Punching die for machining and punching of mount support of front safety air bag

A technology for installing brackets and airbags, applied in the field of stamping dies, which can solve problems such as simple structure, inability to complete stamping operations, and inability to align the lower die base, etc., to achieve the effect of reducing scrap rate and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

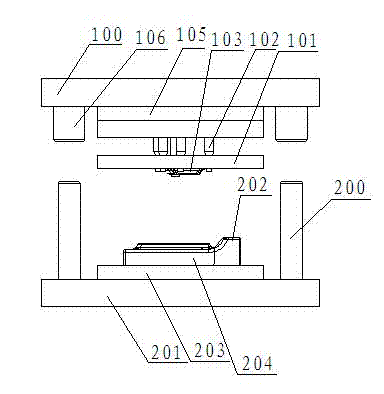

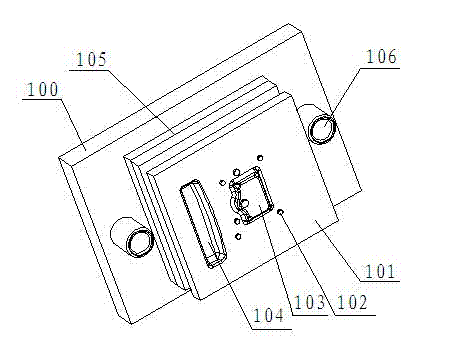

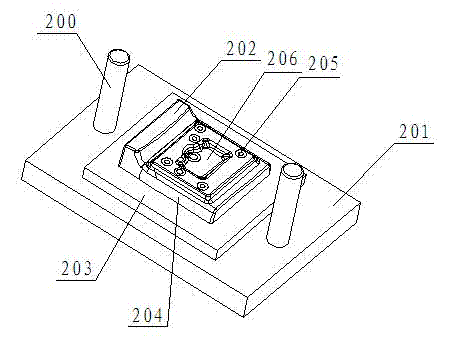

[0013] like figure 1 -Shown in -3, the stamping die that is used for the punching processing of front safety air bag mounting bracket has upper die holder 100 and lower die holder 201, and the bottom both sides of upper die holder 100 is provided with positioning sleeve 106, and the lower die holder 201 Positioning rods 200 are arranged on both sides of the top, and when the upper die base 100 and the lower die base 201 are in a bonded state, the positioning rods 200 extend into the positioning sleeve 106 .

[0014] The bottom of the upper die base 100 is equipped with a punch 105, the punch 105 is equipped with a punch 102, the bottom of the punch 105 is provided with a blocking plate 101, the punch 102 is installed in the punch 105, passes through the blocking plate 101 and stretches out. In one part, the part of the blocking plate 101 where the punch 102 passes is provided with a protruding structure 103 , and one side of the blocking plate 101 is provided with a rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com