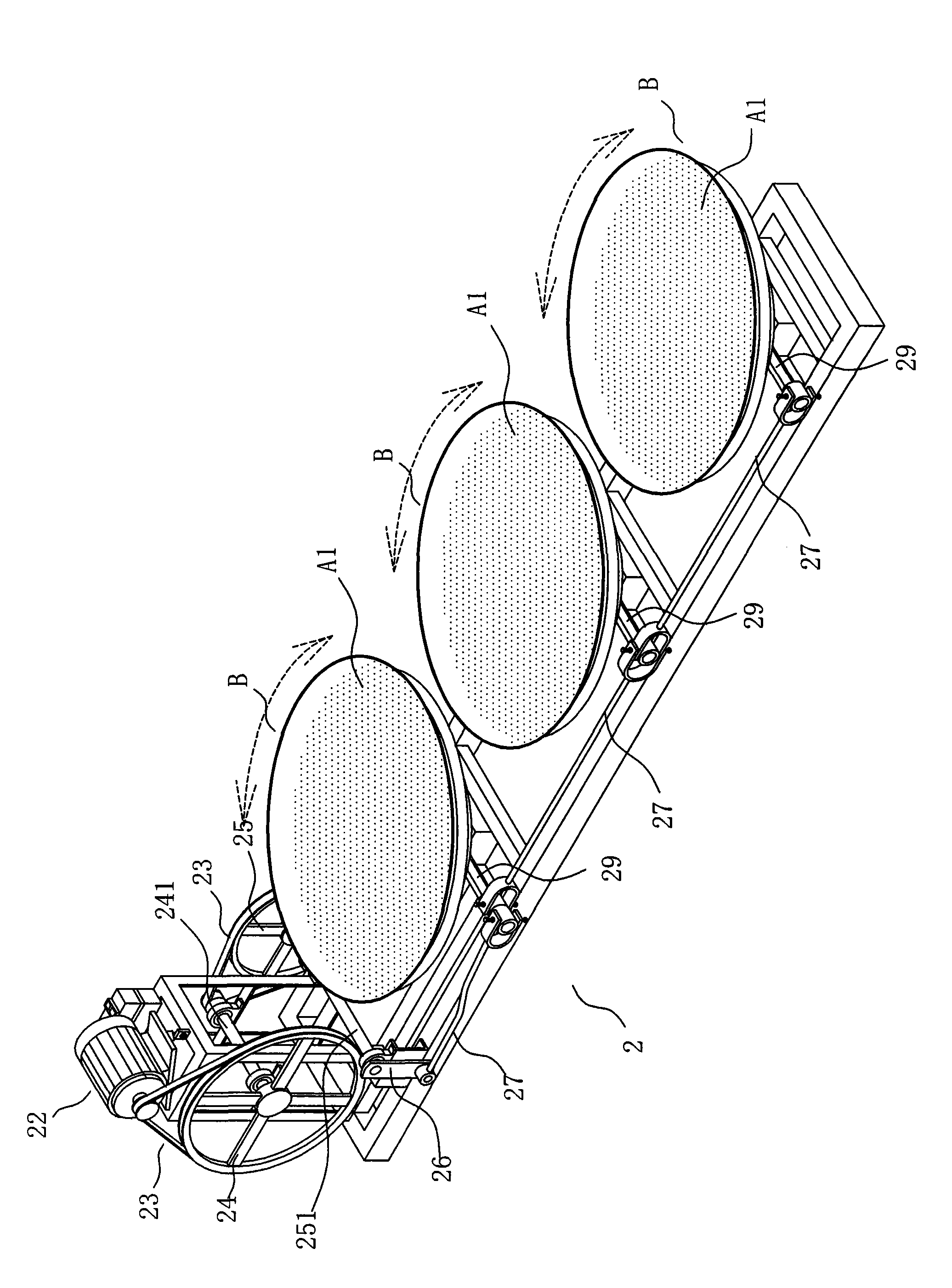

[0011] First of all, please refer to the figure 1 As shown in the detailed description: a method for making jasmine oil of the present invention is based on white sesame as a material. First, a predetermined amount of white sesame material is first screened to remove impurities, then washed with clean water, and then put into a heating device. Do heating and roasting, after the roasting and ripening is completed, grind it into sesame powder A1, then move it to the stirring container 1A, mix it with boiling water, and then use the stirring device 1 to stir it (such as figure 2 ), so that the oil A2 in the sesame is forced out of the body of the sesame powder A1, because the sesame powder A1 and the oil A2 are mixed together, so the sesame powder A1 is made by the vibrating separation device 2 It forms a vibration effect with its grease A2 (such as image 3 ), that is, the vibrating separation device 2 is to set up a power motor 22 on one side of a machine 21, so that the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com